1220*2440*18mm Film Faced Plywood for Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

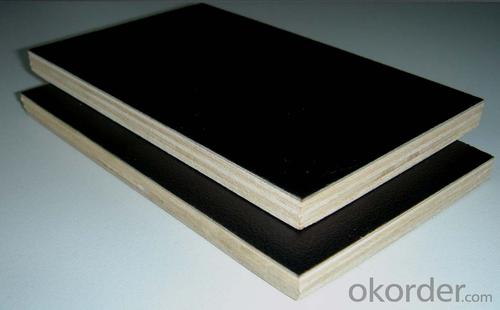

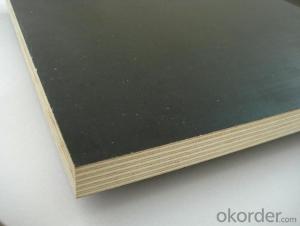

Item Name:Film Faced Plywood/Shuttering Plywood

Size:1220x1440mm,1250x2500mm

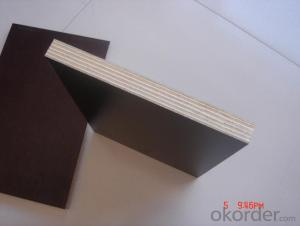

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,other thickness as requested

Description

Size | 1220x2440/1250x2500 |

Thickness | 12mm(9ply+2layers film) |

15mm(11ply +2 layers film) | |

18mm(13ply+2 layersfilm) | |

21mm(15ply+2 layers film) | |

25mm(17ply+2layers film) | |

Film | 125/40g Imported brownish film(Indonesia/Malaysia) |

180/60g chinesesblack film(made in china) | |

Core veneer | Poplar/birch combi(poplar + hardwood) |

Glue: | Type:I WBP(water boiling proof) |

TypeII MR(moisture resistance) | |

Physical Test | |

Moisture contents | Less than 12% |

Thickness Tolerance | +/-0.5mm |

Allowance in width& length | +/-0.2mm |

Diagonal Allowance Max | 3.0mm |

Bending strength(0 | Min.23.5N/mm2 |

Bending strength(90 | Min.19.5N/mm2 |

Features

1) Good Raw Materials and High quality

2) More repeated using times

3) Good packing and fast shipment

4) Delivery the right products according to different level of requirement

5) High performance/price ratio

FAQ

1.What's your company property ?

More than 10 factories to meet your various needs.

2.Free samples ?

Samples are free. As for the cost of courier , we will give back to you in the payment of the trial order .

3.What's your delivery time ?

The goods will be deliveried wthin 15 days after recepit of the deposit .

Products Photos

- Q: What are the allowable quantity differences in printed packaging materials?

- Printing, printing, usually three printing on a flat surface of a substrate. Screen printing can not only be printed on a flat surface, but also printed on a surface, and the spherical surface of the substrate is convex. On the other hand, screen printing is not only printed on hard objects, but also can be printed in a soft material without substrate limitations. In addition, screen printing, in addition to direct printing, can also be used according to the needs of indirect printing process, which is to use silk screen printing in gelatin or silica gel version, and then transferred to the substrate. Therefore, we can say screen printing is adaptable and wide range of applications. Strong, rich, textured layer thickness

- Q: What's the printing process for PC material? Is the print content on PC or other surfaces?

- Roll material, screen printing or rotary printing (relatively few, only for thickness below 0.125MM), printing the same as above.

- Q: Carton printing process and materials

- Single-sided corrugated production line adopts plastic gravure printing process composite paper carton packaging, paper printing also need to be completed if the light coating film, and large volume production, can be printed on the paper, and the way for gravure printing gravure printing on plastic film, and with white plastic film and paper and then the first printed composite, and then complete the box according to the conventional carton forming process.The process is characterized by:(1) the cost of making cartons is low. When the production batch is large, the printing cost and the material cost of the facial tissue can be greatly reduced by the process. Because the paper does not need to be printed, the uncoated white board paper can be used so as to greatly reduce the cost of the facial tissue.(2) beautifully printed. Because the plastic gravure printing is adopted, the printing effect can be compared with the offset printing effect. The process requires special attention. In the process of printing, it is necessary to take full account of the plastic film size changes and deformation; otherwise, the carton paper will be inconsistent with the lower paperboard.

- Q: What are the materials used in screen printing?

- Specifically, screen printing is mainly used in the following aspects: the art printing paper printing: advertising, jhenuk, calendar, lantern paper etc..Trademarks, printing, transfer printing, packaging, printing, building materials printing - wallpaper, etc. plastic printing plastic film - ethylene toys, bags, plastic bags and so on.Plastic plate -- false metal composite material and various labelsManufacturing parts - instruments.Wooden products printingHandicrafts - lacquerware, wooden arts and crafts, toys.Processing semi manufactured goods - sporting goods, boards, ceilings, road signs, signboards, fake metal wrenches, billboards, etc..Printing of metal productsMetal barrel, metal ware, metal product.Printing of glass and ceramic productsGlass -- mirrors, glass plates, cups, bottles, etc.Ceramic ware, arts and crafts.The label text plate, dial, shaped articles.The printed circuit boardPrinted circuit board, board for civil or industrial use, thick film integrated circuit board.The printing and dyeing cloth, printing and dyeing, flags, towels, handkerchiefs, shirts, vests, knitted fabrics etc.. 'Other printing - pockets, shoes, numbers, cloth, bags, backpacks, bags, schoolbags, etc..

Send your message to us

1220*2440*18mm Film Faced Plywood for Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches