High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

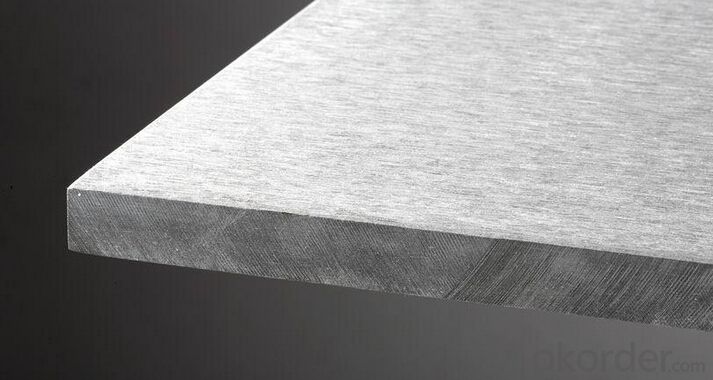

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q: Cement board spray really stone paint

- It is recommended to use the steel structure to do the foundation, first by 4.5 meters high 5 meters wide welded into the door type, and then use the GRC production of cement board (which vertical laying 6 PCT or 8 PCT steel, solder joints) welded to the steel structure, the surface Treatment is waterproof putty and spray really stone paint!

- Q: Bathroom wood panels on the aluminum plate opened, how do? Bathroom wood panels on the aluminum plate opened, how do?

- The bathroom is relatively dark and dark, available light steel keel aluminum plate hanging ceiling, light and durable moisture-resistant, and not easy to deformation, the price is not expensive.

- Q: What is the process of using a cement pressure plate to dry the tile? What do I need to know about the specifications of the light steel keel, how thick the board

- This process is the traditional practice, said in front of the keel of course, is 50 and 75 of the main, depending on the wall area, keel spacing is the same, a large area of 400-600MM can accept, if the package, duct Of course, depending on the size of the pipeline.

- Q: Can cement fiber board be attached to fire board?

- Can be affixed, with Porsche stickers, completely no problem. I am glue factory manufacturers, if you need the right glue

- Q: where can i buy national gypsum perma base cement board?

- Permabase Cement Board

- Q: This is when you are installing tiles over existing cement patio. Idk if it's a board, it seemed bendable. I saw it on HGtv And I can't remember what it's called

- Made by Schluter tile systems and I believe what your referring to Ditra, Flexible orange mat. Any questions you can e mail me through my avatar and check my qualifications there, GK

- Q: I've already got the cement board down, taking it back up would mean messing with the toilet flange, which means plumbing, and that sucks. Plywood was in pretty good condition. Thanks in advance!

- If you don't apply mortar, the tile will shift around, come up, etc. It's best to go ahead and do it right when you are initially laying it therefore saving yourself a costlier repair. Good luck.

- Q: Home studio decoration, do noise wall, is the effect of good gypsum board or cement fiber pressure plate effect is good

- Fiber cement board is made of fiber, cement, quartz sand, additives, water and other inorganic substances, mixed molding, high temperature and high pressure steaming and special technology to deal with and made a variety of thickness, density products, 100% non-asbestos and other harmful Material, with high strength, large format, light, fire, waterproof and other excellent performance of the new environmentally friendly building plate. Green, 100% of the plate does not contain asbestos, formaldehyde and other harmful substances, in use will not produce toxic gases or radiation. Lightweight, sound insulation, the board light weight, high strength, good toughness, sound insulation effect, to meet all kinds of sound insulation requirements of the wall or barrier.

- Q: I have a small 4X2 area in which I need to re-tile. The area now is outdoors and is set inside of a concrete slab. Who ever installed the tiles before installed them like paver's where they backfilled the small area with sand (about 3). My question is can I use durock or another cement board to get a solid surface for tiling or do I need to refill the area with concrete? I don't know too much about concrete work which is why I am looking to use the cement boards.Thanks

- this area needs to be filled with easy to use Sak-crete and then float base for tile and them you can RE-tile and it should hold up for years ..... the hardware giants offer classes in tile setting and you can learn the correct

Send your message to us

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords