201/304/316/430 Cold Rolled Stainless Steel Sheet Manufacture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Sheet

304 stainless steel is the most widely used in the 300 series stainless steel. Its anti-corrosion property is stronger than the 200-series stainless steel, but the anti-acid property is worse than 316. 304 stainless steel have a good resistance in high temperature and the excellent corrosion resistance. 304 stainless steel is more expensive than 201, cheaper than the 316.

1. Commodity: 304 Stainless Steel

2. Technique: Cold Rolled/hot rolled Stainless Steel

3. Grade: 304 Stainless Steel

4. Type: Stainless Steel Sheet/coil

5. Finish: 2B/Ba/8K/Emboss/Etch

6. Edge: mill edge /silted edge

7.Size:1219mm*2438mm,1219mm*3048mm,or as customized

Thickness | 0.3mm-3mm |

Width | 1000mm-2000mm |

Length | 1219mm ,3050mm,or as your requirement |

Material | 201/304/316 |

Standard | AISI,DIN,GB,JIS |

Finish | 2B,BA, Hot rolled, No.1-No.4 |

Stock | Width:1000mm,1219mm,1500mm,1800mm,2000mm Length:2000mm,2438mm,2500mm,6000mm,6096mm |

Usage | Tableware, cabinets, cooking utensils, wate heaters, architectural decoration, chemical industry and so on |

Minimum Quantity | 5 pieces |

Technique | Cold rolled and Hot rolled |

Productivity | 10000 tons / month |

Terms of Pa | T/T |

stainless steel coil/sheets surface treatment

Characteristics and application | |

2B | The surface brightness and flatness of 2B is better than 2D. Then through a special surface treatment to improve its mechanical properties, 2B could nearly satisfy comprehensive uses. |

NO.3 | Polished with abrasive belt of git#100#200,have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit#150#180,have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc, |

HL | Polished with abrasive belt of grit#150#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc |

8K | The product have excellent brightness and prefect reflexivity can be the nirror |

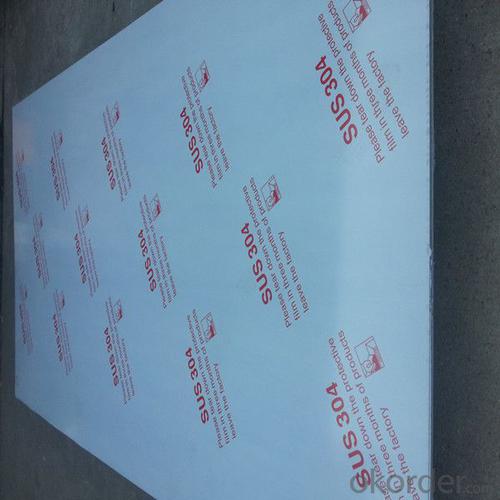

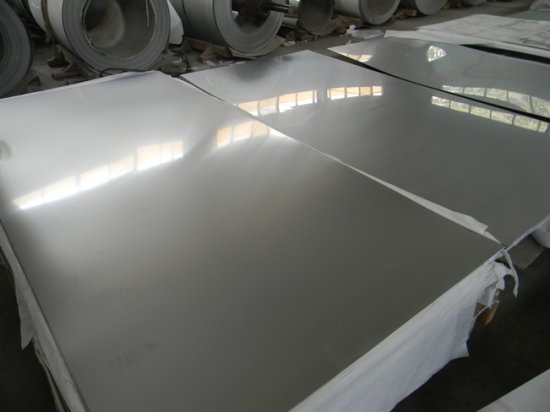

Products Pictures:

cold rolled stainless steel sheet(aisi201 sus304)

hot rolled stainless steel sheet,thick stainless steel sheet

- Q: The difference between 304J1 stainless steel plate and 304 stainless steel plate

- 1. characteristics and uses: steel grades, characteristics, uses304, excellent formability, deep drawing applications - tableware, vacuum cups, sinks, pots and other deep drawing purposes

- Q: Stainless steel plate net price, stainless steel plate net how much one meter?

- Stainless steel punching net is a kind of metal plate net made of stainless steel plate punched by punching machine according to certain pass and mould. Common material: stainless steel punching mesh, divided into several materials, there are 201, 304, 321, 316 and 316L.

- Q: Can stainless steel sheets be used for decorative room dividers or partitions?

- Yes, stainless steel sheets can be used for decorative room dividers or partitions. Stainless steel is a versatile material known for its durability, strength, and resistance to corrosion, making it a popular choice for various applications. When used as room dividers or partitions, stainless steel sheets can add a sleek and modern aesthetic to any space. They can be customized with different finishes, such as brushed, mirrored, or patterned, to create a unique and decorative look. Stainless steel dividers or partitions are also easy to clean and maintain, making them a practical choice for high-traffic areas or commercial spaces. Overall, stainless steel sheets offer both functionality and style, making them suitable for use as decorative room dividers or partitions.

- Q: 304 why is stainless steel magnetic?

- However, due to segregation or improper heat treatment during smelting, there will be a small amount of martensite or ferrite in Austenitic 304 stainless steel. In this way, 304 stainless steel will have a weak magnetic.

- Q: Can stainless steel sheets be used for air conditioning systems?

- Indeed, air conditioning systems can utilize stainless steel sheets. Stainless steel, renowned for its toughness, corrosion resistance, and impressive strength, is a favored material option for various components within air conditioning systems. Specifically, it finds frequent usage in air conditioning ducts, air handling units, heat exchangers, and other components that encounter air or moisture. The stainless steel sheets employed in air conditioning systems usually adhere to a specific grade that suits the intended purpose, thereby guaranteeing peak performance and longevity. All in all, stainless steel sheets represent a dependable and effective selection for air conditioning systems.

- Q: How do stainless steel sheets resist corrosion?

- Due to its unique composition and the presence of a protective oxide layer, stainless steel sheets have the ability to resist corrosion. Stainless steel is comprised of iron, chromium, and other alloying elements like nickel and molybdenum. Chromium is particularly essential for the corrosion resistance of stainless steel. When exposed to oxygen, chromium creates a thin and invisible oxide layer on the surface of the stainless steel, which is referred to as the passive layer. This passive layer acts as a barrier, preventing oxygen and moisture from reaching the underlying metal and safeguarding it against corrosion. This layer is the reason why stainless steel is called "stainless," as it remains free from rust and corrosion. The chromium oxide layer has the ability to self-repair and reform if it gets damaged or scratched, ensuring continuous protection for the stainless steel. This characteristic enables stainless steel sheets to be utilized in various environments, including those with high humidity, exposure to chemicals, and even saltwater. Furthermore, alloying elements such as nickel and molybdenum enhance the corrosion resistance of stainless steel. Nickel enhances the stability and strength of the passive layer, while molybdenum improves resistance against pitting and crevice corrosion. Moreover, surface finishes like polishing or passivation can provide additional protection against corrosion for stainless steel sheets. These processes eliminate any contaminants or impurities from the surface and promote the formation of a stronger and more uniform passive layer. In conclusion, the combination of chromium, other alloying elements, and the protective oxide layer makes stainless steel sheets extremely resistant to corrosion, ensuring durability and longevity in a wide range of applications.

- Q: What are the different edge finishes available for stainless steel sheets?

- For stainless steel sheets, there are multiple edge finishes available, each with its own distinct characteristics and applications. 1. The mill edge is the original edge produced during the rolling process at the mill. It has a slightly rough appearance and may contain mill scale or imperfections. This edge is suitable for industrial or structural use, where aesthetics are not a primary concern. 2. The sheared edge is obtained by cutting or shearing the stainless steel sheet to size. It has a clean-cut, straight appearance and is commonly used in applications where a smooth edge is desired, such as architectural or decorative purposes. 3. After the shearing process, the edges of the stainless steel sheet can be deburred to remove any sharp or rough edges. This creates a smooth and safe edge, making it suitable for applications where safety is a concern, such as food processing or medical equipment. 4. The rolled edge is achieved by rolling the stainless steel sheet, resulting in a rounded or curved edge. This edge finish is often used in applications where safety is important, as it eliminates sharp corners and edges, reducing the risk of injury. 5. A beveled edge is created by cutting or grinding an angle onto the edge of the stainless steel sheet. This edge finish is commonly used in architectural or decorative applications, as it provides a stylish and visually appealing appearance. 6. The polished edge involves polishing the edge of the stainless steel sheet to create a smooth and reflective surface. Polished edges are often used in high-end architectural or decorative applications, as they enhance the overall aesthetic appeal of the stainless steel sheet. When choosing the appropriate edge finish for your application, it is essential to consider factors such as aesthetics, functionality, and safety.

- Q: What are the different types of textured patterns available for stainless steel sheets?

- There are several different types of textured patterns available for stainless steel sheets, each offering a unique aesthetic and functional appeal. Some of the commonly found textured patterns include: 1. Diamond Pattern: This pattern features a raised diamond-shaped design, giving the sheet a beautiful and distinct look. It is commonly used for decorative purposes, offering a sophisticated and modern appearance. 2. Linen Pattern: The linen pattern resembles a woven fabric, with a textured surface that mimics the look of linen cloth. It provides a subtle, elegant, and versatile option for various applications, including architectural and interior design. 3. Quilted Pattern: As the name suggests, the quilted pattern resembles the stitching of a quilt. It creates a three-dimensional effect that adds depth and visual interest to stainless steel sheets. This pattern is often used in automotive, interior design, and decorative applications. 4. Checker Plate Pattern: Also known as diamond plate or tread plate, the checker plate pattern consists of raised diamond-shaped indents on the surface. It provides enhanced slip resistance and is commonly used for flooring, stair treads, and other industrial applications. 5. Bead Blast Pattern: The bead blast pattern involves a sandblasting technique that creates a consistent, matte finish with a slightly textured surface. It offers a modern, sleek appearance, making it popular for architectural and decorative applications. 6. Hammered Pattern: The hammered pattern replicates the texture of a hammered metal surface. It provides a unique and rustic look, often seen in kitchen appliances, countertops, and decorative accents for a vintage or industrial-style design. 7. Leather Grain Pattern: This pattern imitates the texture of leather, offering a soft, luxurious appearance. It is commonly used in high-end interior design projects, such as wall panels, furniture, and elevator interiors. These are just a few examples of the many textured patterns available for stainless steel sheets. Each pattern has its own distinct characteristics, allowing designers and manufacturers to choose the one that best suits their specific requirements and desired aesthetic.

- Q: Are stainless steel sheets suitable for architectural mesh applications?

- Yes, stainless steel sheets are highly suitable for architectural mesh applications due to their durability, resistance to corrosion, and versatility in design. They provide excellent strength and can be easily manipulated into various shapes and patterns, making them ideal for creating aesthetically pleasing and functional architectural elements such as facades, partitions, and decorative screens.

- Q: How do you prevent intergranular corrosion in stainless steel sheets?

- To prevent intergranular corrosion in stainless steel sheets, several methods can be employed. First, the selection of the appropriate stainless steel grade is essential. Grades with a low carbon content, such as 304L or 316L, are less susceptible to intergranular corrosion compared to higher carbon grades. This is due to their ability to minimize the formation of chromium carbide precipitates, which are the main cause of intergranular corrosion. Another method is heat treatment. Processes like solution annealing and quenching can help eliminate or reduce the formation of chromium carbide precipitates. By dissolving existing precipitates and promoting the formation of a protective chromium oxide layer on the surface, the corrosion resistance of the stainless steel is restored. Careful attention must also be given to welding techniques when working with stainless steel sheets. Processes like gas tungsten arc welding (GTAW) or laser welding, which provide precise control over heat input, are preferred. It is also advisable to use low carbon filler metals or consumables specifically designed for intergranular corrosion resistance to minimize the risk of corrosion. After welding, thorough cleaning of the welded area is crucial to remove any contaminants or oxide scales that could promote corrosion. Acid cleaning followed by passivation helps restore the protective oxide layer and enhances the stainless steel's resistance to intergranular corrosion. Lastly, it is important to avoid sensitization, which occurs when stainless steel is exposed to high temperatures for extended periods. Prolonged exposure to temperatures between 450-850°C (842-1562°F) during fabrication or service should be avoided to prevent sensitization and subsequent intergranular corrosion. By implementing these preventive measures, intergranular corrosion in stainless steel sheets can be effectively minimized, ensuring the longevity and performance of the material in various applications.

Send your message to us

201/304/316/430 Cold Rolled Stainless Steel Sheet Manufacture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords