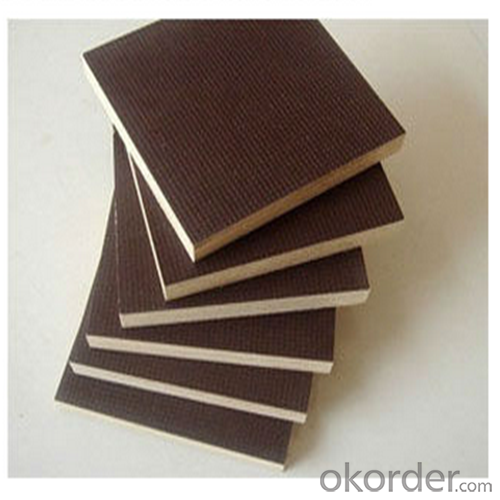

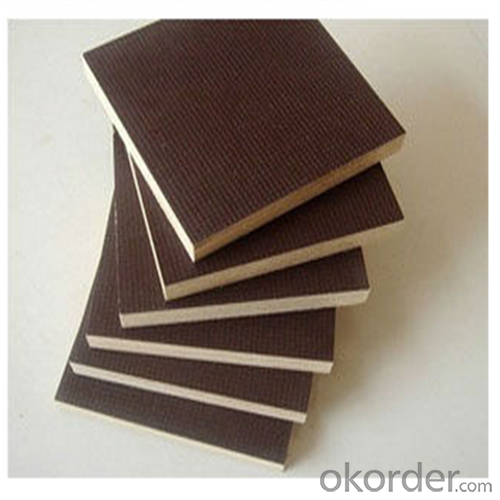

Poplar and Combi Material Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description:

Place of origin: Shandong China

Face&back: Okoume, Bintangor, Pencil Cedar, Keruing, Poplar, Birch, Pine, Maple, Hardwood, Ash, Oak and as your requested

Core: Poplar, Hardwood, Hardwood, Combi, Birch, eucalypts, as your requirement.

Size: 1220*2440/1250*2500mm and as your requirement

Thickness: 2mm to 30mm and as for your requirement

1/8 inch(2.7-3.6mm)

1/4 inch(6-6.5mm)

1/2 inch(12-12.7mm)

5/8 inch(15-16mm)

3/4 inch(18-19mm)

Thickness tolerance: 2-6mm: +/-0.2mm; 6-30mm: +/-0.3mm

Grade: BB/BB, BB/CC, CC/CC, CC/DD,DD/EE, etc.

Glue: MR,E1,E2,Melamine,WBP Phenolic

Moisture: 10%-15%

Joint way: Overlap joint, end joint, scraf joint, finger joint

Strength: High bending strength Strong nail holding

Quantity: 8 pallets/20ft,16 pallets/40ft,18 pallets/40HQ

Usage: construction, Furniture, decoration, packing.

Certificate: ISO9001: 2000; CE; CARB

Main market: Middle East, South Asia, South America, Africa

Shipment & payment:

MOQ: One container

Port: Qingdao Port, China

Packing details:

Inner packing: 0.2mm thick plastic bag

Outer packing: pallets covered with plywood/carton, then steel taped for strength

Delivery time: 2 weeks after your deposit

Payment: T/T, 30% deposit, the balance against the copy of B/L, L/C at sight.

Advantage:

Capacity: 6000 CBM per month

Can supply samples

High quality and competitive price

Over 30 years’ experiences in export

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Color steel sandwich panels are prefabricated or on-site production processing

- This is based on the specifications you want to color steel sandwich panels to customize, and some factories if you just need the specifications, then there may be spot Oh

- Q: OKorder Wang Teng color steel production and sales of a variety of color steel plate, Caigang tiles, Caigang rock wool sandwich panels, Caigang polyurethane sandwich panels, Caigang foam sandwich panels, Caigang extruded sandwich panels, color Steel paper honeycomb sandwich panels, galvanized sheet, floor board, Caigang sandwich panels, C steel, color steel activities, and other products.

- Energy-saving insulation: thermal insulation superior performance, the same thickness of the insulation effect is 2 times the EPS board. ? Flame retardant: The product has passed the "National Fixed Fire Extinguishing System and Refractory Component Quality Supervision Center", the combustion level to GB8624 B2 level standards. ? Sound insulation: sound absorption is good, on the rain, hail and other impact caused by the sound has a subtractive effect. ? Waterproof rust: a large span, fast drainage, waterproof effect is good; screw hidden, easy to rust, to extend the useful life of the plate. ? Beautiful economy: beautiful appearance, rich colors; reduce material loss, save construction time and project costs. ? Construction of fast: polyurethane sheet is a highly controlled plant in the factory environment, the quality of production, quality and stability; construction fast, the application has more than 35 years.

- Q: Sandwich panel sandwich panel characteristics

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. Sandboard is a common product in the current building materials, not only can a very good flame retardant and environmentally friendly sandwich board English name: laminboard sandwich panel products are made of two layers of metal panels (or other material panels) and Directly in the middle of the panel foam, mature molding of the polymer core insulation composition. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. [1] The formation of the outer steel plate takes full account of the structural and strength requirements, and take into account the aesthetic, the inner layer of the formation of flat to meet the needs.

- Q: Steel structure plant color steel sandwich panel roof design fire resistance 0.5H, need to apply fire retardant paint

- Need, the fire limit is half an hour, need to apply fire retardant coating.

- Q: Is polystyrene sandwich board flammable?

- In general, the benzene board is flammable, but there is a flame retardant type, is the type of self-extinguishing. Usually used as building materials. The other is basically flammable.

- Q: What are the thickness of the color steel sandwich board? Color steel sandwich panels: two layers of steel thickness of 0.6mm, the middle folder a layer of foam, a total thickness of several specifications?

- Color steel sandwich panel thickness generally have the following: 25mm 50mm 75mm 100mm 150mm 200mm which after the two kinds of thickness is generally used for cold storage. You said the foam (EPS) density of the points, generally: 4g 6g 8g 10g, Can be purchased according to their own needs!

- Q: Color steel rock wool sandwich board 50mm per square meter how much money

- The price by region, quality and demand to go, Tianjin is rock wool board manufacturers more cities, a single rock wool board, then many can do 40 or so per square meter

- Q: Color steel sandwich board where the best quality?

- To see where you are, too far away from the good cost is also high, the best distance from the nearest, I was Xuzhou people, I think before the company in the Pepsi Steel made Bo Sige plate is very good,

- Q: Rock wool sandwich board standards which

- Rock wool core material: the use of density of 120kg / m? rock block staggered laying, the fiber perpendicular to the sandwich plate on the upper and lower surfaces, and close contact to enrich the sandwich panel of the entire vertical and horizontal. The combination of rock wool and rock wool and the upper and lower steel plates through the high-strength foaming agent to form a whole, sophisticated production process to ensure that the high-density rockwool insulation and metal plate between the inner wall can produce poles Strong adhesion, so that the rock wool sandwich panel has a very good stiffness.

- Q: How to use the sandwich board to the concrete square column into a cylindrical and finishes are made of aluminum-plastic package, it is best to have pictures or drawings

- With a sandwich made of a semi-circular in the bottom of the column, the top and the middle of every 500 or so, with expansion bolts wooden side of the board will be fixed on the column, with a sandwich panel saw a narrow wood, Into a round wooden column of the pillars, and then stick to the aluminum plate.

Send your message to us

Poplar and Combi Material Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords