prepainted steel roof sheet / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,GB,JIS | Grade: | AISI,ASTM,BS,DIN,GB,JIS | Thickness: | 0.17mm-0.6mm |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | Corrugated sheet | |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Roofing,Ceiling,Roof | Special Use: | High-strength Steel Plate | Width: | 600-1250mm |

| Length: | as per customers request | Zinc coating: | 60-275g/m2 | Surface processing: | Regular spangle,minimal spangle |

Packaging & Delivery

| Packaging Detail: | Standard seaworthy or as your requirement. |

| Delivery Detail: | Within 9 days after confirming the order. |

Specifications

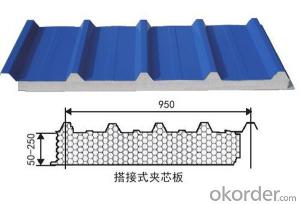

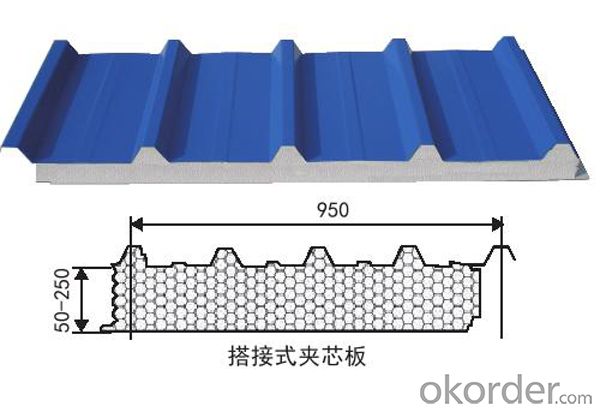

Prepaint corrugated roofing sheet

1.our material are from big mill

2.surface and edge is glossy

3.our package is export pa

Prepainted corrugated steel roofing sheets

Production

Standard | JIS G3302 1998, ASTM A653M/A924M 2004,or according to your request |

Thickness | 0.13mm-1.5mm |

Width | 400mm-1250mm |

Tolerance | Thickness: +/-0.02mm Width:+/-2mm |

Length | We can adjust the length according to your request |

Wave depth | As to requirement |

Zinc Coating | 40g/m2-275g/m2 |

Surface treatment | Color-Coated & Galvanized |

Color | All RAL color |

Coat | 25±5μm on front coating and 7± 2μm on back coating |

Temper | 1.Full hard |

2.Commercial quality | |

3. Dry, chromate, skin passed, tension level, shining. | |

Spangle | Regular spangle, minimized spangle and zero spangle |

Tensile Strength | >300mpa |

Yield Strength | 370-380mpa |

Application | various roofs or walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

MOQ | 50Ton |

Specification

Process ability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

- Q: How do steel sheets perform in thermal conductivity?

- Steel sheets have high thermal conductivity, meaning they are efficient at transferring heat. This property makes them ideal for applications that require heat transfer, such as in heating systems, cookware, and industrial processes.

- Q: What are the different sheet metal forming techniques for steel sheets?

- Steel sheets can be shaped into desired forms and structures using various techniques for sheet metal forming. Below are some common techniques used for steel sheets: 1. Bending: To create angles, curves, or complex shapes, the sheet is bent either manually or with the help of machines like press brakes. 2. Stretch forming: This technique involves stretching and forming the sheet over a mold or die, especially for large and curved components. 3. Deep drawing: By using a punch and a die, the sheet metal is formed into desired shapes, often used for cylindrical or box-like structures such as cans, pots, or automotive components. 4. Roll forming: The sheet metal is passed through a series of rollers to gradually shape it into the desired form. This technique is commonly used for producing long and continuous shapes like rails, tubes, or channels. 5. Spinning: A spinning tool is used to rotate the sheet metal against a mandrel, shaping it into cylindrical or conical shapes such as lampshades or cookware. 6. Embossing: This technique involves stamping a pattern or design onto the sheet metal to create a raised or recessed surface. It is commonly used for decorative purposes or to enhance the structural integrity of the sheet. 7. Hydroforming: Hydraulic pressure is utilized to shape the sheet metal into complex forms, often employed in the creation of automotive components like car body panels or exhaust systems. These examples illustrate the wide range of sheet metal forming techniques available for steel sheets. The choice of technique depends on the desired shape, complexity, and specific requirements of the application.

- Q: What is the price of each steel sheet?

- The price for each steel sheet can differ based on several factors like size, thickness, quality, and market conditions. To obtain an accurate and current price for the particular steel sheet you intend to buy, it is recommended to consult steel suppliers or manufacturers.

- Q: What are the different methods of surface texturing for steel sheets?

- There are several methods of surface texturing for steel sheets, including mechanical methods such as shot blasting, sanding, and grinding, as well as chemical methods such as acid etching and chemical etching. These techniques are used to enhance the appearance of the steel sheets, improve their grip or adhesion properties, or provide a specific texture for functional purposes.

- Q: Steel plate for steel structure, what kind of steel plate is it?

- Carbon steel, low alloy high strength structural steel and high quality carbon structural steel are often used in building engineering.

- Q: How do you determine the quality of steel sheets?

- One way to determine the quality of steel sheets is by examining their composition and properties. This can be done through various tests such as chemical analysis, mechanical testing, and visual inspection. Additionally, factors like the manufacturing process, certifications, and standards met by the steel manufacturer can also provide insights into the quality of the steel sheets.

- Q: What are the different embossing options available for steel sheets?

- There are several embossing options available for steel sheets, including blind embossing, deep embossing, pattern embossing, and textured embossing.

- Q: Can steel sheets be used in telecommunications applications?

- Yes, steel sheets can be used in telecommunications applications. Steel sheets are commonly used for the fabrication of telecom cabinets, enclosures, and equipment racks. They provide durability, strength, and electromagnetic shielding properties, making them suitable for protecting telecommunications equipment and infrastructure.

- Q: What is the typical yield strength of steel sheets?

- The yield strength of steel sheets can vary depending on the grade and type of steel used, with mild steel sheets commonly used in construction and manufacturing having a typical yield strength of around 250 megapascals (MPa) or 36,000 pounds per square inch (psi). Higher strength steels, like high-strength low-alloy (HSLA) steels or advanced high-strength steels (AHSS), can exhibit yield strengths ranging from 300 to 600 MPa (43,500 to 87,000 psi) or even higher. It is important to note that these values are general estimates and specific steel grades may possess slightly different yield strengths.

- Q: Can steel sheets be used for conveyor belts?

- Yes, steel sheets can be used for conveyor belts. Steel is a versatile and durable material that can withstand heavy loads and high temperatures, making it suitable for conveyor belt applications. Steel sheets can be fabricated into various shapes and sizes, allowing for customization based on the specific conveyor system requirements. Additionally, steel sheets offer excellent resistance to wear, impact, and corrosion, ensuring a longer lifespan for the conveyor belt. Overall, steel sheets provide a reliable and robust solution for conveyor belt applications in industries such as manufacturing, mining, and logistics.

Send your message to us

prepainted steel roof sheet / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords