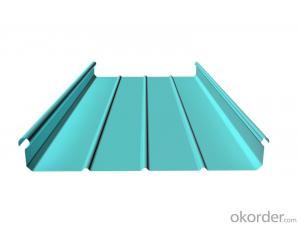

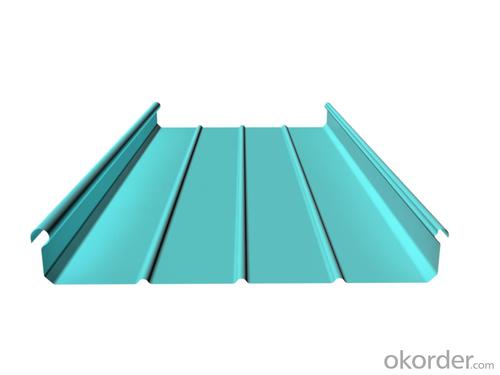

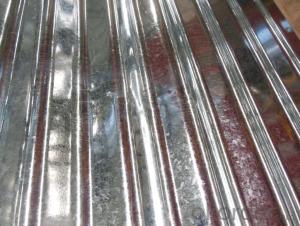

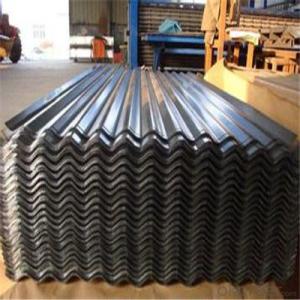

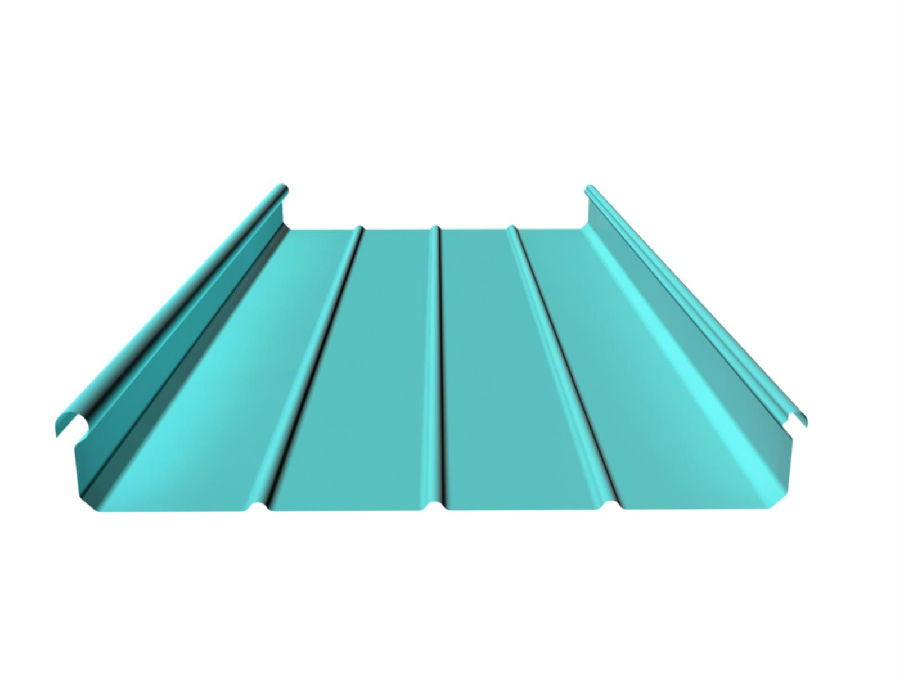

Galvanized Color steel Plate roofing Corrugated

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Color steel Plate roofing Corrugated Details

Standard: | AISI,ASTM,BS,DIN,GB | Grade: | Q235,Q345,Q195 |

Technique: | Cold Rolled | Color: | many color |

Thickness: | 0.8mm-4mm,0.3mm-1mm | Surface Treatment: | Coated |

Width: | 600mm-1250mm | Length: | as oer customer's requirement |

experience: | more tahn 8 years | Thickness tolerance: | as per standard |

Type: | Steel Plate |

Packaging & Delivery

Packaging Detail: | Standard Export Package |

Delivery Detail: | 15-30 working days after receive the deposit |

Galvanized Color steel Plate roofing Corrugated Specifications

Corrugated steel sheet

Prompt Delivery

Flexible Payment Terms

Market:Middle East,Asia

Galvanized Color steel Plate roofing Corrugated Services

Our samples can be offerd with sample charged and curier fee by buyer's side

we have full stock, and deivery in short time, many styles with your choices

Good quality+factory price +Quick pesponse +Relablie service, is what we are best trying with you.

All of the products produce by our professionl workman and we have our high-work- effect foreign trde team, you kan totally believe our service.

After you choose, we will count chepest shipping cost and make invoie to you.

Check quality again, and send out to you 1-2 working days after your payment.

Galvanized Color steel Plate roofing Corrugated Pictures

- Q: Can steel sheets be used for heat exchangers or boilers?

- Yes, steel sheets can be used for heat exchangers or boilers. Steel is a commonly used material for these applications due to its excellent thermal conductivity, high strength, and resistance to corrosion at high temperatures.

- Q: What are the different types of steel coatings for sheets?

- There are several different types of steel coatings for sheets, including galvanized, galvannealed, aluminized, and stainless steel coatings.

- Q: How are steel sheets stored and transported?

- Steel sheets are typically stored and transported in stacks or bundles, where they are secured using steel strapping or banding. These bundles are often stored in warehouses or outdoor storage yards, with appropriate spacing and support to prevent damage. When being transported, steel sheets are loaded onto trucks or shipping containers, ensuring they are properly secured and protected from external elements.

- Q: Can steel sheets be bent or formed?

- Yes, steel sheets can be bent or formed due to their malleability and ductility properties.

- Q: How can the steel plate of flat welding 10mm make its deformation smaller?

- High technical content is: two side groove, one side of the groove is deep, one side of the groove is shallow, the depth of difference is a seam, the two sides welding at the same time, pay attention to the deep groove of this face to be in the lead.Other ways to prevent the in-plane deformation of steel plate are: back welding, skip welding and so on.

- Q: What's the difference between a spray plate and a colored steel plate?

- Then the color, not the quality of the domestic coatings products, fully meet the demand, the high price of imported coating reduces the competitiveness of skin colour in the plastic film is still dependent on imports, lack of high-grade color coating thickness, functional, high strength, rich color coated plate. Therefore, the choice of color steel plate is relatively narrow, and basically are low-end products, but more convenient, you can buy directly!

- Q: What are the disadvantages of using steel sheets?

- Some potential disadvantages of using steel sheets are their susceptibility to corrosion, their relatively high cost compared to other materials, and their heavy weight, which can make installation and transportation more challenging. Additionally, steel sheets may require regular maintenance to prevent rust and may not be suitable for certain design aesthetics or applications where a lighter material is desired.

- Q: What is the average cost of steel sheets compared to fiberglass?

- The average cost of steel sheets is generally higher compared to fiberglass sheets.

- Q: What is the typical composition of stainless steel sheets?

- The primary constituents of stainless steel sheets are iron, chromium, and nickel, which are responsible for its distinct properties. The proportions of these three elements can vary depending on the specific grade of stainless steel being utilized. On average, stainless steel sheets typically contain approximately 10-30% chromium and 8-20% nickel. Moreover, small quantities of other elements like carbon, manganese, and molybdenum may be present to further augment the strength, corrosion resistance, and other desired characteristics of the stainless steel. The composition of stainless steel sheets is meticulously balanced to attain the desired amalgamation of durability, strength, and resistance to corrosion, which makes it a highly favored choice across industries such as construction, automotive, and manufacturing.

- Q: How do you cut steel sheets?

- Steel sheets can be cut through several methods, including using power tools such as plasma cutters, laser cutters, or shearing machines. These tools provide precise and efficient cuts by melting, burning, or shearing through the steel sheet. The choice of method often depends on the thickness and type of steel being cut, as well as the desired precision and speed.

Send your message to us

Galvanized Color steel Plate roofing Corrugated

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords