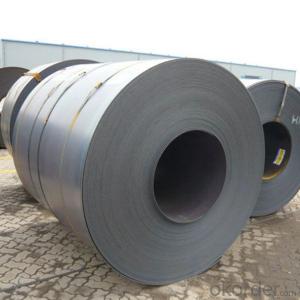

Prime Hot rolled steel from China, CNBM, fast delivery, Q235, SS400

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: | Hot Rolled Steel Coils/Sheets |

Material: | Q195,Q235,A36,SS400,S235JR,Q345,ST37-2, CCSB etc |

Standard : | JIS G3002 GB/T251B |

Technique: | hot rolled |

Thickness | 1.2mm to 200mm |

Tolerance of thickness: | :+/-0.03mm |

Width: | 750mm-2000mm |

Tolerance of width: | :+/-5.00mm (aiming to +/-2.00mm) |

Normal width: | 914mm, 1000mm, 1200mm, 1219mm, 1250mm,1500mm |

Length: | According to requirement |

Coil ID: | 508mm-610mm |

Coil Weight: | 10-25 Metric Tons |

Surface: | Black, Chromate, fingerprint resistant treatment, slight oiled or non-oiled, dry |

Port of Loading: | Tianjin/Shanghai port |

Packaging Details: | Standard export packing or according to the clients required |

Delivery Time | Within 30 days after received 30% deposit or workable L/C |

Payment Terms: | L/C,T/T |

Specifications

hot rolled steel plate

Grade:S235jr S275jr S355jr SS400 A36

Size:1.8 -100x1000 -3000x2000mm

BV approved

Quality Assuranc

A36 Hot Rolled Steel Plates

Carbon Steel Plate

Grade: S235jr S275jr S355jr SS400 Q235 Q345 ASTM A36

Thickness:1.8-100mm

Width:1000-2500mm

Length: 2000-12000mm as request

Mill: qualified steel mill in China

Bundle weight: max 4mt or as request

Package: seaworthy packing ( bared with steel strips )

Payment: L/C,T/T

Shipment: within two months, immediate shipment for stock

- Q: What are the problems encountered in the construction of steel sheet piles? How to deal with

- Based on the soft, sometimes the construction was adopted into the adjacent pile phenomenon, measures is the number of adjacent piles are welded together, and in the application of play pile connected locking coated with butter and other lubricants to reduce resistance

- Q: What does "rolled steel" mean?.

- Generally refers to the thickness below 3, some enterprises have used rolling process, for example, 1.97 of the stainless steel materials market is difficult to buy, the enterprise will use 2 or 2.5 of the material rolling process processing, production of 1.97 thickness.

- Q: Are the steel sheets resistant to bending or warping?

- Yes, steel sheets are highly resistant to bending or warping. Steel is known for its strength and durability, making it a popular choice for various applications where resistance to bending or warping is crucial. The inherent properties of steel, including its high tensile strength and stiffness, allow it to withstand heavy loads and pressure without deforming or warping. Additionally, the uniform and homogeneous structure of steel ensures consistent resistance to bending or warping, making it a reliable material for projects that require stability and structural integrity.

- Q: What is a fixed length steel plate?

- Such as steel plate, its fixed length is six meters, then it is 6 meters, the size will not be uneven. The standard size of the general steel plate is determined according to the national standard, such as 6 meters, 9 meters, etc..

- Q: What is the hardness of the wear-resistant steel plate?

- The main application of impact resistant steel plate:All kinds of medium and heavy stamping, drawing, forming, printing, forging mold.The motor of /EI silicon steel sheet stamping die drawing, canned, impact punch, cold forming.Thick cold tie plate drawing die, stainless steel precision punch, cold extrusion, reverse extrusion convex die.

- Q: What are the standard sizes of steel sheets?

- The standard sizes of steel sheets can vary depending on the type and purpose, but some common dimensions include 4 feet by 8 feet, 5 feet by 10 feet, and 6 feet by 20 feet.

- Q: How do steel sheets perform in cryogenic environments?

- In cryogenic environments, steel sheets prove to be highly effective. Cryogenic temperatures, which often fall below -150°C (-238°F), have the potential to render materials brittle and weaken their strength. Nevertheless, steel possesses remarkable toughness and can endure low temperatures without suffering significant deterioration. Due to their ability to uphold structural integrity and resist fracturing, steel sheets are frequently utilized in cryogenic applications. They exhibit commendable thermal conductivity, enabling efficient heat transfer from the surroundings and preventing the formation of cold spots that could compromise the material's strength. Furthermore, steel's low coefficient of thermal expansion diminishes the likelihood of dimensional alterations caused by extreme temperature fluctuations. This property is of vital importance in cryogenic environments where precision and stability are imperative. Moreover, steel exhibits resistance to embrittlement, a phenomenon that affects select materials when exposed to cryogenic temperatures for prolonged periods. Certain materials become more prone to fracturing due to the diffusion of hydrogen or other gases into their lattice structure. Conversely, steel displays a high resistance to embrittlement, rendering it a dependable choice for cryogenic applications. To sum up, steel sheets perform exceptionally well in cryogenic environments. They maintain their structural integrity, resist embrittlement, and minimize dimensional changes, making them a suitable material for various applications in industries such as aerospace, energy, and research.

- Q: What's the good way to connect two Q235 steel bolts? Why?

- A good plan, two plates have a drilled hole, connected by bolts, locking nut.

- Q: What are the different surface coatings available for steel sheets?

- There are several different surface coatings available for steel sheets. Some common options include galvanized coatings, which provide a layer of zinc to protect against corrosion; paint coatings, which can provide both protection and aesthetic appeal; and organic coatings, which offer additional protection against corrosion and weathering. Additionally, there are specialized coatings such as chrome plating, epoxy coatings, and powder coatings that can be used for specific applications or desired properties.

- Q: Can steel sheets be used for manufacturing kitchen utensils?

- Yes, steel sheets can be used for manufacturing kitchen utensils. Steel is a common material used in the production of utensils due to its durability, heat resistance, and hygienic properties. Steel sheets can be easily shaped and molded into various utensil designs, making them suitable for manufacturing kitchen tools such as pots, pans, cutlery, and other cookware.

Send your message to us

Prime Hot rolled steel from China, CNBM, fast delivery, Q235, SS400

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords