Fireproof Calcium Silicate Board for Rotary Kiln

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireproof Calcium Silicate Board for Rotary kiln Details:

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Type: | Non-Asbestos Fiber Cement B |

Packaging & Delivery

| Packaging Details: | wooden case in LCL, nake package in FCL |

| Delivery Detail: | 15 dyas after receipt of your deposit |

Product Description:

General information for Calcium silicate board:

CMAX calcium silicate products are classified under temperature between 650℃ to 1100℃, it’s an asbestos-free thermal insulation product.

Applications for Fireproof Calcium Silicate Board for Rotary kiln:

◆Reheating furnace

◆Annealing furnace

◆Transfer ladle

◆Rotary kiln

◆Glass tank

◆Shuttle kiln

◆Tunnel kiln

◆Aluminum melting and holding furnace

Main Product Features:

◆Low thermal conductivity

◆High thermal insulation value

◆High strength

◆High strength

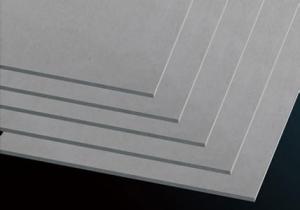

Product Specifications:

| Size | Standard Size | 1220*2440*20/22/25mm |

| Appearance | Surface | Surface:Un-sanded |

| Edge | Square | |

| Physical Properties | Density | 1.4-1.6g/cm3 |

| Bending Strength | 16-21Mpa | |

| Moisture Movement | <0.20%< span=""> | |

| Water Absorption | < 20% | |

| Water Contain | <10%< span=""> | |

| Thermal Conductivity | 0.18-0.3 w/(m •k) | |

| Non-combustibility | GB 8624-2006 Grade A1,CE EN 12467:2012 Grade A1 | |

| Water Impermeablility | Traces of moisture appeared on the under surface of the sheet,but no formation of drops of water on the underside of the sheet after 24 hours. | |

| Freeze-thaw | Not have cracking and layering after freeze-thaw cycles 25 times. | |

| Application | 20-25mm thickness is used for Floor & Mezzanine | |

| Average Bearing Loading(Refernce) | 2000kg/m2(distance between 12# Angle Bar is 610*610mm);1200kg/m2(distance between 12# Angle Bar 610*1200mm) | |

| Products Warranty | More than 20 years |

| Raw Material | |

| Cement | Quartz |

| Natural Fiber | Suspension |

| Composition of Finished Product | |

| Crystalloid of Calcium Silicate | Quartz |

| Calcium Carbonate | Cellulose |

FAQ

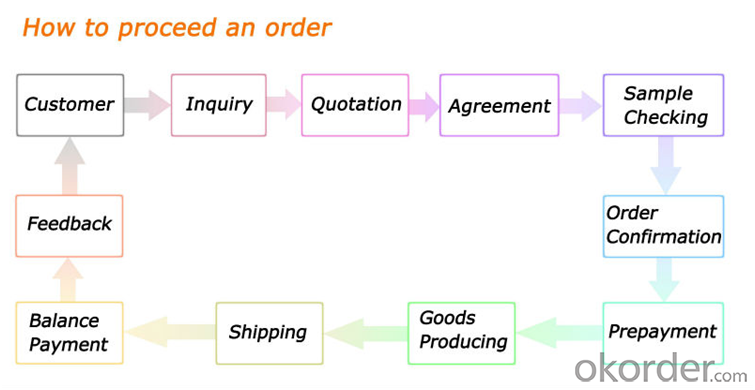

1. How to order ?

2.Can we accept OEM ?

YES! We can according your demand to produce.

3. Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, D&B and so on.

Our service:

üPrompt reply within 24 hours without delay by our specialized after-sale service sector.

üProvide high temperature solutions and professionals construction services for different fields for our customers.

üProvide the most reasonable logistics for customers to save every penny.

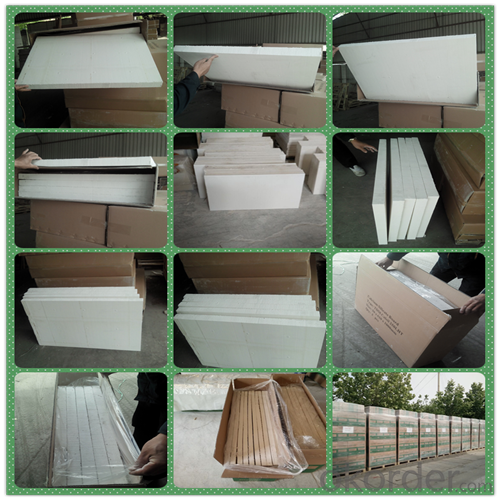

üProduction of goods are finished, thoughtful provide products and packaging photos for our customers.

Welcome to contact me for our Win-Win Cooperation!!!

- Q: Calcium silicate is afraid of high temperature

- Not afraid, high temperature materials

- Q: What is the difference between calcium silicate board and cement pressure plate?

- Is not the same thing, the cement board is cement as the main condensate material through the formation of natural conservation, high strength, but the deformation coefficient. Calcium silicate board is made of siliceous material and calcareous materials such as lime and quartz sand through high temperature and high pressure to form terrestrial monolithic inorganic crystals. Although the strength of cement board, but also generally more than 11 MPa, to meet the requirements. Deformation coefficient is small, fire rating for the highest "non-flammable". It is far more than the resistance of the cement fiberboard to the deformation resistance of the calcium silicate board. Because the calcium carbonate board cement content is not high, while the latter are basically cement. Cement is easy to deform. Please add points.

- Q: What is the use of high-temperature calcium silicate board? I want to find a material can be resistant to high temperature 1500 ℃, and must be pressure,

- Are you asking for ceramic or refractory bricks? Calcium silicate board is not able to fire more than 1000 degrees, and fire detection, only in a certain temperature and time the flame can not be greeted by the locusts, but not cracking, but the chemical Composition has long been changed, the intensity is certainly lost, do not say that fight against, there are problems with compression.

- Q: Seam method of effective calcium silicate board ceiling

- With non-woven, or kraft paper

- Q: What is the difference between silicon calcium board and sound-absorbing board?

- Silicon calcium board is a compact board, basically airtight. Relative to the sound-absorbing panels heavier and harder. Is a sealed plate. Mainly from the sound effects. That is to stop the sound on both sides of the space in the spread of space. Sound-absorbing board is porous multi-slit plate, basically ventilated. Most of the things can be directly through the plate to see the other side of the board thing. Mainly from the sound-absorbing effect, that is, to weaken a certain frequency in the board side of the amount of reflection. Very few sound-absorbing panels directly to do the partition, so the sound-absorbing panels are generally not used to deal with the sound problems on both sides of the board, only dealing with unilateral sound field.

- Q: Calcium silicate board can do outdoor waterproof wall directly?

- Calcium silicate board, including fiber cement pressure plate can only say that not afraid of water, is not able to waterproof. Indoor and outdoor wall with what waterproof material? It is recommended to use nano-silicone waterproofing agent. This is a national patent product, specifically for the inside and outside the wall of the waterproof, spray use, simple and convenient, reliable quality. Can also be used for large-scale new kitchen bathroom Erlang jump on the foot of the foot of the Dan project, as well as dry porous inorganic building materials on the surface of the waterproof. For example: the concrete wall, the ground, brick surface, natural stone surface, lime wall surface, spray after the formation of colorless permanent waterproof layer.

- Q: Koichi Chemical: How does calcium nitrate turn into calcium silicate in one step?

- And the total heat of silicon dioxide, because the generated CO2 is a gas, can volatilize and leave the reaction system, so the calcium carbonate can be converted to calcium silicate.

- Q: Calcium silicate brand Tingduo, but do not know which brand quality is relatively strong. More

- The top few are Eide, Taiwan Rong, Matsumoto, East, the new elements, such as Germany and Germany more well-known, quality is also excellent

- Q: I recently learned to decorate the smallpox, I understand that the general is to use keel + silicate rafts to promote the Wo drum drums to support the calcium plate. Will the current maximum number of people is 6%, or 8 PCT thickness of calcium silicate board? More

- Of course, is 6 cm

- Q: Ceiling silicon calcium board and mineral wool board which is better

- Mineral wool board ceiling than silicon calcium plate ceiling are different. It is recommended to use calcium silicate board, the first mineral wool board thickness, increased keel pressure, easy to cause the ceiling subsidence. Second, mineral wool board which is easy to produce some insects. The third mineral wool board fire performance without calcium silicate board is good, the fourth mineral wool board damp easily yellow, hygroscopicity is not good. And calcium silicate board will not have the above shortcomings, if it is ceiling ceiling 600 * 600, then the thickness of calcium silicate board 4mm can achieve the effect of mineral wool board 15mm thickness, while the biggest advantage of calcium silicate board is not combustible A class of fire, moisture absorption is very good, environmentally friendly building materials. Silica calcium board with fire, moisture, noise, heat insulation and other properties, in the case of indoor air humid to attract water molecules in the air, air drying, but also the release of water molecules, you can properly adjust the indoor dry, humidity, increase comfort The Natural gypsum products are also special fireproof materials, in the flame can produce endothermic reaction, while the release of water molecules to prevent the spread of fire, and will not break down to produce any toxic, aggressive, suffocating gas, it will not produce Any fuel or flue gas. Mineral wool board is made of mineral fiber cotton as raw material, the biggest feature is a very good sound absorption, heat insulation effect. Its surface with knurling and relief and other effects, patterns are filled with stars, caterpillars, cross flowers, center flowers, walnut lines, strip lines and so on. Mineral wool board can sound insulation, heat insulation, fire, any products are not asbestos, harmless to the human body, and anti-sagging function.

Send your message to us

Fireproof Calcium Silicate Board for Rotary Kiln

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches