Galvanized Corrugated Iron Sheet for Roofing Type Galvanized Steel Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

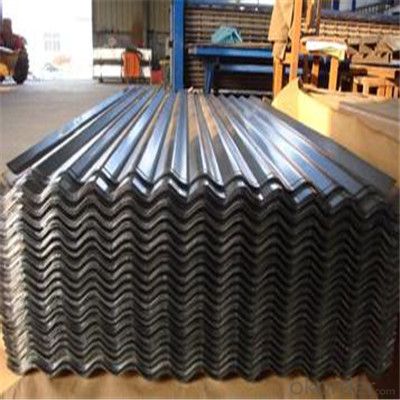

Description of Corrugated Iron Sheet:

Weight of each package: about 4.1mt

Width: 600mm-1250mmWidth tolerance:-0/+3mm

Depth of corrugated: from 23mm to 25mm

Pitch: from 57mm to 59mm

Length: less than 12m

Surface treatment: chromate, oil/unoil, bright finish, spangle

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

(1) Novel and beautiful modeling , rich luster, strong adornment sex, flexible in combination, can express different architectural styles;

(2) Light weight (6 ~ 10 kg/m squared) high strength (yield strength 250 ~ 550 mpa) fine skin stiffness,fine seismic performance of waterproofing agent;

(3) Factory product with high quality

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What is the thickness range for steel sheets?

- The thickness range for steel sheets can vary depending on the specific type and grade of steel, but it typically ranges from 0.4 millimeters to 6 millimeters or more.

- Q: Are the steel sheets heat-resistant?

- Indeed, steel sheets exhibit remarkable resistance to heat. Renowned for its elevated melting point, steel proves to be an apt substance for situations that entail exposure to extreme temperatures. It possesses the ability to endure heat without distorting or compromising its structural integrity. Nonetheless, the precise extent of this heat resistance may fluctuate contingent upon the distinct variety of steel and its composition. Certain steel alloys are intentionally formulated to possess an even greater resistance to heat, rendering them suitable for implementation in sectors like aerospace, automotive, and construction, where elevated temperature environments are prevalent.

- Q: How to choose welding method for welding different plate and thick steel plate?

- Plate groove, the groove thickness is less than or equal to the thickness of the sheet, the welding arc to a plate, the molten pool of molten iron melt sheet, the specific point of view of plate thickness difference, observe the molten pool adjust current, prevent sheet welding, double-sided welding when necessary.

- Q: How do steel sheets handle bending or flexing?

- Steel sheets are known for their excellent strength and rigidity, making them highly resistant to bending or flexing. The inherent properties of steel, such as its high tensile strength and stiffness, allow it to withstand substantial external forces without deforming. Steel sheets can handle bending or flexing to a certain extent without compromising their structural integrity, making them suitable for a wide range of applications. When steel sheets are subjected to bending or flexing forces, they undergo a process known as elastic deformation. This means that the steel will temporarily change shape under the applied load, but it will return to its original form once the load is removed. This elasticity is due to the crystalline structure of steel, which allows it to absorb and distribute the stress evenly throughout its structure. However, it is important to note that steel sheets do have a limit to their bending or flexing capabilities. Beyond a certain point, the applied load can cause the steel to undergo plastic deformation, which results in permanent changes to its shape. This can lead to the formation of cracks or fractures in the material. The maximum amount of bending or flexing that steel sheets can tolerate before experiencing plastic deformation is determined by factors such as the thickness of the sheet, the grade and type of steel used, and the specific application requirements. To enhance the flexibility of steel sheets, certain processes such as cold rolling or annealing can be employed. Cold rolling involves passing the steel sheet through rollers at ambient temperature, which not only increases its strength but also improves its ability to withstand bending or flexing forces. Annealing, on the other hand, involves heating the steel to a specific temperature and then cooling it slowly to relieve internal stresses, making it more ductile and less prone to cracking. In conclusion, steel sheets are highly capable of handling bending or flexing due to their inherent strength, rigidity, and elasticity. However, it is essential to consider the specific application requirements and the limitations of the steel sheet to ensure its performance and longevity.

- Q: Can steel sheets be used for storage tanks or containers?

- Yes, steel sheets can be used for storage tanks or containers. Steel is a durable and strong material that can withstand high pressure and is resistant to corrosion, making it suitable for storing various substances and materials.

- Q: Can steel sheets be used for automotive wheels?

- No, steel sheets are not typically used for automotive wheels. Wheels are usually made from aluminum alloy or magnesium alloy, as these materials provide better strength-to-weight ratio and improve the overall performance and fuel efficiency of the vehicle.

- Q: What is the difference between a painted and powder coated steel sheet?

- The main difference between a painted and powder coated steel sheet lies in the application process and the resulting finish. Painted steel sheets are typically coated with a liquid paint, which is applied using a variety of methods such as spraying, brushing, or dipping. This liquid paint contains pigments and binders that adhere to the steel surface and form a protective layer. The paint can be customized in terms of color, gloss, and texture, allowing for a wide range of design possibilities. However, painted surfaces may be prone to chipping, peeling, and fading over time, especially in harsh environments or with exposure to UV radiation. On the other hand, powder coated steel sheets are coated with a dry powder, which is electrostatically applied to the steel surface. The powder consists of a mixture of finely ground particles, including pigments, resins, and additives. Once applied, the steel sheet is heated, causing the powder particles to melt and fuse together, forming a durable and uniform coating. The result is a smooth, even finish that provides excellent resistance to chipping, scratching, and UV radiation. Powder coating also offers a wider range of color options and finishes compared to traditional liquid paint. In summary, while both painted and powder coated steel sheets provide a protective layer and aesthetic appeal, powder coating offers superior durability, resistance to damage, and a wider range of design possibilities.

- Q: Can steel sheets be used for noise barriers?

- Indeed, noise barriers can indeed utilize steel sheets. Steel, being a resilient and sturdy substance, can effectively hinder or diminish the propagation of sound waves. Its substantial density and mass aid in the absorption and reflection of sound, thereby impeding its passage through the barrier. It is possible to tailor and produce steel sheets specifically for the purpose of noise reduction, incorporating attributes like perforations or acoustic insulation materials to enhance their efficacy. Moreover, steel sheets can be treated with coatings or paint to bolster their resistance against adverse weather conditions and corrosion. In general, steel sheets present a feasible choice for the construction of noise barriers, particularly in locales with elevated levels of noise pollution.

- Q: How is the quality of steel sheets determined?

- The quality of steel sheets is determined by several factors and tests. One of the primary factors is the chemical composition of the steel, which includes the presence and percentage of various elements such as carbon, manganese, silicon, and alloying elements like chromium, nickel, and molybdenum. The specific composition affects the steel's strength, durability, and resistance to corrosion. Another important aspect is the mechanical properties of the steel, which are assessed through tests such as tensile strength, yield strength, elongation, hardness, and impact resistance. These tests help determine the steel's ability to withstand applied forces and deformation without failure. Surface quality is also crucial in determining the quality of steel sheets. The surface should be free from defects like cracks, scratches, pits, or any other irregularities that could affect the performance or appearance of the steel. Furthermore, the thickness and uniformity of the steel sheets are crucial factors. Thickness is measured using methods like ultrasonic gauges or micrometers to ensure compliance with the required specifications. Any deviations from the specified thickness can affect the structural integrity and performance of the steel sheets. Additionally, the steel sheets undergo various tests to assess their weldability, formability, and machinability, which determine their suitability for specific applications. These tests help evaluate the steel's behavior during fabrication processes like welding, bending, or machining. Overall, the quality of steel sheets is determined by a comprehensive evaluation of their chemical composition, mechanical properties, surface quality, thickness, and other specific performance characteristics. These assessments ensure that the steel sheets meet the required standards and are suitable for the intended applications.

- Q: Can steel sheets be used for manufacturing machinery or equipment?

- Yes, steel sheets can be used for manufacturing machinery or equipment. Steel sheets are commonly used in the manufacturing industry due to their strength, durability, and versatility. They can be shaped, cut, and formed into various components and structures required for machinery and equipment. Steel sheets provide structural support, withstand heavy loads, and offer resistance to wear, making them an ideal choice for manufacturing purposes.

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing Type Galvanized Steel Plain Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords