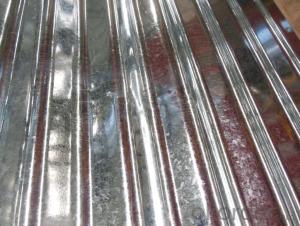

COLOR COATED GALVANIZED STEEL CORRUGATED SHEETS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

COLOR COATED GALVANIZED STEEL CORRUGATED SHEETS

THICKNESS:0.26mm

1.WIDTH:820mm (0/+5mm, AFTER CORRUGATION)

2.LENGTH:3000mm (0/+5mm), 5800mm (0/+5mm)

3.ZINC COATING:60g/m2

4.STANDARD:JIS G 3312, CGCC (SOFT QUALITY)

5.TOP COATING:5+15 MICRON(POLYESTER); BACK COATING:5-7 MICRON (EPOXY),LIGHT GREY

6.COLOR:AS PER RAL CARD

7.PACKAGE WEIGHT:3-3.5tons/BUNDLES

8.TOLERANCE: -/+5 % TOLERANCE WITH QTY AND AMOUNT (THICKNESS:-/+0.02mm; WIDTH:0/+5mm; ZINC COATING:-/+10g/m2; COATING MASS THICKNESS:-/+ 2 MICRON)

9.PAYMENT TERM:30% TT advance,70% against BL copy OR 100% LC AT SIGHT.

10.SHIPMENT: WITHIN 35 DAYS AFTER RECEIVING THE DEPOSIT.

11.DOUCUMENTS:COMMERCIAL INVOICE IN THREE ORIGINAL,PACKING LIST IN ONE ORIGINAL AND SPECIFICATION,CERTIFICATE OF ORIGIN.

- Q: What are the different types of surface patterns available for steel sheets?

- Steel sheets come in a variety of surface patterns, each with its own unique properties and appearances. Here are some of the most common patterns: 1. Smooth: Smooth steel sheets have a flat and even surface, without any visible patterns or textures. They are used when functionality is more important than aesthetics. 2. Diamond: Diamond pattern steel sheets have a raised diamond-shaped pattern, providing excellent slip resistance. They are suitable for areas where grip is important, such as flooring and stairs. 3. Checkered: Checkered steel sheets have a grid-like pattern with raised and recessed squares or rectangles. This pattern enhances slip resistance and is commonly used in industrial and transportation applications. 4. Embossed: Embossed steel sheets have a textured pattern pressed or rolled onto the surface. They can have designs like wood grain or geometric shapes, and are used in interior and architectural applications for their decorative and tactile qualities. 5. Perforated: Perforated steel sheets have evenly spaced holes or perforations, allowing for air, light, and sound to pass through. They are used in industries such as filtration and ventilation. 6. Brushed: Brushed steel sheets have a satin-like finish achieved by mechanically polishing the surface in one direction. This creates a sleek and modern appearance, commonly seen in architectural and decorative applications. 7. Rustic: Rustic steel sheets have a weathered or aged appearance, resembling rusted or patinated metal. This aesthetic is achieved through chemical treatments or specialized coatings, and is popular in architectural and interior design. These are just a few examples of the different surface patterns available for steel sheets. The choice of pattern depends on the desired functionality, aesthetics, and specific requirements of the application.

- Q: Are steel sheets suitable for automotive body panels?

- Yes, steel sheets are suitable for automotive body panels. They provide excellent strength, durability, and crash-resistance, making them a popular choice in the automotive industry. Additionally, steel sheets are cost-effective and easily customizable, making them an ideal material for automotive body panels.

- Q: What are the common thicknesses available for steel sheets?

- The common thicknesses available for steel sheets typically range from 0.5 mm to 25 mm, depending on the specific application and industry requirements.

- Q: Are the steel sheets perforated or solid?

- The steel sheets are perforated.

- Q: Are steel sheets suitable for playground equipment?

- Yes, steel sheets can be suitable for playground equipment. Steel is a durable and strong material that can withstand heavy use and various weather conditions. It can be used to create structures like climbing frames, slides, and swings, ensuring the safety and longevity of the playground equipment.

- Q: Can the steel sheets be used for storage racks or shelves?

- Yes, steel sheets can be used for storage racks or shelves as they provide durability, strength, and stability required for supporting heavy loads.

- Q: How do steel sheets compare to wood sheets?

- Steel sheets and wood sheets differ significantly in terms of strength, durability, and usage. To begin with, steel sheets are renowned for their remarkable strength and durability. They can endure heavy loads, extreme weather conditions, and possess high resistance to warping, rotting, and insect damage. Conversely, wood sheets are less sturdy and may succumb to moisture, termites, and decay if not adequately treated or maintained. Regarding versatility, steel sheets offer a wide array of applications. Their high tensile strength and structural stability make them commonly utilized in the construction, automotive, and manufacturing industries. Conversely, wood sheets are commonly employed in interior design, furniture production, and smaller-scale construction projects due to their natural aesthetic appeal and ease of manipulation. Furthermore, steel sheets are fire-resistant, making them a safer option compared to wood sheets, which are combustible and can contribute to the spread of fire. Steel sheets also boast a longer lifespan, necessitating less maintenance and replacement compared to wood sheets, which may require regular refinishing, sealing, or replacement due to wear and tear. Nevertheless, wood sheets possess their own advantages. They are generally more cost-effective than steel sheets, making them a popular choice for projects with budget constraints. Additionally, wood sheets have superior insulation properties, providing natural warmth and soundproofing qualities. Ultimately, the selection between steel sheets and wood sheets hinges on the specific project requirements, encompassing factors such as budget, desired aesthetics, structural needs, and environmental considerations.

- Q: Are the steel sheets suitable for automotive body repairs?

- Yes, steel sheets are commonly used in automotive body repairs due to their durability and strength, making them suitable for repairing damaged car bodies.

- Q: Can steel sheets be used in the construction industry?

- Yes, steel sheets can be commonly used in the construction industry. Steel sheets are highly versatile and have a wide range of applications in construction. They are used for various purposes, including roofing, wall cladding, flooring, and structural components such as beams, columns, and trusses. Steel sheets are preferred due to their high strength-to-weight ratio, durability, and resistance to corrosion. They can withstand heavy loads and provide stability and structural integrity to buildings. Additionally, steel sheets can be easily fabricated, allowing for customization and efficient construction processes. Overall, steel sheets are a popular choice in the construction industry due to their numerous advantages and suitability for various construction applications.

- Q: Are steel sheets resistant to corrosion?

- Yes, steel sheets are resistant to corrosion due to their high iron content, which forms a protective oxide layer on the surface, preventing rust and other forms of corrosion.

Send your message to us

COLOR COATED GALVANIZED STEEL CORRUGATED SHEETS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords