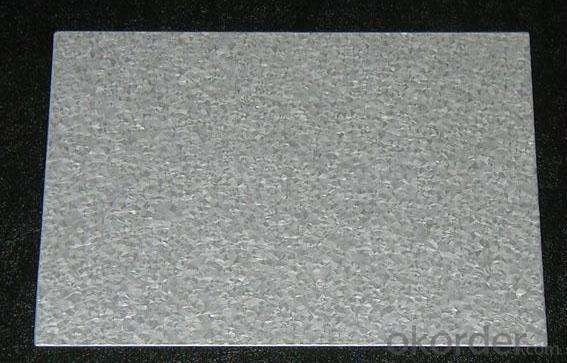

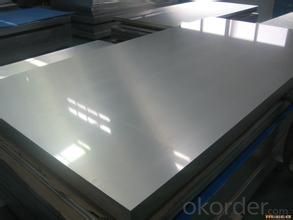

Gavalume steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Standard | GB/T14978, ASTM A792M, JIS G3321, EN10215, etc |

Grade | DX51D-AZ, DX53D-AZ, SGLCC, SS255-550, etc |

Thickness | 0.35-2.3mm |

Width | 600-1270mm |

Inner Diameter | 508mm |

AZ Coated | AZ 50-200 |

Coil Weight | 12Tons max |

Technology | hot dip aluminum and zinc |

Post-processing | Chromated, Anti-finger printed, Oiled, etc |

a.) Construction: roof, walls, garage, soundproof walls, pipes and combined house, etc.

b.) Car: muffler, exhaust pipe, wiper accessories, fuel tanks, truck boxes, etc.

c.) Appliance: refrigerator backplane, gas stove, air conditioner, microwave, LCD border CRT explosion-proof belt, LED backlight, electrical cabinets, etc.

d.) Farm: pigsty, henhouse, granary, greenhouse with pipes etc.

e.) Other: broken thermal insulation cover, heat exchanger, dryer, warm water device, etc.

- Q: What is the process of applying anti-slip coatings to steel sheets?

- The process of applying anti-slip coatings to steel sheets typically involves several steps. First, the steel sheets are thoroughly cleaned and prepared to ensure proper adhesion of the coating. This may involve removing any existing coatings, rust, or contaminants. Next, a primer is applied to the surface to enhance adhesion and provide a smooth base for the anti-slip coating. Once the primer is dry, the anti-slip coating is applied using either a brush, roller, or spray application method, depending on the specific product and desired outcome. The coated steel sheets are then left to cure and dry, typically for a specified period of time. This process helps create a textured surface that provides traction and reduces the risk of slips and falls.

- Q: Can steel sheets be used for structural applications?

- Yes, steel sheets can be used for structural applications. They are commonly used in construction, manufacturing, and engineering industries for building frameworks, bridges, and other load-bearing structures due to their high strength and durability.

- Q: What is the flatness tolerance of steel sheets?

- The flatness tolerance of steel sheets typically varies depending on the specific grade and thickness of the sheet. However, in general, the industry standard flatness tolerance for steel sheets is usually around 0.5% of the sheet's length.

- Q: What are the different alloying elements used in steel sheets?

- Some of the commonly used alloying elements in steel sheets include carbon, manganese, silicon, chromium, nickel, molybdenum, vanadium, and tungsten. These elements are added in varying quantities to enhance specific properties of the steel, such as strength, hardness, corrosion resistance, and heat resistance.

- Q: What are the insulation properties of steel sheets?

- Steel sheets have limited insulation properties as they are strong conductors of heat and electricity. However, their high thermal mass allows them to absorb and slowly release heat, which can provide some degree of insulation. To enhance insulation, steel sheets can be combined with other insulating materials or used in conjunction with insulation systems.

- Q: Can the steel sheets be easily welded?

- Steel sheets can indeed be welded with ease. Joining steel sheets together is commonly achieved through the process of welding. This procedure entails melting the edges of the steel sheets, followed by allowing them to cool and solidify, resulting in a sturdy connection. It is worth mentioning, however, that the ease of welding may vary depending on factors such as the type and thickness of the steel sheets, as well as the expertise and experience of the welder. Furthermore, it is crucial to adhere to appropriate safety measures and welding techniques to guarantee a successful and secure welding procedure.

- Q: Are steel sheets suitable for flooring applications?

- Yes, steel sheets are suitable for flooring applications. Steel sheets are known for their durability, strength, and resistance to wear and tear. They can provide a stable and long-lasting flooring option in various settings, including industrial, commercial, and even residential spaces. Additionally, steel sheets can be easily customized to meet specific design requirements, making them versatile for flooring applications.

- Q: Are steel sheets suitable for harsh weather conditions?

- Yes, steel sheets are highly suitable for harsh weather conditions. Steel is known for its durability, strength, and ability to withstand extreme weather elements such as heavy rain, strong winds, and snow. It is also resistant to corrosion, making it a reliable choice for outdoor applications in harsh climates.

- Q: Can steel sheets be used for electrical conductivity?

- No, steel sheets are not typically used for electrical conductivity as they are not good conductors of electricity.

- Q: How thick is steel filing cabinet usually made of steel plates?

- A lot of people will hold 0.6 of the said 0.8 material, this is because the cold rolled plate after forming electrostatic spraying powder and environmental protection, so it is actually only 0.6mm 0.8mm bare steel, on this point, if you are purchasing large quantities of words, can use vernier caliper to card

Send your message to us

Gavalume steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords