201 Stainless Steel Sheet Price Per ton

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Commodity | 201 stainless steel sheet |

Specification | Thickness: Cold rolled: 0.3-3mm, Hot Rolled: 3-120mm Width: 500-2000mm Length: 1000-6000mm Customized sizes are accepted |

Standard | ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

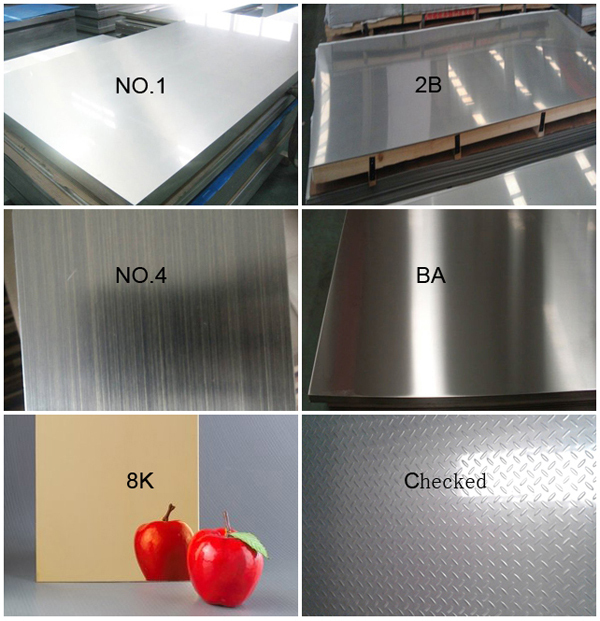

Finish | NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish and so on |

Material | 201, 202, 304, 304L, 310S, 316, 316L, 410, 420, 430, 441, 800H, 904L |

Brand Name | TISCO, Bao Steel, LISCO, JISCO, ZPSS, KRUPP |

Place of Origin | Shanxi of China (Mainland) |

Technical | Cold Rolled, Hot Rolled |

Port of Loading | Tianjin, Shanghai, Ningbo, Guangzhou |

Terms of Delivery | FOB, CFR, CIF, CNF, EXWORK |

Terms of Payment | L/C, T/T (30% deposit) |

Packing | Standard export sea-worthy packing |

Delivery time | Within 7-15 days after receive 30% deposit or as your requirement |

Stock | Ready in stocks |

Our Services

The surface finishes of the stainless steel plate

Surface Finished | Characteristics | Application |

BA | Bright heat treatment after cold rolling. | Kitchen utensil, Kitchen ware, Architectural purpose. |

2B | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to more brighter and smooth surface. | General application medical instruments, Tableware. |

NO.1 | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface. | Chemical industry equipment, Industrial tanks. |

8K(mirror) | A mirrorlike reflective surface by polishing with finer abrasives over 800 mesh. | Refletor, Mirror, Interior- Exterior decoration for building. |

Hair Line | Finished by continuous linear polishing. | Architecture industries, Escalators, Kitchen ware, Vehicles. |

Finished Products

Stocks of the 201 stainless steel sheet

Product Uses

1.Automotive:

Automotive trim and molding /Exhaust-system components, tubular manifolds, mufflers / Catalytic converter shells

2.Construction:

Gutters and downspouts, roofing, siding

3.Kitchenware:

Cooking utensils, dishwashers, ovens, range hoods, refrigerators

4.Chemical processing:

Oil refinery equipment, oil burner and heater parts

5.Appliances:

Hot water tanks, residential furnaces, escalator, doors

6.Power generation:

Heat Exchanger tubing

- Q: Can stainless steel sheets be used for power generation equipment?

- Stainless steel sheets are indeed applicable for power generation equipment. With its versatility, stainless steel possesses a range of advantageous qualities specifically tailored for power generation applications. Its corrosion resistance is exceptional, a paramount characteristic for equipment that comes into contact with water, steam, or other corrosive substances. Moreover, stainless steel exhibits remarkable strength and durability, enabling it to withstand the elevated temperatures and pressures frequently encountered in power generation systems. Another notable attribute is its proficiency as an electrical conductor, rendering it suitable for electrical components and connections within the equipment. Consequently, stainless steel sheets are widely employed in the construction of power generation equipment, including turbines, boilers, heat exchangers, and exhaust systems.

- Q: 304 how can the water stain on the surface of stainless steel plate be formed?

- If you want to scrub the proposal as soon as possible processing, water Jiyue long more difficult to wear off, if it is ferrite, also easy to rust.

- Q: What are the different types of stainless steel sheet finishes for pharmaceutical applications?

- Some of the different types of stainless steel sheet finishes for pharmaceutical applications include 2B finish, 2D finish, BA finish, and mirror finish.

- Q: Can stainless steel sheets be used for medical implants?

- Medical implants can indeed utilize stainless steel sheets. In the medical realm, stainless steel is frequently employed due to its remarkable resistance to corrosion, its strength, and its affordability. It is also biocompatible, meaning that it does not provoke any undesirable reactions when in contact with bodily tissues or fluids. To meet the distinct demands of medical implants, such as orthopedic plates, bone screws, dental implants, and cardiovascular stents, stainless steel sheets can be manufactured into a variety of shapes and sizes. Furthermore, stainless steel is easily cleanable and sterilizable, rendering it well-suited for implantation within the human body. However, it is important to note that different grades of stainless steel may possess varying attributes. As a result, it is crucial to choose the appropriate grade based on the specific application and requirements of the medical implant.

- Q: Are stainless steel sheets suitable for water treatment facilities?

- Yes, stainless steel sheets are highly suitable for water treatment facilities. Stainless steel is corrosion-resistant, durable, and can withstand harsh conditions often found in water treatment processes. Additionally, stainless steel sheets are hygienic, easy to clean, and do not react with water or chemicals, making them an ideal choice for such facilities.

- Q: What are the different types of corrosion that stainless steel sheets can resist?

- Compared to other metals, stainless steel sheets possess remarkable corrosion resistance. They can withstand several forms of corrosion, including: 1. Uniform corrosion: This occurs when the entire surface of the stainless steel sheet is exposed to a corrosive environment. However, stainless steel contains a minimum of 10.5% chromium, which creates a protective oxide layer on the surface, halting further corrosion. 2. Pitting corrosion: Pitting corrosion causes small pits or holes on the stainless steel sheet's surface. Thanks to its high chromium content, stainless steel forms a passive film that prevents pitting corrosion from advancing. 3. Crevice corrosion: This type of corrosion happens in cramped spaces or gaps where stagnant corrosive substances can accumulate. Stainless steel sheets resist crevice corrosion by maintaining their passivity and preventing the buildup of corrosive agents. 4. Stress corrosion cracking (SCC): SCC arises from the combined effects of a corrosive environment and tensile stress. Stainless steel sheets are built to withstand SCC due to their high alloy content and the formation of a protective passive film. 5. Intergranular corrosion: Intergranular corrosion affects the grain boundaries of stainless steel, making it prone to cracking and weakening. However, stainless steel sheets are typically crafted with low carbon content to prevent intergranular corrosion and ensure their durability. In general, stainless steel sheets are highly resistant to various forms of corrosion, making them the preferred choice for multiple applications in industries such as construction, food processing, and marine engineering.

- Q: Can stainless steel sheets be used for kitchen backsplashes?

- Yes, stainless steel sheets can be used for kitchen backsplashes. Stainless steel is a popular choice for backsplashes due to its durability, resistance to stains and heat, and easy maintenance. It provides a sleek and modern look to the kitchen while also protecting the walls from splatters and spills.

- Q: Can stainless steel sheets be used for architectural columns?

- Architectural columns can indeed utilize stainless steel sheets. Renowned for its durability and versatility, stainless steel proves to be an exceptional material, providing outstanding resistance against corrosion. This exceptional trait makes it a fitting choice for both indoor and outdoor applications. The polished and contemporary look of stainless steel further enhances the visual allure of architectural designs. Moreover, stainless steel sheets can be tailor-made into different sizes and shapes, offering flexibility in column design. Be it for residential, commercial, or industrial ventures, stainless steel sheets emerge as a favored option for architectural columns, owing to their robustness, long lifespan, and captivating appearance.

- Q: Can stainless steel sheets be used for stadium seating?

- Yes, stainless steel sheets can be used for stadium seating. Stainless steel is a durable and corrosion-resistant material, making it suitable for outdoor applications like stadium seating. Its strength and stability make it a reliable choice for providing seating arrangements in stadiums.

- Q: Are stainless steel sheets fire resistant?

- Stainless steel sheets have excellent fire resistance properties. Due to their high melting point and low thermal conductivity, stainless steel is able to withstand high temperatures for prolonged periods of time without undergoing significant structural changes or losing their strength. This makes stainless steel sheets highly resistant to fire and heat damage. Additionally, stainless steel does not release toxic fumes when exposed to fire, which further enhances its safety in fire-prone environments. As a result, stainless steel sheets are commonly used in applications where fire resistance is a critical requirement, such as in the construction of fire doors, fire escapes, and fire-resistant enclosures.

Send your message to us

201 Stainless Steel Sheet Price Per ton

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords