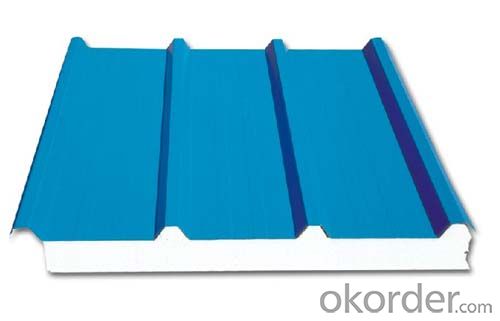

Prepainted steel roof sheet original manufacturer / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,GB,JIS | Grade: | AISI,ASTM,BS,DIN,GB,JIS | Thickness: | 0.17mm-0.6mm |

| Place of Origin: | China (Mainland) | Brand Name: |

| Model Number: | Corrugated sheet |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | Roofing,Ceiling,Roof | Special Use: | High-strength Steel Plate | Width: | 600-1250mm |

| Length: | as per customers request | Zinc coating: | 60-275g/m2 | Surface processing: | Regular spangle,minimal spangle |

Packaging & Delivery

| Packaging Detail: | Standard seaworthy or as your requirement. |

| Delivery Detail: | Within 9 days after confirming the order. |

Specifications

Prepaint corrugated roofing sheet

1.our material are from big mill

2.surface and edge is glossy

3.our package is export pa

Prepainted corrugated steel roofing sheets

Production

Standard | JIS G3302 1998, ASTM A653M/A924M 2004,or according to your request |

Thickness | 0.13mm-1.5mm |

Width | 400mm-1250mm |

Tolerance | Thickness: +/-0.02mm Width:+/-2mm |

Length | We can adjust the length according to your request |

Wave depth | As to requirement |

Zinc Coating | 40g/m2-275g/m2 |

Surface treatment | Color-Coated & Galvanized |

Color | All RAL color |

Coat | 25±5μm on front coating and 7± 2μm on back coating |

Temper | 1.Full hard |

2.Commercial quality | |

3. Dry, chromate, skin passed, tension level, shining. | |

Spangle | Regular spangle, minimized spangle and zero spangle |

Tensile Strength | >300mpa |

Yield Strength | 370-380mpa |

Application | various roofs or walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

MOQ | 50Ton |

Specification

Process ability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

- Q: How are steel sheets used in construction?

- Steel sheets are commonly used in construction for various purposes such as roofing, wall cladding, and structural support. They provide strength, durability, and resistance to harsh weather conditions. Steel sheets can be formed into different shapes and sizes, making them versatile for a wide range of construction applications.

- Q: What is the thickness of the steel sheets?

- The thickness of steel sheets may vary depending on the specific application and requirements. Steel sheets can have thicknesses ranging from 0.4 millimeters to several inches, and commonly used measurements include 0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm, and so on. However, it is worth noting that the thickness can be tailored to suit the intended use, such as in construction, manufacturing, or automotive industries. Therefore, it is crucial to refer to the specifications or contact the manufacturer or supplier to ascertain the precise thickness of the steel sheets in question.

- Q: Can steel sheets be used for modular construction or prefabricated buildings?

- Modular construction and prefabricated buildings can utilize steel sheets for their construction. The strength, durability, and versatility of steel make it a popular choice for this type of construction. Steel sheets can be used to build the framework, walls, and roof of prefabricated buildings. Modular construction involves fabricating building components in a controlled factory environment. Steel sheets can be easily cut, shaped, and welded to create customized building modules. These modules can then be transported to the construction site and quickly assembled. The use of steel sheets ensures precision and consistency in the manufacturing process, resulting in high-quality components. Steel's excellent strength-to-weight ratio makes it ideal for modular construction. Using steel sheets allows for lightweight yet sturdy building modules. This is advantageous for transportation and installation, as it reduces the overall weight and cost associated with shipping and lifting the modules. Furthermore, steel is a durable material that can withstand various weather conditions and environmental factors. It is resistant to fire, termites, and rot, making it a reliable choice for long-lasting prefabricated buildings. Steel sheets can also be treated to enhance their corrosion resistance, protecting the building against rust and deterioration. In addition to its strength and durability, steel offers design flexibility. Steel sheets can be easily manipulated to create different shapes and forms, allowing for diverse architectural styles and configurations. This versatility makes steel an attractive option for architects and builders looking to create aesthetically pleasing and functional prefabricated buildings. Overall, steel sheets are suitable for modular construction and prefabricated buildings due to their strength, durability, versatility, and design flexibility. Using steel in this construction method enables efficient manufacturing, easy transportation, and quick assembly, resulting in cost-effective and high-quality buildings.

- Q: Are steel sheets resistant to impact or puncture?

- Yes, steel sheets are highly resistant to both impact and puncture due to their inherent strength and durability.

- Q: What does "steel plate 10t" mean in the specification column of engineering material?

- The width of the sheet is 500~1500 mm; the thickness is 600~3000 mm. According to the type of steel sheet, ordinary steel, stainless steel, alloy steel, spring steel, stainless steel, tool steel, heat-resistant steel, bearing steel, silicon steel and industrial pure iron sheet; according to professional use, with drums board, enamel board, bulletproof plate; surface coating and plating, plating with zinc thin plate, tin plate, plating lead sheet, plastic composite plate.

- Q: Can steel sheets be painted or coated after installation?

- Yes, steel sheets can be painted or coated after installation. The paint or coating can provide added protection against corrosion and enhance the aesthetic appearance of the steel sheets.

- Q: What are the different grades of steel sheets available?

- There exists a variety of steel sheet grades, each possessing its own distinctive properties and applications. Among the commonly utilized grades are: 1. Carbon Steel: This grade of steel sheet is the most prevalent and extensively employed. It comprises varying carbon levels and is renowned for its robustness and durability. Carbon steel sheets find utility across diverse sectors, including construction, automotive, and manufacturing. 2. Stainless Steel: Distinguished by its elevated chromium content, this steel sheet grade showcases outstanding resistance to corrosion. Industries such as food processing, chemical, and medical frequently employ stainless steel sheets where corrosion resistance plays a pivotal role. 3. Galvanized Steel: To shield against corrosion, this type of steel sheet is coated with a layer of zinc. Galvanized steel sheets often serve in outdoor settings, such as roofing, fences, and gutters, where exposure to moisture and the elements is commonplace. 4. Alloy Steel: By incorporating additional elements like manganese, nickel, or chromium, this grade of steel sheet enhances its mechanical properties. Alloy steel sheets are extensively used in applications demanding heightened strength, such as construction equipment, aircraft components, and machinery. 5. Tool Steel: Designed with elevated hardness and wear resistance, this grade of steel sheet is ideal for tools and dies. Industries such as automotive, aerospace, and manufacturing frequently employ tool steel sheets. It's crucial to note that these represent only a fraction of the available steel sheet grades, as numerous specialized grades are tailored to specific applications. The choice of grade depends on factors such as desired strength, corrosion resistance, and specific application requirements.

- Q: What are the different colors available for coated steel sheets?

- The different colors available for coated steel sheets can vary, but some common options include white, black, gray, blue, red, green, and brown.

- Q: What is the typical weight of steel sheets?

- The typical weight of steel sheets varies depending on their size, thickness, and type of steel being used. Generally, steel sheets can range in weight from a few pounds to several tons. For example, a standard 4x8 foot steel sheet with a thickness of 1/4 inch can weigh around 110 pounds, while a larger 10x10 foot sheet with a thickness of 1 inch can weigh over 1,000 pounds. It is important to note that these are just general estimates, and the weight can vary based on specific factors such as the alloy composition or any additional coatings applied to the steel sheets.

- Q: Are steel sheets suitable for bulletproof applications?

- Yes, steel sheets are suitable for bulletproof applications due to their high strength and durability. They can effectively withstand and absorb the impact of bullets, providing protection against ballistic threats.

Send your message to us

Prepainted steel roof sheet original manufacturer / colour corrugated prepainted sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords