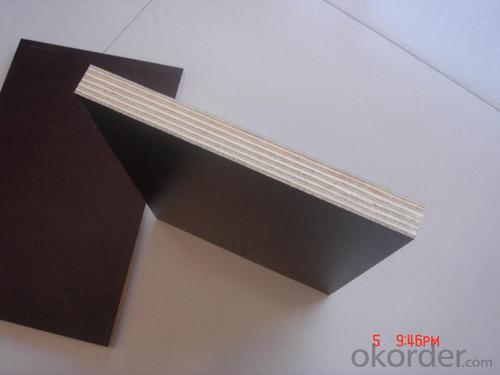

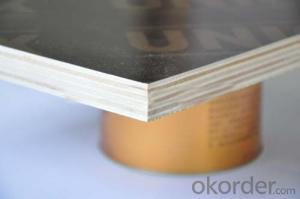

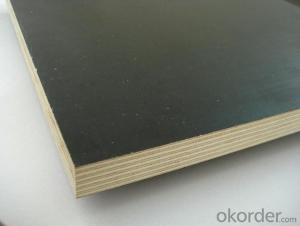

Black Film Faced Plywood Waterproof Plywood Prices for Formwork

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

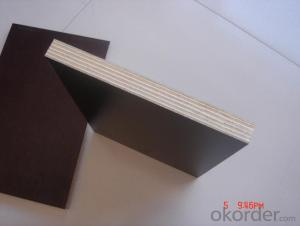

Item Name:Film Faced Plywood/Shuttering Plywood

Size:1220x1440mm,1250x2500mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,other thickness as requested

Description

| Product Name | Film Faced Plywood, Marine plywood |

| Place of origin | Shandong,China |

| Size | 610*2440mm,1220*2440mm,1250*2500mm |

| Thickness | 2mm to 25mm or as agreed |

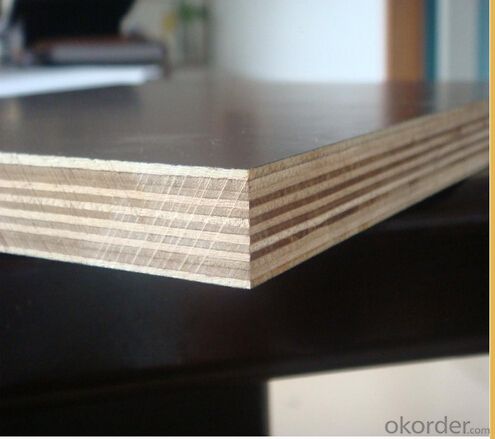

| Core | Poplar, Hardwood, Birch, Combi or as you agreed |

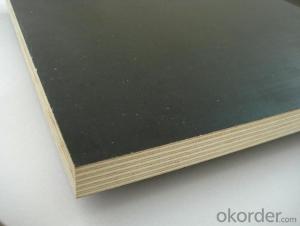

| Face/Back | Black, Brown, With LOGO, Anti-slip film etc. |

| Glue | MR, Melamine, WBP, Phenolic |

| Grade | BB/BB, BB/CC, CC/CC, CC/DD,DD/EE, etc. |

| Moisture | 10%-12% |

| Joint way | Overlap joint, end joint, scraf joint, finger joint |

| Certifications | American CARB, CE, FSC |

| Usage | Construction, Formwork, Waterproof materials |

| Min Order | 22.5 CBM/20GP, 54 CBM/40HQ |

| Delivery time | Within 15 days after receipt of deposit or original L/C. |

| Payment terms | TT, L/C at sight |

| Supply ability | 10000 cubic meters/month |

Features

1) Good Raw Materials and High quality

2) More repeated using times

3) Good packing and fast shipment

4) Delivery the right products according to different level of requirement

5) High performance/price ratio

FAQ

1.What's your company property ?

More than 10 factories to meet your various needs.

2.Free samples ?

Samples are free. As for the cost of courier , we will give back to you in the payment of the trial order .

3.What's your delivery time ?

The goods will be deliveried wthin 15 days after recepit of the deposit .

Products Photos

- Q: What are the allowable quantity differences in printed packaging materials?

- The ink thickness, three-dimensional sense of common offset and letterpress 5 microns to about 12 microns in gravure printing, flexo printing ink layer (aniline) is 10 microns thick, and the wire net printing ink thickness than the ink layer thickness is generally up to about 30 microns. Thick screen printing special printed circuit board, ink film thickness of up to 1000 microns. Foam ink printing Braille, foaming layer thickness of up to 300 microns. Screen printing ink layer thickness, printing texture rich, three-dimensional feeling strong, this is other printing methods can not match. Screen printing can not only print in monochrome, but also capture and screen color printing.

- Q: What's the printing process for PC material? Is the print content on PC or other surfaces?

- As a screen printing material, semi automatic screen printing machine for printing or anti India, in particular circumstances, is usually anti India, India will.

- Q: Carton printing process and materials

- Art paper gravure composite carton process, when the production of large quantities, without film, and requires good printing effect, low cost, you can use this process. This process is to use paper gravure printing machine printing thin coated paper, and then the printed coated paper and ordinary slag paper board or cardboard composite as a whole, carton paper, and then mounted on the carton forming normal.The process is characterized by:(1) the cost of making cartons is low. The main reason for the cost reduction is that the white board is changed into low weight coated paper, which is combined with cheap carton paper to reduce material cost.(2) beautifully printed. The gravure printing effect of paper is very exquisite.(3) gravure printing process is more complicated, and the cost is high, it is not suitable for printing, often revised carton products.(4) the operation and control methods of the printing process, such as paper compounding and box making, should be carefully explored and continuously accumulated and reasonably implemented. Otherwise, the waste rate will be easily increased.

- Q: What are the materials used in screen printing?

- Divided into printed screen and printed material, screen according to different processes are divided into water-based and solvent based, printed material according to different substrate is divided into ink and ink

Send your message to us

Black Film Faced Plywood Waterproof Plywood Prices for Formwork

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords