Galvanized Corrugated steel Plate for Roofing/Galvanized steel Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

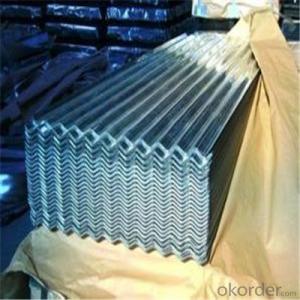

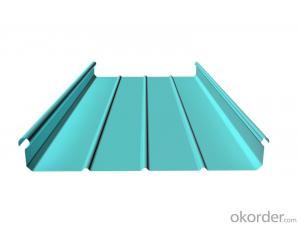

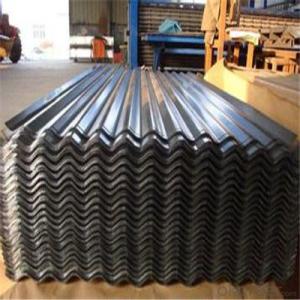

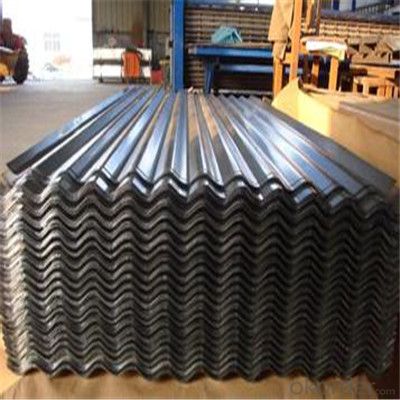

Description of Corrugated Iron Sheet:

most of corrugated board are cold-rolled sheet steel,after galvanized zinc or aluminium, paint layer to suppress into finished products and the width is generally 600-1200mm, dedicated to building roof, walls retaining plate.

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

wall panel and ceiling board, etc.At the same time of using corrugated plate, using color steel plate do some wall decoration to make the building’s decoration effect looks new and unique.

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: How do steel sheets compare to other materials, such as aluminum or copper?

- Steel sheets have several advantages over other materials such as aluminum or copper. Steel is generally stronger and more durable, making it suitable for applications that require high strength and resistance to wear and tear. It is also more cost-effective and readily available, making it a popular choice in various industries. While aluminum and copper may offer better conductivity or corrosion resistance, steel sheets often provide a good balance of properties, making them a versatile and widely used material.

- Q: What are the different grades of steel used for manufacturing sheets?

- There are several different grades of steel used for manufacturing sheets, each with specific properties and applications. Some of the commonly used grades include: 1. Mild Steel (also known as low carbon steel): This is the most widely used grade of steel for manufacturing sheets. It has a low carbon content, making it easy to work with and relatively inexpensive. Mild steel sheets are used in a variety of applications, such as construction, automotive manufacturing, and general fabrication. 2. High-strength Low-alloy (HSLA) Steel: This grade of steel provides higher strength and improved corrosion resistance compared to mild steel. HSLA steel sheets are commonly used in heavy machinery, transportation equipment, and structural applications where strength is critical. 3. Galvanized Steel: Galvanized steel sheets are coated with a layer of zinc, which provides excellent corrosion resistance. These sheets are commonly used in outdoor applications, such as roofing, siding, and automotive parts. 4. Stainless Steel: Stainless steel sheets are highly resistant to corrosion and staining, making them suitable for a wide range of applications. They are commonly used in food processing equipment, medical devices, and architectural components. 5. Tool Steel: Tool steel sheets are specifically designed to have high hardness, wear resistance, and toughness. They are used for manufacturing cutting tools, dies, and molds. These are just a few examples of the different grades of steel used for manufacturing sheets. The choice of grade depends on the specific requirements of the application, such as strength, corrosion resistance, and cost.

- Q: Can steel sheets be used for transportation applications?

- Transportation applications can indeed make use of steel sheets. Steel has gained immense popularity in the automotive and aerospace sectors owing to its exceptional strength, durability, and resistance to corrosion. Chassis, body panels, doors, and structural parts in various transportation components are often constructed using steel sheets. These sheets offer remarkable structural integrity and can endure substantial loads, making them ideal for vehicles and aircraft. Moreover, steel sheets can be effortlessly shaped, welded, and machined, enabling customization and efficient manufacturing procedures.

- Q: Are steel sheets affected by UV radiation?

- Yes, steel sheets can be affected by UV radiation. Over time, prolonged exposure to UV radiation can cause fading, discoloration, and even degradation of the protective coating on the steel sheets, leading to potential corrosion and reduced structural integrity.

- Q: Are steel sheets suitable for fire-resistant applications?

- Steel sheets are indeed appropriate for applications that require resistance to fire. Steel has gained a reputation for its exceptional fire resistance properties, primarily because of its high melting point and its reluctance to ignite or facilitate the spread of fire. Steel sheets can be employed in an array of fire-resistant applications, including fire doors, fire-rated walls, and fireproof enclosures. Moreover, steel sheets can be combined with other fire-resistant materials, like fire-resistant coatings or insulation, to augment their fire resistance even further. In general, steel sheets are a dependable option for fire-resistant applications owing to their robustness, potency, and capacity to endure high temperatures.

- Q: Are steel sheets suitable for data center infrastructure?

- Indeed, data center infrastructure can rely on steel sheets. The utilization of steel sheets in the establishment of data centers is prevalent because of their exceptional robustness, longevity, and resistance to fire. Furthermore, they furnish essential support for the infrastructure, encompassing server racks, cabinets, and raised flooring systems. Not only do steel sheets safeguard data center equipment against potential dangers such as electromagnetic interference (EMI) and physical harm, but they can also be conveniently tailored and adapted to suit the precise demands of a data center. This adaptability renders them a favored option for constructing data center infrastructure.

- Q: Can steel sheets be used for decorative purposes?

- Yes, steel sheets can be used for decorative purposes. They can be shaped, cut, and finished in various ways to create unique and visually appealing designs. Steel sheets are often used in architecture, interior design, and artwork, adding a modern and industrial aesthetic to spaces.

- Q: What are the common tolerances for steel sheets?

- The common tolerances for steel sheets typically vary depending on the specific application and industry standards. However, some common tolerances for steel sheets include thickness variations, flatness, and width and length dimensions. These tolerances are often specified in accordance with recognized industry standards such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization).

- Q: What is AO steel plate?

- It is better to meet the anatomical angle and bone surface in steel plate and Futie professional medical professional operation, to fracture the bones to firm, stable and maximum support.

- Q: How do steel sheets handle chemical exposure?

- Steel sheets are highly resistant to chemical exposure due to their inherent corrosion resistance. The chemical composition and protective coatings on steel sheets make them capable of withstanding a wide range of chemical substances without significant degradation or damage.

Send your message to us

Galvanized Corrugated steel Plate for Roofing/Galvanized steel Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords