SAE 1010 1018 1020 1022 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SAE 1010 1018 1020 1022 Carbon Steel Round Bar

Products Details

Material | AISI 1010, S10C,1.0330,10# | Round bar | Dia(mm) | Max 700 |

Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | Max 12000 | |

Heat treatment | Normalized / Annealed / Quenched / tempered | Plate bar | Thickness(mm) | Max 200 |

Delivery condition | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | Width(mm) | Max 3000 | |

Test | Ultrasonic test according to SEP 1921-84 D/d | Length (mm) | Max 12000 |

Chemical Composition

Standards: ASTM,JIS,GB,EN(DIN,BS,NF)

Grade | C | Si | Mn | Cr | Ni | Cu |

AIAI 1010 | 0.07~0.13 | ≤0.07 | 0.25~0.50 | ≤0.15 | ≤0.30 | ≤0.25 |

Delivery condition

EAF+LF+VD+(ESR), rolled / forged, annealed / Q+T, black/peeled/turned, UT tested

Application

Carbon steel rod applies to chemical industry, shipping industry,manufacturing industry, construction, decorate industry, electric power, pump shafts, sanitary wares, furniture handles, boiler, high temperature resistant,low temperature resistant,corrosion resistant

Sales Information

Material | High Quality Carbon Structural Steel 1010 |

Size | Diameter:10-700mm Length:6000mm-12000mm |

Origin place | Made In China |

Delivery Condition | Hot rolled, cold drawn, forged |

Surface require | Black, grinding, bright, polish |

Heat treatment | Quenched, Tempered, annealed |

Packing | Seaworthy packing ,wooden case ,carton,woven bag or at client's requires |

Delivery time | According to order’s quantity. |

Trade Term | EXW,FOB,CIF |

Payments | T/T or L/C at sight |

Port | China main Port, such as shanghai, Dalian, Shenzhen port. |

MOQ | 30 Metric Ton |

Main Products

AlloyStructural Steel | 5115, 5120, 5130, 5140, 5145, 4118, 4130, 4135, 4140, 4142, 4320, 4340, 4720, 6150, 8620, E9310,etc. |

Carbon Structural Steel | 1010, 1020, 1035, 1045, 1055, 1065,etc. |

Stainless Steel | 201, 202, 301, 302, 304, 305, 316, 316L, 317, 321, 410, 420, 434, 630,etc. |

Tool Steel | H13, D2, 01, D3,H21, P20, M2,etc. |

Bearing Steel | 52100,8620,4320,9310,440C,M50, etc. |

Spring Steel | 5155,5160,6150,9260,SUP6,SUP7,54SiCr6, etc. |

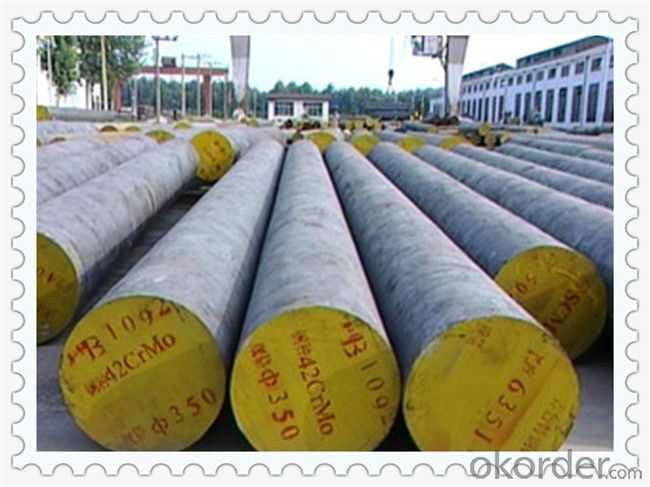

Products Show

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

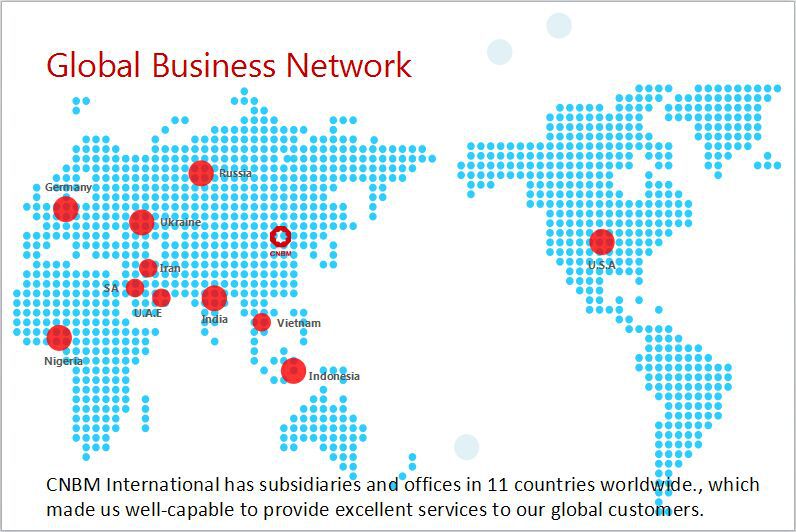

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What are the disadvantages of using steel round bars?

- Using steel round bars in certain applications has several drawbacks. Firstly, they are relatively heavy compared to materials like aluminum or plastic, which can be problematic when weight restrictions or easy transportation are important factors. Secondly, steel round bars are prone to corrosion, particularly in environments with high moisture, humidity, or exposure to certain chemicals. This can cause the material to degrade over time, reducing its strength and durability. To address this issue, additional measures such as coatings or regular maintenance may be necessary, increasing the overall cost and effort. Moreover, steel round bars may not be suitable for applications that require electrical insulation due to their conductivity. This can be a disadvantage when electrical conductivity needs to be avoided. Lastly, steel round bars may not be as visually appealing as materials like wood or decorative metals. While this may not be a significant drawback in some applications, it can be a disadvantage in situations where aesthetics are important, such as architectural or interior design projects. In conclusion, while steel round bars have widespread use and offer numerous advantages such as high strength and durability, it is crucial to consider these disadvantages in specific applications to ensure the most suitable choice of materials.

- Q: What are the different types of steel round bars used in the power generation industry?

- Different applications in the power generation industry utilize various types of steel round bars. These round bars are carefully selected for their distinct properties and characteristics, which are essential for different power generation processes. Commonly used types of steel round bars in the power generation industry include: 1. Carbon Steel Round Bars: These round bars are extensively used due to their affordability, strength, and ease of fabrication. They find applications in power generation equipment like turbines, generators, and boilers. 2. Alloy Steel Round Bars: Alloy steel round bars are created by combining carbon steel with elements such as chromium, nickel, and molybdenum to enhance their mechanical properties. These bars offer increased strength, corrosion resistance, and heat resistance, making them suitable for high-pressure and high-temperature applications in power plants. 3. Stainless Steel Round Bars: Stainless steel round bars possess high corrosion resistance and excellent heat resistance. They are commonly employed in power generation equipment that comes into contact with water or steam, such as condensers, heat exchangers, and valves. 4. Tool Steel Round Bars: Tool steel round bars are renowned for their exceptional hardness, wear resistance, and toughness. They are frequently used in power generation equipment that undergoes frequent machining, cutting, or forming processes, including drilling equipment and turbine blades. 5. High-Speed Steel Round Bars: High-speed steel round bars are specifically designed to withstand high temperatures while maintaining their hardness and cutting ability at elevated speeds. They find applications in power generation equipment like cutting tools, drills, and milling machines. 6. Duplex Steel Round Bars: Duplex steel round bars combine austenitic and ferritic stainless steels, offering outstanding strength, corrosion resistance, and weldability. They are commonly utilized in power plants for piping systems, pressure vessels, and heat exchangers. It should be noted that the specific type of steel round bars utilized in the power generation industry can vary depending on the requirements and operating conditions of each power plant. Therefore, it is crucial to consult with engineers and experts to determine the most suitable type of steel round bars for a particular power generation application.

- Q: How to determine the welding seam height of steel plate and steel bar?

- How to determine the welding seam height of steel plate and steel bar?:If the steel plate surface and steel end vertical welding, welding angle height depends on the diameter of the steel, general welding angle height is 0.7 times the diameter of reinforcement;

- Q: What are the different types of surface treatments for steel round bars?

- Steel round bars can be treated in several ways to enhance their properties and suit different applications. Some commonly used treatments for steel round bars include: 1. Zinc coating, also known as galvanization, provides excellent corrosion resistance. It is often used in outdoor and marine applications. 2. Black oxide coating chemically converts the surface of the steel round bars to a black iron oxide layer, offering enhanced corrosion resistance and an attractive black finish. This treatment is popular for decorative purposes. 3. Grinding is a surface treatment that involves using abrasive materials to remove the outer layer of the steel round bars. This process improves the surface finish, making them smoother and more visually appealing. 4. Shot blasting involves propelling small metallic or non-metallic particles at high velocity onto the surface of the steel round bars. It effectively removes impurities like mill scale and rust, resulting in a clean and uniform surface. 5. Chrome plating deposits a layer of chromium onto the surface of the steel round bars, providing excellent corrosion resistance and a polished, mirror-like finish. This treatment is commonly used when aesthetics and corrosion resistance are important. 6. Powder coating involves applying a dry powder electrostatically to the steel round bars, which is then cured under heat. This treatment creates a durable and visually appealing finish that is resistant to corrosion, chemicals, and UV rays. 7. Passivation is a chemical treatment that removes iron and other contaminants from the surface of the steel round bars. It leaves behind a clean and corrosion-resistant layer. Passivation is particularly important in industries such as medical and food, where cleanliness and corrosion resistance are crucial. These examples highlight the range of surface treatments available for steel round bars. The choice of treatment depends on specific requirements such as corrosion resistance, aesthetics, and durability.

- Q: Embedded bolts M24 why use M25 round steel?

- Such as using 24 of the round steel, worried about the surface quality of steel when the processing can not be nominal diameter 24 of the standard thread, of course, the election is too large and wasteful, so generally choose 25 of the round bar,

- Q: How are steel round bars used in the automotive industry?

- Steel round bars are commonly used in the automotive industry for a variety of applications due to their strength, durability, and versatility. One of the main uses of steel round bars in the automotive industry is for the production of crankshafts. Crankshafts play a crucial role in converting the reciprocating motion of the pistons into rotational motion, powering the vehicle. Steel round bars are ideal for this application as they offer high tensile strength, excellent fatigue resistance, and the ability to withstand high torque loads. Steel round bars are also used in the manufacturing of axles. Axles are responsible for transferring power from the engine to the wheels, supporting the weight of the vehicle, and providing stability. Steel round bars provide the necessary strength and rigidity required to handle the heavy loads and forces experienced by the axles. Additionally, steel round bars are utilized in the production of suspension components such as tie rods and sway bars. Tie rods are crucial for steering and maintaining proper alignment, while sway bars help to control body roll and improve handling. Steel round bars are preferred for these applications because they offer excellent torsional strength, allowing them to withstand the forces and stresses encountered during steering and suspension movements. Furthermore, steel round bars find use in the production of transmission shafts. Transmission shafts are responsible for transmitting power from the engine to the wheels via the gearbox. Steel round bars are well-suited for this application due to their high strength, resistance to bending, and ability to handle the rotational forces and torque generated by the engine. In summary, steel round bars are widely used in the automotive industry for various applications such as crankshafts, axles, suspension components, and transmission shafts. Their superior strength, durability, and versatility make them an ideal choice for these critical components, ensuring the safety, performance, and reliability of vehicles.

- Q: Can steel round bars be used for making interior components?

- Yes, steel round bars can be used for making interior components. They are often used in various applications such as handrails, furniture, fixtures, and decorative elements due to their strength, durability, and versatility.

- Q: What are the different grades of tool steel round bars?

- Tool steel round bars are available in various grades, each offering unique properties and characteristics to suit specific applications. Some of the different grades of tool steel round bars include: 1. W1: This is a water-hardening tool steel with relatively low carbon content. It is known for its excellent toughness and good wear resistance. W1 tool steel round bars are commonly used for cutting tools and woodworking tools. 2. O1: O1 tool steel round bars are oil-hardening tool steel with high carbon content. They have good wear resistance, high toughness, and excellent dimensional stability. O1 tool steel is often used for punches, dies, and cutting tools. 3. A2: A2 tool steel round bars are air-hardening tool steel with medium carbon and chromium content. They offer good wear resistance, excellent toughness, and high dimensional stability. A2 tool steel is commonly used for blanking and forming dies, as well as shear blades. 4. D2: D2 tool steel round bars are high-carbon, high-chromium tool steel with excellent wear resistance and good toughness. They offer high resistance to abrasive wear and are often used for making cutting tools, punches, and forming dies. 5. M2: M2 tool steel round bars are high-speed steel with a significant amount of tungsten, molybdenum, and vanadium. They have exceptional wear resistance, high red hardness, and good toughness. M2 tool steel is typically used for high-speed cutting tools, drill bits, and machining tools. 6. S7: S7 tool steel round bars are air-hardening shock-resistant tool steel. They have high impact toughness, good wear resistance, and excellent heat resistance. S7 tool steel is commonly used for applications that require high shock resistance, such as chisels and hammers. These are just a few examples of the different grades of tool steel round bars available in the market. The choice of grade depends on factors such as the specific application, desired hardness, wear resistance, toughness, and heat resistance required. It is important to consult with a knowledgeable supplier or metallurgist to determine the most suitable grade for a particular application.

- Q: Are steel round bars suitable for plumbing applications?

- Steel round bars are indeed a suitable option for plumbing applications due to their durability and strength. This material is particularly well-suited for plumbing systems that necessitate high pressure and load-bearing capabilities. Plumbing components like pipes, fittings, valves, and supports can all be crafted from steel round bars. Its resistance to corrosion and long-lasting nature make it a popular choice in water supply systems, underground piping, and industrial plumbing. Nevertheless, it is crucial to carefully consider the specific requirements of each plumbing application, including factors like water quality, temperature, and compatibility with other materials. Furthermore, the proper installation and maintenance of steel round bars are essential for ensuring their effectiveness and longevity in plumbing systems.

- Q: Are steel round bars recyclable?

- Indeed, recyclability is a characteristic inherent to steel round bars. Steel, being of immense value and easily recyclable, is among the most frequently recycled materials worldwide. Once steel round bars have served their purpose, they may be gathered and dispatched to a recycling facility. Within this facility, the round bars are subjected to the melting process, resulting in their conversion into novel steel products. Remarkably, this cycle can be perpetually repeated without any detrimental impact on the steel's quality. By choosing to recycle steel round bars, not only do we aid in the preservation of natural resources and the reduction of waste, but we also contribute to energy conservation and the mitigation of greenhouse gas emissions as opposed to the production of steel from raw materials.

Send your message to us

SAE 1010 1018 1020 1022 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords