Poplar and Hardwood Core Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

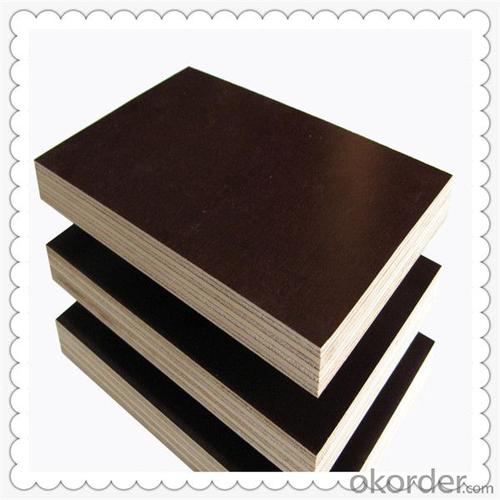

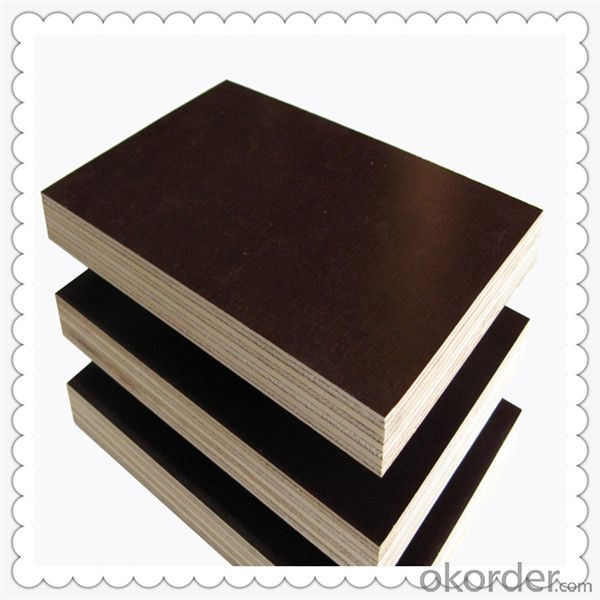

Poplar and Hardwood Core Film Faced Plywood

Product Description:

· Type: Film Faced Plywood

· Material: Wood

· Wood Style: Panel

· Panel Type: Plywood

· Use: outdoor

· Place of Origin: China (Mainland)

· Model Number: 1220x2440mm

· Main Material: Poplar

· Formaldehyde Emission Standards: E2

· Plywood Type: Veneer Boards

· Veneer Board Surface Finishing: Double-Sided Decoration

Packaging & Delivery:

1. Packaging Details: inner packing:0.20mm plastic bag; outer packing: pallets are covered with plywood or carton and then steel for strength

2. Delivery Detail: within 15 days after receiving the deposit

Product Specification:

Detailed Product Description | ||

Features | Face/back | melamine /veneer/pvc/hpl/ev (As you required) |

Glue | E1 or E2 ... (As you please) | |

Size | 1220*2440mm or 1830*2440mm | |

Thickness | 2.0mm~35mm | |

Core | poplar, combi etc. | |

Moisture | normal, moisture-proof, water-proof, eco-friendly | |

Payment & Shipping | MOQ | 1*20' container (negotiable) |

Port | Qingdao | |

Packing details | Inter packing: 0.20mm plastic bag Outer packing: pallets are covered with plywood or carton and then steel for strength | |

Delivery time | Within 15~20 days after 30% deposit or L/C | |

Payment terms | L/C,T/T | |

Supply ability | 50*40' HQ per Month | |

Advantages | Guarantee of 2 years | |

Competitive price | ||

ECO- friendly—— E1 grade, CARB P2 certificated | ||

High quality and excellent workmanship | ||

Company Info:

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

As of the end of 2000, CNBM has 492 member companies under management around the world, of which 5 were A-share listed holding companies and 2 were H-share listed. CNBM has total assets exceeded RMB 110 billion, and more than 100,000 employees.

CNBM is the largest comprehensive building material industrial group in China that integrates scientific research, manufacturing and logistics into one entity.

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Activities of the sandwich board, the middle of the middle of the kind of foam, a square meter how much money? And how much is that one window? Is it aluminum? How much is the door? Fujian Nanping where cheaper, I was Shaowu's.

- Board 50-100 yuan / m range mainly depends on how thick you use thick iron insulation layer Plastic doors and windows 200-300 yuan / square meter

- Q: How do you keep the shower and the regulating valve on the foam sandwich plate? Please enlighten me

- You need to use the screws to be fixed, even in the surface of the fixed are not used to wear screws to get better! "Wear" means, is to wear sandwich panels, with a screw through the sandwich panel and the other side of the sandwich panel fixed.

- Q: What are the sandwich panels used in steel roofs? How much is the price?

- There are two kinds of steel panels used in steel roofs, one is called sandwich panels, that is, the factory has been the roof of the inner and outer color plate and the middle of the insulation layer composite; the other is called composite board , That is, the roof of the site at the site will be inside and outside the color plate and the middle of the insulation layer installed together. The advantage of the sandwich panel is because the factory has been compounded, so the site is quick and easy to install; the shortcomings are limited by the transport, the length is generally within 12 meters, the length of the slope is greater than the roof of the hidden water leakage. Because of its different insulation materials, one for the polystyrene sandwich panels, commonly known as foam board, the other for the polyurethane sandwich panels. Specifications are generally 50mm, 75mm, 100mm thick, the main use of the South 50mm thick board, the price according to the origin of color plate inside and outside the different, different thickness will be a difference to conventional 50mm thick, inside and outside the color plate for the OKorder Baosteel 0.5mm board For example, the unit price of about 65 yuan / m2, the land prices will be different Above the thickness of the board for each additional 15 yuan / m2. The advantages of composite panels due to the production in the field compound, you can ensure that the slope of a long slope, there is no leakage of hidden dangers; the disadvantage is that the installation of a little trouble. Thickness and price of the same as above

- Q: Color steel rock wool sandwich board 50mm per square meter how much money

- The price by region, quality and demand to go, Tianjin is rock wool board manufacturers more cities, a single rock wool board, then many can do 40 or so per square meter

- Q: Who knows the standard of color steel composite panels which? No matter what kind of material sandwich layer, please know the knowledge of this person told me.

- 1. Light weight: 10-14 kg / square meter, equivalent to 1/30 of the brick wall. 2. Thermal insulation: core thermal conductivity: λ <= 0.041w / mk. 3. High strength: can be used for smallpox envelope structure bearing, bending compression; general housing without beams and columns. 4. Bright color: no surface decoration, color galvanized steel coating to maintain a period of 10-15 years. 5. Flexible installation: the construction period can be reduced by more than 40%. 6. Oxygen index: (OI) 32.0.

- Q: What are the varieties of foam sandwich panels? what is the price?

- Insulation and insulation The composite board commonly used insulation materials are: rock wool, glass fiber cotton, polystyrene, polyurethane, thermal conductivity is low, with good insulation effect. High strength with high strength steel as the substrate (tensile strength of 5600kg / cm) coupled with the most advanced design and roll forming, with excellent structural characteristics.

- Q: With a foam sandwich board made a 72 flat house, the cheapest how much money

- It depends on how high your house, the color plate is calculated by the board area, calculate the material about 90 or so per square

- Q: Can the color steel sandwich panels be properly bent?

- Color steel sandwich panels can not be bent, because the color steel sandwich panels have a certain thickness, bending shear stress will make the core and color steel surface separation, loss of color steel sandwich board carrying capacity, change is very soft. If you need special (curved) Caigang sandwich panels, can be customized to the factory processing, absolutely can not take their own flat bending.

- Q: We are the construction unit to the scene into the decoration with the sandwich panels and fire retardant coating supervision requirements were re-test and then also use a good brush-resistant paint sandwich panels to do re-examination Will this want to detect what the purpose of what is the detection of the project. Good people to help answer Thank you

- Testing items, the general requirements in the relevant norms, if there is no required material, you can not do the retest.

- Q: What is the name of the board?

- Hello, the common is polystyrene sandwich panels (EPS sandwich panels), commonly known as foam sandwich panels, the middle is the bubble, both sides of the steel plate, when pressed, the machine will have a brush brush glue, two glue in a short time Will quickly respond, and a certain amount of penetration into the bubble gap, to reach a solid role. (EPS can be understood as the availability of polystyrene, with the addition of flame retardants, without the addition of flame retardants. Another foam bulk density that density will also affect the cost of the entire sandwich panel, the two sides of the color coated roll Steel plate thickness of the impact of the largest price, followed by flame retardant or non-flame retardant, and then the foam bulk density) Other common rock wool sandwich panels, PU (polyurethane) sandwich panels, which are basically non-flammable rock wool, polyurethane prices are too high, very few people use. Some manufacturers may already be able to produce XPS like extruded foam plus the board. For a long time did not write this, when the review, and hope to help the landlord ~

Send your message to us

Poplar and Hardwood Core Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords