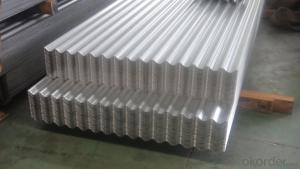

0.12-1.2mm galvanized sheet price metal roofing material galvanized corrugated iron sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

0.12-1.2mm galvanized sheet price metal roofing material galvanized corrugated iron sheet

1> thickness: 0.12mm - 4.5mm

2> width:762mm/914mm/1200mm

3> length:Any length

4> basic material: Galvanized steel sheet, Aluzinc coated steel sheet, Aluminum steel sheet, Prepainted galvanized steel sheet, Prepainted aluzinc steel sheet

5> Zinc (Al) coating: 40g/m2 - 270g/m2

6> shape: corrugated/ trapezoid/Glazed

7> mainly usage: roof and wall

8> Package: standard export package or as customer's requirement

- Q: How do steel sheets compare to other metals in terms of strength?

- Steel sheets are generally stronger than most other metals due to their high tensile strength and excellent resistance to deformation under pressure.

- Q: How do steel sheets perform in fatigue resistance?

- Steel sheets have excellent fatigue resistance due to their high strength and toughness properties. The inherent characteristics of steel, such as its ability to withstand repeated loading, make it highly resistant to fatigue failure. Steel sheets are commonly used in various applications that require durability and prolonged performance under cyclic loading conditions.

- Q: Are steel sheets suitable for automotive chassis?

- Yes, steel sheets are suitable for automotive chassis. Steel is a commonly used material in the automotive industry due to its strength, durability, and cost-effectiveness. Steel sheets provide the required structural integrity and support for the chassis, ensuring the safety of the vehicle and its occupants.

- Q: Are the steel sheets suitable for welding or fabrication purposes?

- Yes, steel sheets are suitable for welding or fabrication purposes. Steel is a versatile and commonly used material in various industries, including construction, automotive, and manufacturing. Steel sheets provide a strong and durable base for welding and fabrication processes. They can be easily cut, shaped, and joined together through welding techniques such as arc welding, MIG welding, or TIG welding. Steel sheets also offer excellent structural integrity and can withstand high temperatures and mechanical stress during welding or fabrication. Additionally, steel sheets are available in different thicknesses and grades, allowing for customization based on specific welding or fabrication requirements.

- Q: Can steel sheets be used for automotive fuel tanks?

- No, steel sheets are not suitable for automotive fuel tanks as they are prone to corrosion and can compromise the safety and integrity of the tank.

- Q: Can steel sheets be used for architectural designs?

- Yes, steel sheets can be used for architectural designs. Steel is a versatile and durable material that can be shaped and formed into various architectural elements such as cladding, roofing, facades, and structural components. Its strength allows for large spans and open spaces, while its aesthetic appeal adds a modern and industrial look to architectural designs. Additionally, steel sheets can be fabricated, painted, or coated to meet specific design requirements and provide longevity and resistance to environmental factors.

- Q: Do steel sheets require any surface treatment before installation?

- Yes, steel sheets typically require surface treatment before installation. This is done to improve the durability and appearance of the steel, as well as to protect it from corrosion. The most common surface treatment methods for steel sheets include galvanization, painting, and powder coating. Galvanization involves applying a protective zinc coating to the steel, which helps to prevent rust and corrosion. Painting and powder coating, on the other hand, involve applying a protective layer of paint or powder to the steel surface. These surface treatments not only provide aesthetic appeal but also enhance the steel's resistance to environmental factors such as moisture, chemicals, and UV radiation. Therefore, it is recommended to apply suitable surface treatment to steel sheets before installation to ensure their longevity and performance.

- Q: Are steel sheets suitable for manufacturing kitchen appliances?

- Yes, steel sheets are suitable for manufacturing kitchen appliances. Steel is a versatile and durable material that is commonly used in the manufacturing industry. It has high strength, which makes it suitable for withstanding the daily wear and tear of kitchen appliances. Steel sheets are also resistant to corrosion, which is important in a kitchen environment where appliances are constantly exposed to water, moisture, and food spills. Additionally, steel is a hygienic material that is easy to clean and maintain, making it ideal for kitchen appliances where cleanliness is crucial. Furthermore, steel sheets can be easily shaped and formed into different designs and sizes, allowing for a wide variety of kitchen appliances to be manufactured. Overall, steel sheets provide the necessary properties and characteristics required for the manufacturing of kitchen appliances.

- Q: What is the difference between a pre-annealed and full hard steel sheet?

- A pre-annealed steel sheet is a sheet that has undergone an annealing process to relieve internal stresses and enhance its formability. It is softer and more malleable compared to a full hard steel sheet. On the other hand, a full hard steel sheet has not undergone any additional treatment after being cold-rolled, making it harder and less ductile. It is typically used for applications requiring higher strength and stiffness.

- Q: Are steel sheets resistant to discoloration from sunlight?

- Yes, steel sheets are resistant to discoloration from sunlight.

Send your message to us

0.12-1.2mm galvanized sheet price metal roofing material galvanized corrugated iron sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords