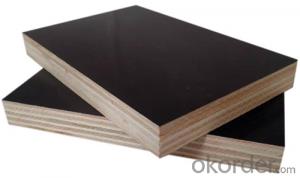

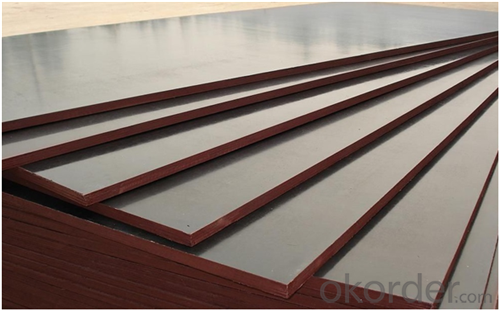

Different Color (Brown, Red or Black) Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywood

· Place of Origin: Shandong, China (Mainland)

· Model Number: film faced plywood

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E2, E0,E1,E2,

· Plywood Type: 9-Ply Boards

· Film faced plywood thickness: 18mm

· Moisture: 8~10%

· Species Core: Poplar, Combi, Hardwood, Birch

· Standard Size: 1220x2440mm,1250x2500mm

· Glue: Melamine WBP, Phenolic WBP,MR

· Film: Brown, Red, Black

· Cycle Life: about 6~10 repeated using times

Packaging & Delivery

Packaging Details: | film faced plywood Inner packing: Wrapped with 0.2mm plastic bag Outer packing: Pallets are covered with 2.0 mm plywood and then steel tape for strength. |

Delivery Detail: | within 15 days after order confirmed |

Product Description:

Film faced plywood is mainly made up of eucalyptus plywood, poplar plywood or eucalyptus and poplar plywood, it is economic and practical for the construction concrete pouring, for it could be the face panel for any formwork system, for example, steel frame formwork system, single side formwork system, timber beam formwork system, steel props formwork system, scaffolding formwork system, etc.

Product features:

1. Light Weight: We choose the high grade eucalyptus and poplar as the basic material, they are very light, so film faced plywood is convenient for transporting, and only one person could delivery single formwork by hand.

2. Easy To Cut: the plywood is easy to cut, so according to the construction, the formwork could be cut into the required size.

3. Re-used: Film faced plywood could be used 8-10 times.

4. Multi Using: Film faced plywood could be used for wall, slab, column, beam and bridge concrete pouring etc.

5. No Deformation: Film faced plywood is also whole but not deformation and chipping after 72 hours cooking in boiling water.

6. High Quality Film: It protect the formwork surface from the corrosion and makes the formwork durable, improves the flatness of the concrete surface and makes the concrete surface save the second time plastering, so it could save a lot cost of construction.

Product Specification:

Product Name | Film faced plywood | ||||

F/B | Black film, brown film, red film | ||||

Grade | Construction grade(one/two time hot press) | ||||

Core | Poplar, hardwood, birch, pine, combi , and so on | ||||

Glue | melamine and WBP | ||||

Thickness | 9-25mm | ||||

Specification | 1220x2440mm, 1250x2500mm,915x1830mm | ||||

Moisture Content | 8-10% | ||||

Package | Standard export packing | ||||

Press | one times press/two time press grade | ||||

MOQ | 1x20GP | ||||

Price Terms | FOB, CIF, CFR | ||||

Payment | T/T 30%, irrevocable LC | ||||

Delivery Time | Within 15 days after order confirmed | ||||

Supply Capacity | 4500 cbm/month | ||||

Usages | Can be widely used for building concrete, etc | ||||

Remarks | Top class equipment with top class produce technique; Credit first, fair trading | ||||

Formaldehyde Emission Standards | E2<30mg/100kg E1<9mg/100kg E0<5mg/100kg | ||||

Thickness(mm) | Layers | Standard size | Large size | ||

min. (mm) | max.(mm) | min.(mm) | max.(mm) | ||

9 | 7 | 8.5 | 9.5 | 8.2 | 9.5 |

12 | 8 | 11.5 | 12.5 | 11.2 | 12.5 |

15 | 9-10 | 14.5 | 15.5 | 14.2 | 15.5 |

18 | 11 | 17.5 | 18.5 | 17.2 | 18.5 |

21 | 13 | 20.2 | 21.5 | 20.2 | 21.5 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: 100 thick 960 color steel sandwich board how much money one meter? What is the bulk density?

- This is not necessarily normal 8 kg, 10 kg

- Q: Rock wool color steel sandwich board rock wool bulk density

- 120 ~ 150kg / m ^ 3 Depending on the temperature difference, the temperature difference in the 130 ~ 180kg / m ^ 3 Attached to the industry standard

- Q: What brand of rock wool sandwich board is good

- Hai Zhen Hai Zhen company specializing in the production of rock color steel plate, glass magnesium color plate, aluminum honeycomb color plate, paper honeycomb color plate, polyurethane color plate, paper honeycomb color plate

- Q: Sandwich board ceiling how to build? What's the utility?

- Hello, as far as I know: the general price of a square in twenty or thirty dollars or so look. Sandwich panels are widely used in industrial non-load-bearing walls and civil buildings, roofs, ceilings and housing wall panels, machinery, electronics, chemical industry, insulation, , Medicine, biology, food, health and other clean room partition, ceiling, etc. for a single combination of Caigang sandwich panels. The sandwich plate molded part is a cured composition of a metal plate (or other material panel) made of two layers and a polymer formed by foaming directly in the middle of the panel and forming the insulating core. The above prices are network reference, the specific price to the actual purchase. Hope to help you

- Q: Does anyone know the reason why the sandwich panel is bubbling and partially degumming during the pressing process?

- Hydraulic press to suppress the plate, the bubble and local degumming these two phenomena are due to: 1, veneer moisture content is too high or dry uneven 2, the amount of glue is too large 3, buck faster or hot pressing temperature is too high 4, the degree of condensation is not enough resin 5, hot pressing time is insufficient

- Q: Color steel sandwich panels and C steel belongs to what industry

- Should be considered building materials it Make the house with the thing.

- Q: Color steel sandwich board glue is a mixture of vinyl and white plastic, resulting in a chemical reaction caused by sticky. Does anyone know the chemical name of black gelatin? Vinyl are basically imported, and that how is the deployment of white plastic? Is the sandwich used in the sandwich plate diluted? That color steel PU foam with the glue is not the same black and white glue generated reaction? Hope to receive professional mention.

- Vinyl for the polymerization of isocyanate components, and now the domestic is also good, white plastic for the polyol component, the formula I know

- Q: Color steel sandwich panel has what color?

- Highland and white ashes. Special colors can be customized

- Q: 7 meters span steel structure color steel sandwich panels roof, column, truss, purlins, respectively how much? What is the column spacing?

- Steel frame with No. 20 H steel, purlins C160, open to 4 meters or 6 meters, to reduce material loss.

- Q: Color steel polystyrene sandwich panel specifications 0.4 * 0.3 * 50mm, of which 0.3,0.4,50 size, respectively, where the size

- Do not know what you say 0.3,0.4 unit of measurement is rice or centimeters. If it is followed by the 50 mm unit that is consistent, it basically can not say it! However, on this color steel to understand the words, 50 mm refers to the thickness. 0.4,0.3 units should be meters, so that should be 0.4 meters long, 0.3 meters wide, 0.05 meters thick polystyrene board.

Send your message to us

Different Color (Brown, Red or Black) Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords