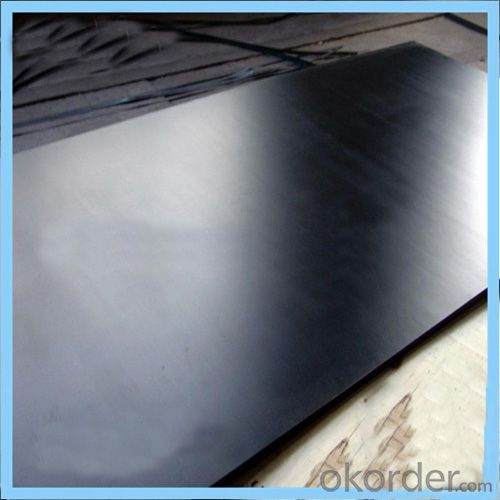

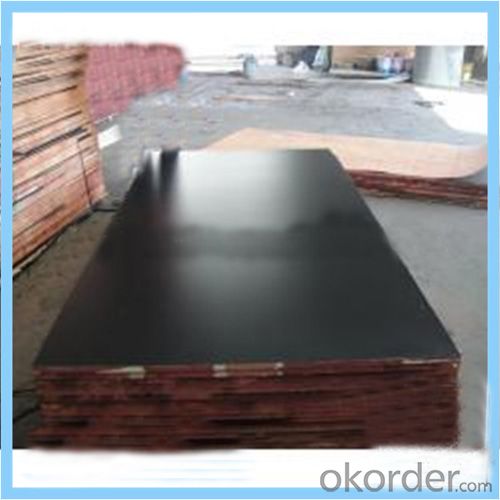

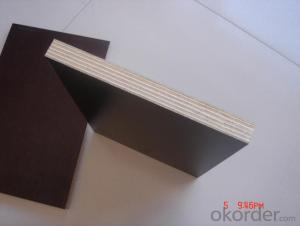

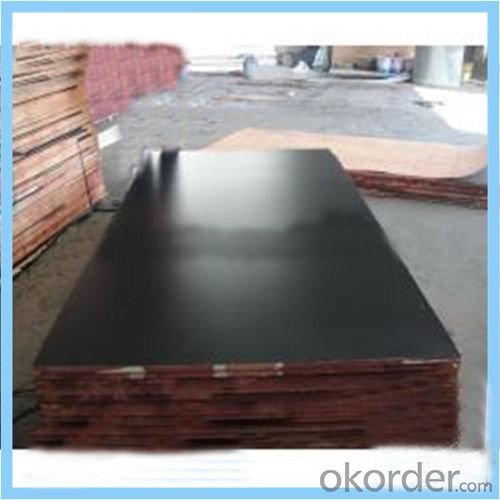

9mm & 12mm Black Film Faced Plywood for Nepal Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 53 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

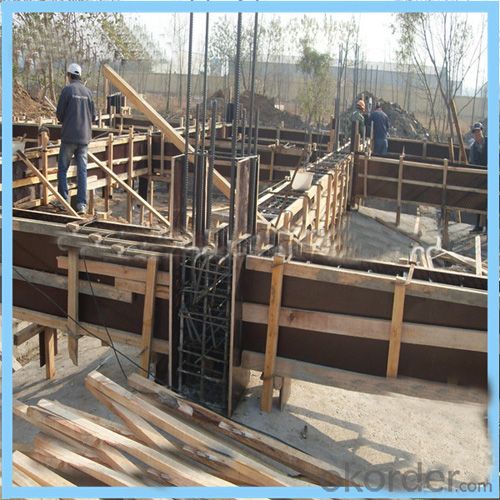

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Brand Name: CHANTA

· Model Number: Film Faced Plywood L003

· Usage: Outdoor, Outdoor

· Grade: First-Class, First-Class

· Main Material: Poplar, Poplar

· Formaldehyde Emission Standards: E1

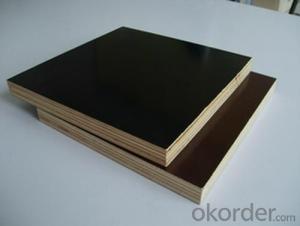

· Plywood Type: 13-Ply Boards, Film Faced Plywood

· Thickness: 9~20mm

· Moisture: about 12%

· Glue: WBP

· Certificate: CE, FSC, CARB, ISO9001:2000

· Film: Black/Brown

· Size: 1220x2440mm

Packaging & Delivery:

Packaging Details: | Inter packing: 0.20mm plastic bag;Outer packing: pallets are covered with plywood or carton and then steel strips for strength |

Delivery Detail: | within 20 days upon the receipt of L/C or T/T |

Product Description:

FILM FACED PLYWOOD

size | 1220*2440mm/1250*2500mm |

thickness | 6mm,9mm,12mm,13.5mm,15mm,18mm,21mm |

core | poplar,birch,hardwood,combi or as your request |

film | black /brown ,Anti Sip film |

density | 500-700kgs/cbm |

moisture | less than 12% |

Thickenss tolerance | +/-0.5mm |

Modulus of rupture | ≥30Mpa |

Modulus of Elasticity | ≥ 6000MPa |

packing | bulk or standard pallet packing |

delivery time | within 15 days after received the deposit |

payment | 30% deposit TT, L/C at sight. |

Nepal Market Plywood 9mm 12mm Black Film Faced Plywood

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Our Mission: provide customers with high quality and service!

- Q: Suzhou Yanmian sandwich board which is good?

- It is recommended to consider Suzhou Fu new purification equipment Technology Co., Ltd., the company is specialized in the purification equipment R & D and production, purification engineering design, purification engineering construction, purification project maintenance clean room vacuum cleaner, laminar flow hood FFU, clean shed and electrostatic products sales Comprehensive technical services of high-tech enterprises. It can provide professional air purification system engineering design for air electronics, biomedical, hospital operating room, fiber optic cable, food and beverage, precision instrument, semiconductor and new material application, air purification system engineering, air purification system engineering inspection and air Purification system engineering and technical services; according to the customer's actual requirements and the actual needs of the design, manufacture, installation of clean room systems and equipment. So you can consider buying and cooperating.

- Q: Is not allowed to use foam sandwich color plate

- Hello! Now the state banned the use of foam sandwich color steel plate, also known as foam sandwich panels, because the foam sandwich board fire rating is poor, the state is prohibited. Now the market generally use rock wool color plate, which is used instead of rock wool composite board, fire rating up to A level. There are also some high-end customers with polyurethane color plates instead of using them, so the cost may be higher. Choose a most suitable for their own sandwich color plate can be used. After all, who is not the wind to the wind, the ability to do so

- Q: What is the difference between the ecological board and the sandwich board? Which is used to decorate better, what is the price? What are the top ten brands of the two boards?

- The ecological board is made of natural mineral stone powder and natural fiber as the basic raw material, through the inorganic gel technology modification process, through the mold, natural curing molding for the environmental protection and energy saving new materials, which does not contain formaldehyde, toluene inorganic natural environmental performance, Combined with the surface of the natural texture and sustained and efficient negative oxygen ion release, to achieve its natural properties of green building materials. Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor.

- Q: Glass wool cotton color steel composite panels, also known as sandwich panels should be how to do re-test? Is it good to do it?

- Do the bare board re-test or do complex panel to see your design requirements and product record is how to prepare. Sometimes it is compound re-examination

- Q: Color steel plate wall how many meters a general support, corrugated color plate non-sandwich panels

- Is there any angle between the top and bottom of the color plate? If not, the two panels at the junction should be set up a support point. If there is, 2-3 sets of color board can be set up to support, depending on the size of the project area average annual wind. We usually set up a 2 support.

- Q: Sandwich composite panel and color steel tile difference which the high cost

- Sandwich panels cost high roof is usually 0.8 thick YX760 plate plate 6000 yuan / ton is calculated 49.5 yuan / square if you are processing, probably not more than 55 yuan / square; and sandwich panels are generally finished the purchase of the thinnest 50 thickness 1150 type of the board more 80 yuan / square and the installation fee because the sandwich plate is thicker than the color steel tile expensive. ???? But the use of sandwich panels is different from the color steel tiles, such as model rooms and the need for sound insulation of the plant (general foreign enterprises plant) will use sandwich panels; and if only to do storage, processing lines, non-heavy noise pollution recommended The cost of relatively low color steel tile ~ ~

- Q: We want to build the activities of the board room is used as a dormitory, what materials used sandwich board good? What is the price of polystyrene board and rock wool board? As a dormitory board room in the height of the national standard? How high should it be?

- Mainly to see the use of activities, fire or rock wool sandwich board is good

- Q: Sandwich board is 50,75,100,150, color steel thickness, casually one can.

- 50 thick: 45 ~ 75 yuan 75 thick: 53 ~ 87 yuan 100 thick: 62 ~ 95. Sandwich panel thickness is not limited. I am also about this. Because you are not very clear.

- Q: Pressure steel plate sandwich panel roof and wall construction structure how to mine construction

- This involves a lot of standards, such as GB50057, can not enumerate, if there are such projects can find cooperation, see more time to see the standard to understand.

- Q: Is the sandwich board harmful to the human body?

- No harm, just pay attention to fire

Send your message to us

9mm & 12mm Black Film Faced Plywood for Nepal Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 53 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords