Galvanized Corrugated steel Plate for Roofing Type Galvanized steel Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

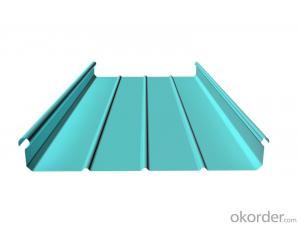

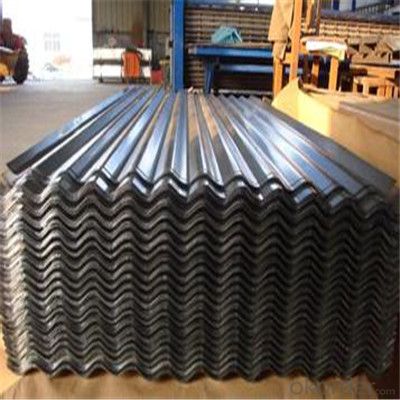

Description of Corrugated Iron Sheet:

The gloss can changeable by Customers' Request.we can also do some High gloss, with some sparkling granule in it.

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Residential - Row Houses, Bung alows, etc.

Commercial - Shopping Centers, Resorts, Hotels, etc.

Industrial - Porches, sloped roof slabs, etc.

Institutional - Colleges, School Building, etc.

Agriculture - Farm Houses, etc.

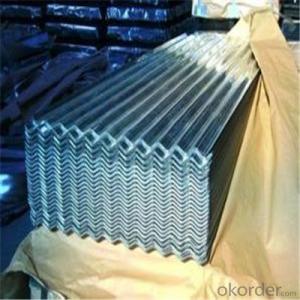

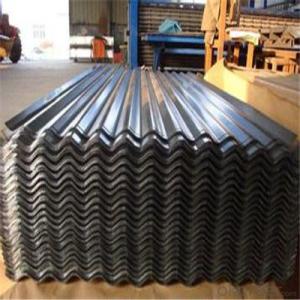

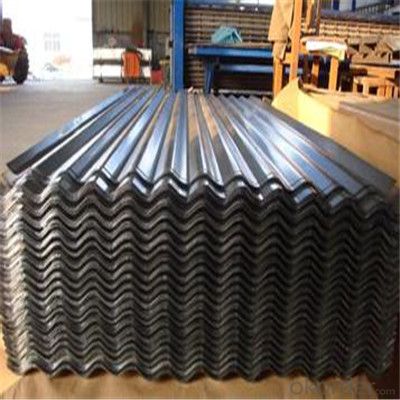

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Can steel sheets be formed into curved shapes?

- Indeed, curved shapes can be achieved with steel sheets by means of a technique referred to as cold forming or bending. Without the need for heating, cold forming entails exerting pressure upon the steel sheet to reshape it. Roll forming, press braking, and stamping are among the different methods employed to accomplish this process. The malleability of steel enables it to be effortlessly molded into curves, thereby rendering it a versatile substance suitable for a wide range of applications in sectors like construction, automotive, and aerospace.

- Q: What is the average weight of a steel sheet per square foot?

- The weight of a steel sheet per square foot can change based on its thickness and the type of steel employed. Nevertheless, a typical weight range for a steel sheet per square foot falls between 40 and 70 pounds. It is crucial to understand that this is a rough approximation, and the actual weight may deviate due to specific factors like alloy composition and the manufacturing process.

- Q: How do steel sheets perform in UV resistance?

- Steel sheets do not have inherent UV resistance. However, their UV resistance can be enhanced by applying protective coatings or finishes such as paint or galvanization.

- Q: What is the average lifespan of painted steel sheets?

- Painted steel sheets can have varying lifespans depending on factors such as paint quality, usage environment, and maintenance levels. Generally, their lifespan ranges from 15 to 25 years. This estimate is based on proper installation, regular inspections for damage or corrosion, and necessary touch-up or maintenance work. It is worth noting that exposure to severe weather, chemicals, and physical damage can significantly affect the lifespan of painted steel sheets. To go beyond the average range, regular maintenance and appropriate care are essential.

- Q: Can steel sheets be used for food processing equipment?

- Yes, steel sheets can be used for food processing equipment. Stainless steel is a popular choice for food processing equipment due to its durability, corrosion resistance, and ease of cleaning. It is non-reactive with food and does not impart any unwanted flavors or odors. Steel sheets can be formed into various shapes and sizes, making them suitable for different types of food processing equipment such as mixers, conveyors, tanks, and cutting blades. Additionally, stainless steel is also resistant to high temperatures, making it ideal for applications that involve heat. Overall, steel sheets are a reliable and hygienic material choice for food processing equipment.

- Q: Are steel sheets suitable for food processing applications?

- Yes, steel sheets are suitable for food processing applications. Steel sheets are known for their durability, corrosion resistance, and hygiene properties, making them ideal for food processing environments where cleanliness and safety are crucial. Additionally, steel sheets can withstand high temperatures, making them suitable for various food processing operations such as cooking, baking, and freezing.

- Q: Is the steel plate 1.5 meters wide and 2 meters wide at the same price? .

- The steel plate price is generally not the width, they only according to the different material steel plate, gives you to quote the unit price.

- Q: How do steel sheets compare to stainless steel sheets in terms of corrosion resistance?

- Steel sheets and stainless steel sheets differ significantly in terms of corrosion resistance. While steel sheets are prone to corrosion due to their high carbon content, stainless steel sheets are specifically designed to resist corrosion. This is achieved by adding chromium to the alloy, which forms a protective oxide layer on the surface, preventing rust and corrosion. Therefore, stainless steel sheets offer superior corrosion resistance compared to regular steel sheets.

- Q: Is color steel plate the same as color steel tile?

- Color steel plate color steel plate refers to color coated steel plate, color coated steel plate is a kind of organic coated steel plate.Color steel plate coating is cold-rolled steel sheet, galvanized steel sheet, after surface chemical treatment, coating (roll coating) or composite organic film (PVC film, etc.), and then baked, cured and made of products.

- Q: Can steel sheets be used for architectural purposes?

- Yes, steel sheets can be used for architectural purposes. Steel sheets are versatile and widely used in architecture due to their strength, durability, and flexibility. They can be used for various architectural elements such as roofs, walls, cladding, and structural components. Additionally, steel sheets offer a wide range of design possibilities and can be easily customized to meet specific architectural requirements.

Send your message to us

Galvanized Corrugated steel Plate for Roofing Type Galvanized steel Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords