Hot Sale High Quality 16Mo3 Steel Plate from Okorder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of 16Mo3 Steel Plate:

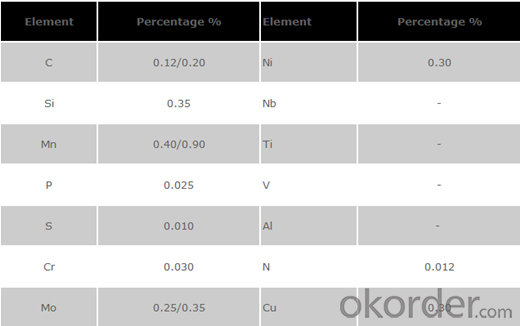

16Mo3 is a EN10028 specified pressure vessel grade chrome molybdenum steel alloy for use in elevated working temperatures. 16Mo3 is used as weldable steel in the fabrication of industrial boilers and steel pressurized vessels found in the oil, gas and chemical industry. Due to the materials chrome and molybdenum content, 16Mo3 has excellent heat resistance and corrosion resistant characteristics.

2、Main Feature of the 16Mo3 Steel Plate:

• High manufacturing accuracy

• High strength

• Wide Market in Middle East, South Asia, Iran, Europe and Russia

3、16Mo3 Steel Plate images:

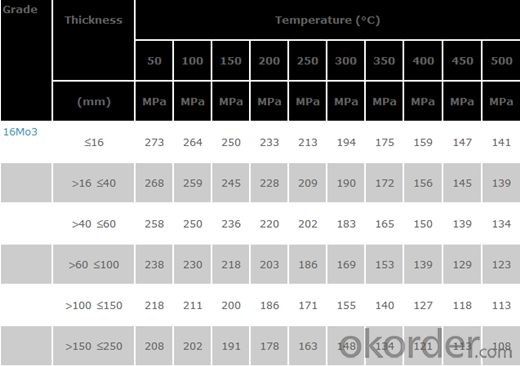

4、16Mo3 Steel Plate Specification:

| Type: | 16Mo3 steel plate |

| Grade: | A36,SS400,SPCC,SPHC, Q195, Q 235,Q345 |

| Thickness: | 1.8-100mm |

| Width: | 1000-2500mm |

| Length: | 2000-12000mm as request |

| Certification: | API&ASTM Standard |

| Delivery Detail: | 15-20days after deposit received or as customer's request |

| Mill: | qualified steel mill in China |

| Service: | OEM Factroy |

5、FAQ of 16Mo3 Steel Plate:

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③How can we receive more information?

You can contact us with Email or just call us directly but on weekend our information service is not available.

- Q: Can steel sheets be bent or shaped?

- Yes, steel sheets can be bent or shaped using various techniques such as cold forming, hot forming, or through the use of specialized machinery such as brakes and presses.

- Q: What are the different types of surface treatments available for steel sheets?

- There are several types of surface treatments available for steel sheets, including galvanizing, painting, powder coating, and plating. Each treatment offers specific benefits in terms of corrosion resistance, aesthetics, and durability, allowing steel sheets to be customized for various applications and environments.

- Q: What is the thickness of the steel sheets?

- The thickness of the steel sheets can vary depending on the specific application and requirements. Common thicknesses for steel sheets range from 0.4 millimeters to several inches, with standard measurements including 0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm, and so on. However, it is important to note that the thickness can be customized based on the intended use, such as for construction, manufacturing, or automotive purposes. Therefore, it is essential to consult the specifications or inquire with the manufacturer or supplier to determine the exact thickness of the steel sheets in question.

- Q: What are the different sizes of steel sheets available?

- Steel sheets are available in a wide range of sizes, catering to various applications and industries. The sizes of steel sheets can vary depending on factors such as thickness, width, and length. In terms of thickness, steel sheets are commonly available in gauges ranging from 7 to 30. The higher the gauge number, the thinner the sheet. Thinner sheets, such as those with a gauge of 30, are often used for applications that require flexibility, while thicker sheets, such as those with a gauge of 7, are typically used for heavy-duty applications that require high strength and durability. When it comes to width, steel sheets are available in a range of options. The most common widths include 36 inches, 48 inches, and 60 inches. However, customized widths can be obtained for specific requirements. Regarding length, steel sheets are typically available in standard lengths of 96 inches and 120 inches. These lengths are commonly used in various industries. However, like width, the length can also be customized to fit specific needs. It is important to note that the availability of different sizes of steel sheets may vary depending on the supplier and the specific grade of steel being used. It is advisable to consult with a steel sheet supplier or manufacturer to determine the exact sizes available for a particular application.

- Q: How do steel sheets perform in terms of water resistance?

- Steel sheets have excellent water resistance due to their inherent properties, such as being non-porous and corrosion-resistant. They effectively prevent water infiltration and can withstand exposure to moisture without compromising their structural integrity.

- Q: What is the weight of a typical steel sheet?

- The weight of a typical steel sheet can vary depending on its dimensions and thickness. However, on average, a standard steel sheet can weigh anywhere from 15 to 30 pounds per square foot.

- Q: Are there any restrictions on the thickness of the steel plate, such as the minimum thickness of the steel plate?

- The information of the building is incomplete and can not be determined. The welding technical parameters will affect the welding method, welding current, welding voltage, welding environment and specifications

- Q: What is the difference between a brushed and etched steel sheet?

- Both a brushed steel sheet and an etched steel sheet are types of metal sheets that have undergone different surface treatments, resulting in unique appearances and characteristics. To create a brushed steel sheet, the surface of the steel is brushed with an abrasive material, typically a wire brush or sandpaper. This process produces a textured pattern of fine lines or scratches on the steel surface. The primary purpose of brushing is to enhance the visual appeal of the steel sheet, giving it a satin-like finish. Brushed steel is commonly used in architectural and design applications where a sleek and contemporary look is desired. It is also popular in kitchen appliances and automotive parts due to its resistance to fingerprints and scratches. On the contrary, an etched steel sheet is made through a chemical or acid etching process. This involves applying an acid-resistant material, such as a resist or stencil, onto the steel surface and then exposing it to an acid solution. The acid selectively eats away at the exposed parts of the steel, creating a pattern or design. Etching is employed to achieve intricate and detailed designs on steel sheets, making it a favored choice in industries like signage, jewelry, and art. The etched patterns can range from simple geometric shapes to elaborate images or text. In essence, the main distinction between a brushed and etched steel sheet lies in the technique employed to achieve their respective surface textures. Brushing generates a consistent pattern of fine lines, resulting in a satin-like finish for aesthetic purposes. On the other hand, etching involves a chemical process that creates intricate and detailed designs on the steel surface.

- Q: How are steel sheets made?

- Steel sheets are made through a process called hot rolling, where steel ingots are heated and passed through a series of rolling mills to reduce their thickness and shape them into flat sheets.

- Q: Can steel sheets be used for shipbuilding?

- Yes, steel sheets can definitely be used for shipbuilding. In fact, steel is one of the most commonly used materials in shipbuilding due to its excellent strength, durability, and resistance to corrosion. Steel sheets are typically used to construct the hull, decks, and other structural components of a ship. The high tensile strength of steel allows ships to withstand the harsh conditions of the ocean, including heavy waves and extreme weather. Additionally, steel sheets can be easily fabricated and welded together, making them ideal for constructing large and complex ship structures. Overall, steel sheets are a reliable and efficient choice for shipbuilding.

Send your message to us

Hot Sale High Quality 16Mo3 Steel Plate from Okorder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords