Anderson Plywood Sales - Black Anti-Slip Film Faced Plywood Formwork

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1026 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

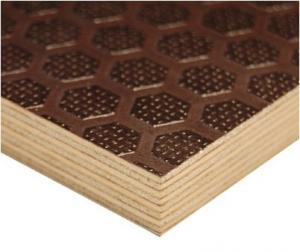

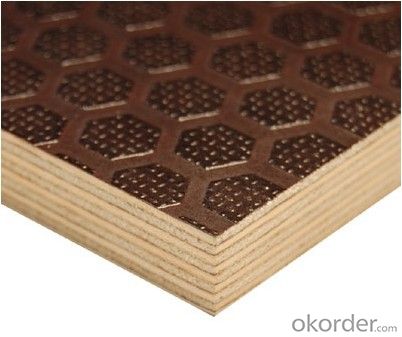

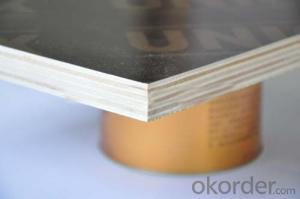

General Information of Black Anti-slip Film Faced Plywood

1.Size(mm): 1220x2440; 1250x2500 Thickness(mm):18; 15; 12; 20; 21

2.Glue: MR, melamine, phenolic, WBP Core: poplar, combi, hardwood, birch

3.Film: black film or as requested Color: black

4.Application :Construction material used for concrete forming mouldings.

5.Standard ISO9001

Packaging & Delivery

1.Packaging Detail: loosing package,pallets package,all can according to customers'requirements

2.Delivery Detail: delivery within 10 days after get the deposit

Specifications of Brown Film Faced Plywood

1.Usage:Decoration,Furniture,Construction.

2.Package:Inter packing:0.2mm plastic bag. Outer packing:Pallets are coverd with plywood or carton

3.Min order 1*20FCL or 23 cubic meter

4.Payment terms:L/C at sight,T/T 30% as deposit ,D/P.

5.Supply ability:6000 Cubic meter/month or 8000 pcs/day.

6.Main marke:Indonesia Malaysia India,Thariland,Middle East,Europe,Africa.

Advantage of Brown Film Faced Plywood

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q: Plywood in the material defects?

- resin leakage (resin) resin streak trees after the local injury, the resin gathered in a large number of them and through the surrounding wood and the formation of color than the surrounding normal wood deep

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- the minimum number of layers of each nominal thickness to comply with the relevant provisions.

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- Fibreboard: According to bulk density is divided into hard fiber board, semi-rigid fiberboard and soft fiber board 3 kinds. Hard fiber board is mainly used for the ceiling,

- Q: How do I determine if plywood contains formaldehyde?

- because it is often hidden behind the wood epidermis and must be carefully viewed, usually in seams and drills Of the place can be seen clues

- Q: What is a joinery board?

- Blockboard thickness specifications for the 16,19,22,25 mm quality grade is divided into one, two, three three levels

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

- Q: Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Plywood should be shipped with the factory quality inspection department of product quality certification, specify the type of plywood, specifications, grade, bonding strength and moisture content.

- Q: For the plywood environmental advice?

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: Does plywood contain formaldehyde?

- 12 cm plywood is usually 3-4 layers of natural wood chips "glue" together, each layer of double-sided roller plastic hot forming, the whole board about 3 kg of glue

Send your message to us

Anderson Plywood Sales - Black Anti-Slip Film Faced Plywood Formwork

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1026 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords