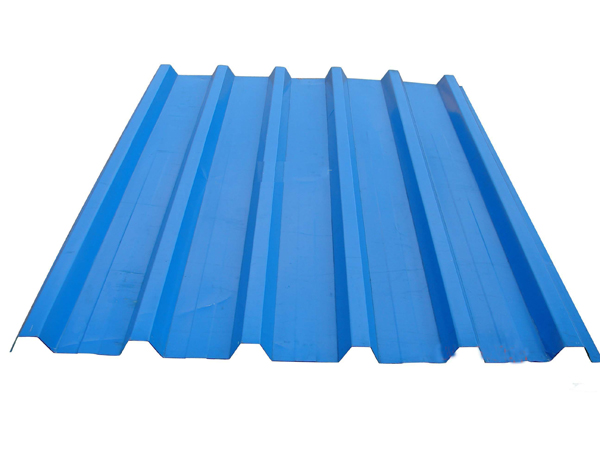

Corrugated Color Steel Sheet with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 180000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corrugated steel sheet

Corrugated steel sheet is a building material composed of sheets of hot-dip galvanised mild steel, cold-rolled to produce a linear corrugated pattern in them. The corrugations increase the bending strength of the sheet in the direction perpendicular to the corrugations, but not parallel to them. Normally each sheet is manufactured longer in its strong direction.

Characteristic

CGI is lightweight and easily transported. It was and still is widely used especially in rural and military buildings such as sheds and water tanks. Its unique properties were used in the development of countries like Australia from the 1840s, and it is still helping developing countries today.

Packaging & Delivery

Packaging Details:by plastic film

Delivery Detail:15days

Specifications

thickness:0.3mm-0.6mm

width:840mm

length:less 12m

color:red blue white grey

- Q:What is the typical yield strength of a steel sheet?

- The typical yield strength of a steel sheet can vary depending on the specific grade and thickness, but it is generally around 300 to 400 megapascals (MPa).

- Q:Can steel sheets be used for kitchen appliances?

- Yes, steel sheets can be used for kitchen appliances. Steel is a popular material choice for kitchen appliances due to its durability, strength, and resistance to corrosion. It is commonly used in the manufacturing of refrigerators, ovens, dishwashers, and other kitchen appliances. Steel sheets can be easily molded and fabricated into various shapes and sizes, making them suitable for different appliance designs. Additionally, steel is easy to clean, making it hygienic and ideal for kitchen environments.

- Q:Are steel sheets suitable for construction applications?

- Steel sheets are an ideal choice for construction applications due to their exceptional qualities. Renowned for their strength, durability, and versatility, steel is widely favored in the construction industry. Steel sheets find extensive use in various areas, including roofing, flooring, wall panels, structural frames, and cladding. They possess remarkable load-bearing capacity, enabling the construction of substantial and robust structures. Furthermore, steel sheets offer fire resistance, thereby enhancing the safety of buildings. Additionally, they are resilient against pests, rot, and corrosion, ensuring a prolonged lifespan for constructions. Moreover, steel sheets can be effortlessly fabricated and tailored to meet diverse construction requirements, making them a cost-effective and efficient option. In summary, steel sheets are highly suitable for construction applications due to their strength, durability, versatility, and various other advantageous properties.

- Q:Can steel sheets be used for industrial machinery or equipment?

- Yes, steel sheets can be used for industrial machinery or equipment. Steel is a durable and strong material that provides structural integrity and stability, making it suitable for various applications in the industrial sector. Steel sheets are commonly used in the fabrication of machine parts, equipment frames, and other components due to their high strength-to-weight ratio and resistance to wear and tear.

- Q:Are steel sheets suitable for magnetic shielding applications?

- Yes, steel sheets are suitable for magnetic shielding applications. Steel is a magnetic material, which means it can effectively redirect magnetic fields, thereby reducing their strength or preventing them from reaching certain areas. Steel sheets can be used as a barrier to shield sensitive electronic equipment and devices from external magnetic interference. The thickness and composition of the steel sheet can be adjusted to provide the desired level of magnetic shielding. Additionally, steel sheets are often cost-effective and readily available, making them a practical choice for magnetic shielding applications.

- Q:What is the difference between a matte and glossy steel sheet?

- The main difference between a matte and glossy steel sheet lies in their surface finish. A matte steel sheet has a dull, non-reflective surface that diffuses light, resulting in a more muted appearance. On the other hand, a glossy steel sheet has a smooth, reflective surface that reflects light, giving it a shiny and polished look.

- Q:How are steel sheets transported?

- Steel sheets are typically transported using trucks or railcars, which are specifically designed to handle heavy and bulky loads. The sheets are often stacked and secured with straps or chains to ensure safe transportation.

- Q:What is the difference between a perforated and expanded steel sheet?

- A perforated steel sheet is a flat metal sheet with evenly spaced holes, typically created through a mechanical punching process. On the other hand, an expanded steel sheet is formed by cutting and stretching a solid metal sheet, resulting in a grid-like pattern with diamond-shaped openings. While both provide ventilation, drainage, and visibility, perforated sheets offer more precise hole patterns and sizes, making them suitable for applications that require specific hole arrangements. Expanded sheets, on the other hand, provide a more rigid structure, making them ideal for walkways, catwalks, and platforms.

- Q:What is the average lifespan of galvanized steel sheets?

- The average lifespan of galvanized steel sheets can vary depending on various factors such as the quality of the galvanization process, environmental conditions, and maintenance. However, in general, galvanized steel sheets can last for several decades, with some estimates suggesting a lifespan of around 50 to 100 years or more.

- Q:What are the common thicknesses for aluminum-coated steel sheets?

- The common thicknesses for aluminum-coated steel sheets typically range from 0.015 inches to 0.125 inches.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corrugated Color Steel Sheet with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 180000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords