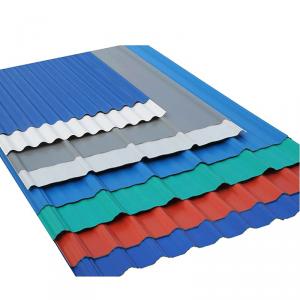

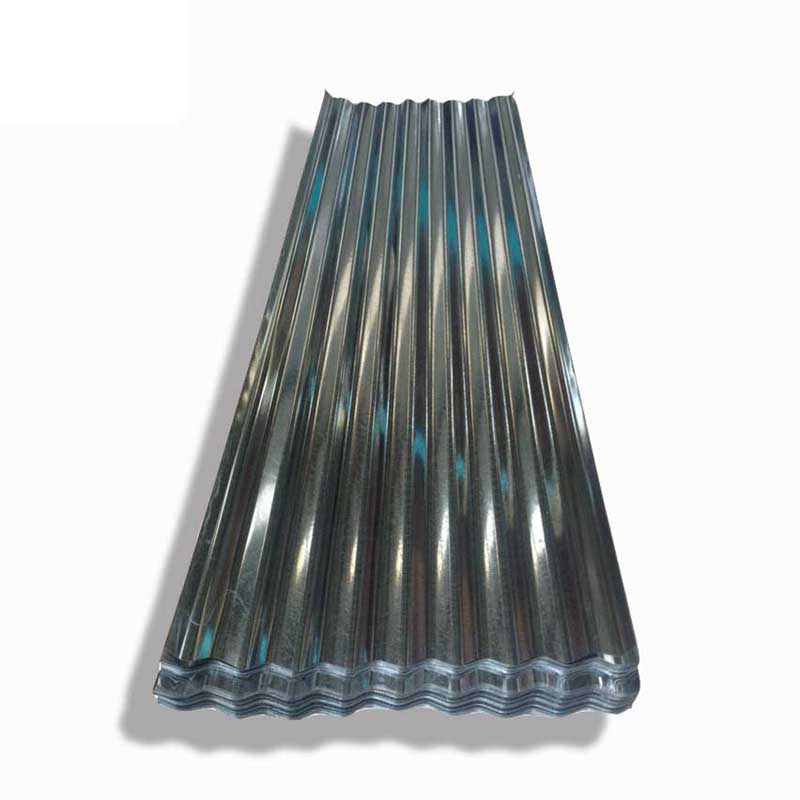

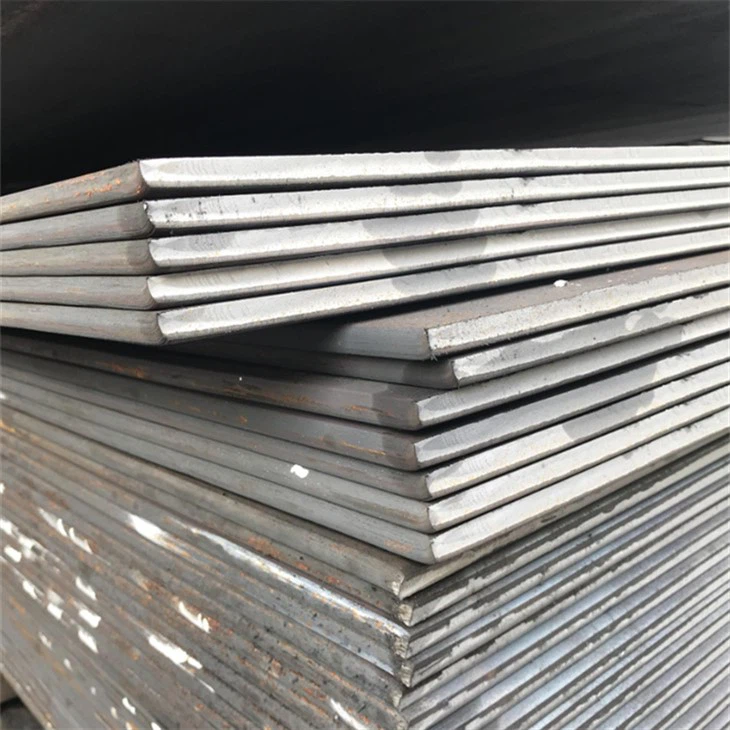

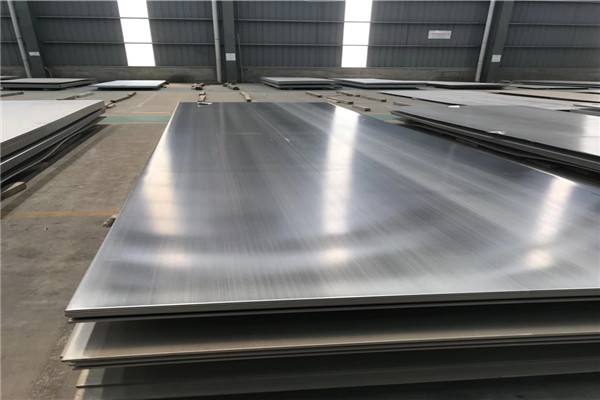

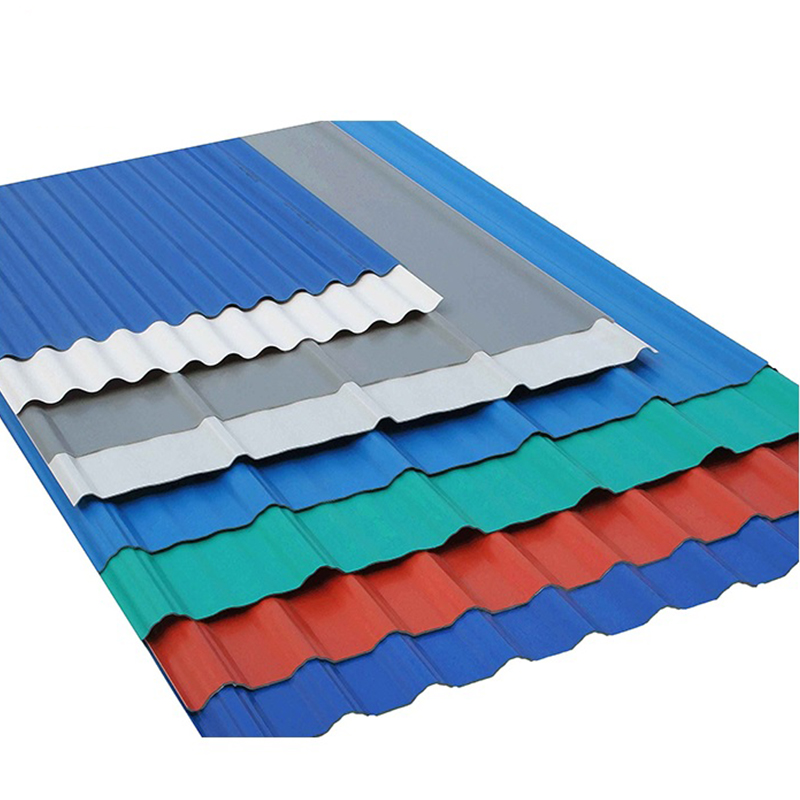

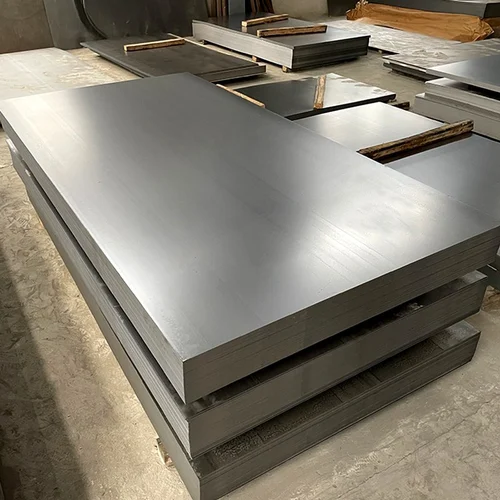

black galvanized steel plate medium plate steel sheet chequered plate corrugated roofing sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

GB

Technique:

Hot Rolled,Cold Rolled

Shape:

steel plate

Surface Treatment:

Galvanized,Black,Color Coated

Steel Grade:

Q235B,Q355B,SS400,S235JR,ASTM A36

Thickness:

0.15-25 mm

Length:

1-12m or customized

Net Weight:

3-4 tons per bundle

Grade | Rank | Chemical Composition( %) | ||||

C | Mn | Si | S | P | ||

Q195 | 0.06~0.12 | 0.25~0.50 | ≤0.3 | ≤0.05 | ≤0.045 | |

Q215 | A | 0.09~0.15 | 0.25~0.55 | ≤0.3 | ≤0.05 | ≤0.045 |

B | ≤0.045 | |||||

Q235 | A | 0.14~0.22 | 0.30~0.65 | ≤0.3 | ≤0.05 | ≤0.045 |

B | 0.12~0.20 | 0.30~0.70 | ≤0.045 | |||

C | ≤0.18 | 0.35~0.80 | - | ≤0.04 | ≤0.04 | |

D | ≤0.17 | ≤0.035 | ≤0.035 | |||

Q255 | A | 0.18~0.28 | 0.40~0.70 | ≤0.3 | ≤0.05 | ≤0.045 |

B | ≤0.045 | |||||

Q275 | 0.28~0.38 | 0.50~0.80 | ≤0.35 | ≤0.05 | ≤0.045 | |

- Q: Are steel sheets suitable for exterior cladding?

- Yes, steel sheets are suitable for exterior cladding. They are durable, weather-resistant, and provide a sleek and modern appearance to buildings. Additionally, steel sheets offer great strength and can withstand harsh environmental conditions, making them a reliable choice for exterior applications.

- Q: Can steel sheets be used for solar panel structures?

- Yes, steel sheets can be used for solar panel structures. Steel is a popular choice for constructing solar panel structures due to its strength, durability, and versatility. Steel sheets can be easily fabricated and shaped to meet specific design requirements, making them suitable for various types of solar panel installations. Additionally, steel has excellent load-bearing capabilities, which is crucial for supporting the weight of solar panels. It is also resistant to corrosion and can withstand harsh weather conditions, making it a reliable material for long-term use in outdoor settings. Overall, the use of steel sheets for solar panel structures is a practical and cost-effective solution.

- Q: What are the different edge treatments available for steel sheets?

- There are several different edge treatments available for steel sheets, including shearing, deburring, chamfering, edge rolling, and edge trimming. These treatments are used to remove sharp edges, create a smooth finish, and improve safety and aesthetics of the steel sheets.

- Q: Are steel sheets suitable for roofing?

- Indeed, steel sheets make an ideal roofing material. Steel, being both sturdy and durable, can endure even the harshest weather conditions, including heavy rainfall, snow, and strong winds. Moreover, it boasts fire resistance, pest resistance, and rot resistance, making it a trustworthy option for long-lasting roofing solutions. In addition to these advantages, steel sheets are lightweight and simple to install, leading to reduced labor and installation expenses. Furthermore, they are available in a wide range of colors and finishes, enabling customization to suit the aesthetic of any structure. All in all, steel sheets offer exceptional protection and durability, which explains their popularity in roofing applications.

- Q: Can steel sheets be used for bulletproof applications?

- Yes, steel sheets can be used for bulletproof applications. Steel is a strong and durable material that can effectively stop bullets from penetrating through it. Bulletproof steel sheets are often used in the manufacturing of armored vehicles, military equipment, and personal protective gear such as bulletproof vests and helmets. The thickness and quality of the steel sheets play a crucial role in determining their bulletproof capabilities. Steel sheets can be designed to withstand different levels of ballistic protection, ranging from handguns to high-powered rifles. Additionally, steel's affordability and ease of production make it a popular choice for bulletproof applications in various industries.

- Q: How are steel sheets protected from rust and corrosion?

- Steel sheets are protected from rust and corrosion through various methods and coatings. One common method is the application of a protective layer called galvanized coating. This involves immersing the steel sheets in a bath of molten zinc, which creates a barrier between the steel and the surrounding environment. The zinc coating acts as a sacrificial anode, meaning that it corrodes first before the steel does. This sacrificial protection prevents rust and corrosion from reaching the steel surface. Another method of protection is through the application of organic coatings such as paint. These coatings provide a physical barrier between the steel and the external environment, preventing moisture and other corrosive elements from coming into contact with the metal. The paint can be applied using various techniques, including spray, roll, or electrostatic deposition. In addition to galvanized coatings and paint, steel sheets can also be protected through the use of other coatings such as epoxy or polyurethane. These coatings provide enhanced protection against corrosion, especially in harsh environments or when the steel sheets are exposed to chemicals or abrasive materials. Regular maintenance and inspections are also crucial in preventing rust and corrosion on steel sheets. This includes cleaning the surface, removing any debris or contaminants, and repairing any damaged or worn-out coatings. By following these preventive measures, steel sheets can remain protected and maintain their structural integrity for a longer lifespan.

- Q: Are steel sheets suitable for magnetic shielding?

- Yes, steel sheets are suitable for magnetic shielding. Steel is a highly magnetically conductive material, which makes it effective at redirecting and absorbing magnetic fields. It can be used to create barriers that prevent magnetic fields from penetrating or escaping certain areas, making it an ideal choice for magnetic shielding applications.

- Q: Can steel sheets be used for electrical conductivity applications?

- No, steel sheets are not typically used for electrical conductivity applications. While steel is a good conductor of heat and has some electrical conductivity, it is not as efficient as other materials specifically designed for electrical conductivity, such as copper or aluminum. Steel sheets are commonly used in applications where strength, durability, and corrosion resistance are important, such as construction, automotive manufacturing, and industrial equipment. For electrical conductivity applications, it is more common to use materials with higher conductivity, such as copper or aluminum. These materials have lower resistance and are better suited for conducting electricity efficiently.

- Q: Are steel sheets suitable for structural applications?

- Yes, steel sheets are suitable for structural applications. Steel sheets are known for their high strength, durability, and versatility, making them an ideal choice for various structural projects. They can be easily manipulated and fabricated into different shapes and sizes, allowing for flexibility in design. Additionally, steel sheets offer excellent load-bearing capacity, resistance to corrosion, and fire protection, making them a reliable and long-lasting option for structural applications.

- Q: What is the difference between a smooth and expanded metal steel sheet?

- A smooth steel sheet refers to a flat surface without any visible patterns or perforations. It is typically used in applications where a sleek appearance is desired, such as in architectural or decorative purposes. Smooth steel sheets are commonly used for countertops, backsplashes, and wall coverings. On the other hand, an expanded metal steel sheet is created by cutting and stretching a solid sheet of steel to create a pattern of interconnected diamond-shaped openings. This process enhances the structural integrity of the sheet while allowing for increased airflow, visibility, and drainage. Expanded metal steel sheets are commonly used in industrial and construction applications, such as walkways, grating, fencing, and machine guards. The main difference between a smooth and expanded metal steel sheet lies in their appearance, functionality, and intended applications. Smooth steel sheets offer a clean and polished look, while expanded metal steel sheets provide strength, ventilation, and versatility. Ultimately, the choice between the two depends on the specific requirements of the project at hand.

Send your message to us

black galvanized steel plate medium plate steel sheet chequered plate corrugated roofing sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Related keywords