321 Stainless Steel Sheet price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specification:

321 stainless steel price per kg

1.Grade:304,304L,316,316L,309S,310S,904L,etc

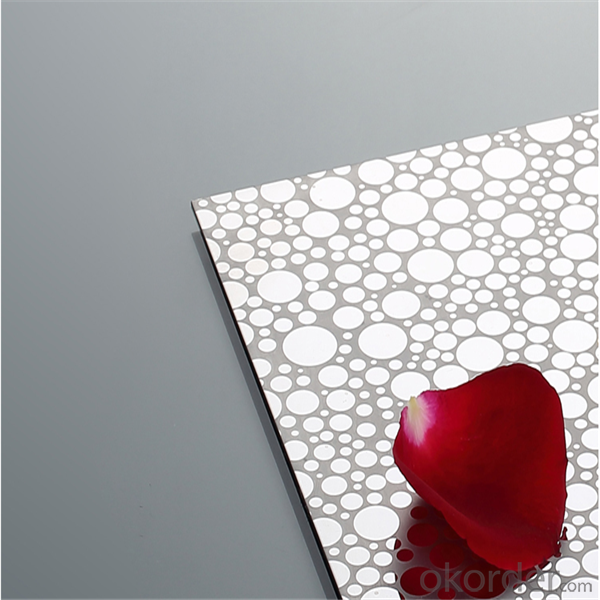

2.Finish:2B,BA,HL,Brush,NO.1,NO.4,Mirror and so on.

3.Standards:JIS,AISI,ASTM,GB

4.Thick;0.3mm--150mm

5.Wide;1000mm--2000mm

6.Length;1000mm--6000mm

7.Packing: standard export sea-worthy packing or as the customers’ requirement

8.Payment:L/C and T/T

9.Shipment:about 10 days after payment terms.

10.Trade Terms:FOB Shanghai.

11.Application construction, building, kitchwares, medical industry, eletricity industry and so on.

We have very good connection with factory, so we can provide competitive price to you, if u are intresented in our products, pls feel free to contract us.

Your enquiry will be welcome.

Details:

Type | Stainless steel sheet(cold rolled or hot rolled) |

Thinckness | 0.3mm - 150mm or as customer's requirement |

Widthness | 1000mm - 2000mm or as customer's requirement |

Length | 1000mm - 6000mm or as customer's requirement |

Finish | 2B,BA,HL,Brush,NO.1,NO.4,Mirror and so on. |

Standard | JIAISI, ASTM, GB, |

Material | 304, 304L, 316, 316L, 309S, 310S, 321, etc |

Application range | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum,boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | About 7 days after the order |

Quality | Prime |

Productivity | 500 tons/week |

Note | Other standards can be produced as the customers’ requirement |

- Q:Are stainless steel sheets resistant to fire?

- Yes, stainless steel sheets are highly resistant to fire. Stainless steel is a type of metal alloy that contains a high percentage of chromium, which forms a protective layer of chromium oxide on the surface when exposed to air or moisture. This chromium oxide layer acts as a barrier, preventing oxygen from reaching the underlying metal and thus making stainless steel highly resistant to corrosion and fire. Stainless steel sheets have a melting point of around 2750°F (1510°C), which is significantly higher than the temperatures typically encountered in most fire scenarios. This means that stainless steel can withstand intense heat for a prolonged period without deforming or losing its structural integrity. Furthermore, stainless steel is non-combustible and does not contribute to the spread of flames. It does not release harmful gases or toxic fumes when exposed to fire, making it a safe material for use in various applications where fire resistance is crucial, such as in building construction, industrial equipment, and transportation. Due to these properties, stainless steel sheets are widely used in fire-rated structures, including fire doors, fire-rated walls, and fire-resistant enclosures. They provide an effective barrier against the heat and flames, helping to contain the fire and protect the surrounding areas. However, it is important to note that while stainless steel is highly resistant to fire, it can still be affected by extremely high temperatures or prolonged exposure to fire. In such cases, the material may experience some degree of distortion or damage. Therefore, it is essential to consider the specific fire rating requirements and consult with experts to ensure the appropriate selection and installation of stainless steel sheets in fire-resistant applications.

- Q:Are stainless steel sheets suitable for heat transfer equipment?

- Stainless steel sheets are indeed a suitable option for heat transfer equipment. The reason lies in the remarkable thermal conductivity properties of stainless steel, enabling it to effectively transfer heat between different mediums. Its ability to endure high temperatures without warping or deforming makes it particularly well-suited for heat transfer applications. Moreover, stainless steel's resistance to corrosion guarantees the equipment's durability and longevity. Additionally, its hygienic qualities make it a fitting choice for industries such as food and pharmaceuticals, where cleanliness is of utmost importance. In conclusion, stainless steel sheets are a dependable and efficient selection for heat transfer equipment.

- Q:Can stainless steel sheets be used for automotive exhaust systems?

- Indeed, automotive exhaust systems can utilize stainless steel sheets. The use of stainless steel is prevalent in exhaust systems owing to its remarkable resistance to corrosion, ability to withstand high temperatures, and durability. It successfully endures the harsh conditions present in exhaust systems, encompassing intense heat, moisture, and chemicals. Stainless steel sheets can be shaped and manufactured into diverse components of the exhaust system, including pipes, mufflers, and catalytic converters. They offer enduring performance, minimize the likelihood of rust and corrosion, and enhance the overall efficiency and longevity of the automotive exhaust system.

- Q:What is the weight of stainless steel sheets?

- The weight of stainless steel sheets can vary depending on their thickness and dimensions. Generally, stainless steel sheets have a density of 8 grams per cubic centimeter. To calculate the weight of a stainless steel sheet, you would need to know the dimensions (length, width, and thickness) and multiply them together to find the volume. Then, you can multiply the volume by the density to find the weight.

- Q:What is the minimum thickness of stainless steel sheets available?

- The minimum thickness of stainless steel sheets available can vary depending on the manufacturer and the specific grade of stainless steel being used. Generally, the thinnest stainless steel sheets available range from 0.4mm to 0.5mm. However, it is important to note that some manufacturers may offer thinner sheets, such as 0.3mm, but these may be more specialized or less commonly available. If you require a specific thickness for your project, it is recommended to consult with stainless steel suppliers or manufacturers to determine the options available to you.

- Q:What's the cheapest kind of stainless steel plate? What's the model and how much is it?

- Ferritic stainless steel (with magnetic) inside 409 minimum, average price of 7800 yuan / ton, including tax, the proportion of 7.75, the formula is the same as above

- Q:Are stainless steel sheets resistant to hydrogen embrittlement?

- Yes, stainless steel sheets are generally resistant to hydrogen embrittlement due to their high strength and low reactivity with hydrogen gas.

- Q:Can stainless steel sheets be used for decorative room dividers or partitions?

- Yes, stainless steel sheets can be used for decorative room dividers or partitions. Stainless steel is a versatile material known for its durability, strength, and resistance to corrosion, making it a popular choice for various applications. When used as room dividers or partitions, stainless steel sheets can add a sleek and modern aesthetic to any space. They can be customized with different finishes, such as brushed, mirrored, or patterned, to create a unique and decorative look. Stainless steel dividers or partitions are also easy to clean and maintain, making them a practical choice for high-traffic areas or commercial spaces. Overall, stainless steel sheets offer both functionality and style, making them suitable for use as decorative room dividers or partitions.

- Q:Are stainless steel sheets suitable for medical implants?

- Yes, stainless steel sheets are suitable for medical implants. Stainless steel is commonly used in medical implants due to its excellent corrosion resistance, mechanical strength, and biocompatibility. It can be easily sterilized, is durable, and has a long track record of successful use in various medical applications.

- Q:How do you determine the best thickness of stainless steel sheet for a specific application?

- To determine the best thickness of stainless steel sheet for a specific application, several factors need to be considered. Firstly, the intended use of the stainless steel sheet is crucial. Different applications require different levels of strength, durability, and resistance to corrosion. For example, if the sheet will be used in a high-stress environment or exposed to harsh chemicals, a thicker gauge stainless steel sheet would be suitable to ensure sufficient strength and corrosion resistance. Secondly, the size and dimensions of the application should be taken into account. Larger structures or components may require thicker stainless steel sheets to maintain structural integrity and prevent deformation under load. Conversely, smaller or more delicate applications may benefit from thinner sheets to reduce weight and improve flexibility. Moreover, considering the expected lifespan and maintenance requirements is essential. Thicker stainless steel sheets generally offer greater longevity and can withstand more wear and tear. However, if the application requires frequent cleaning or maintenance, a thinner sheet may be more practical. Additionally, budgetary constraints should be taken into consideration. Thicker stainless steel sheets tend to be more expensive due to the increased material cost and manufacturing complexity. Balancing the desired performance with available resources is crucial to determine the most cost-effective thickness. Lastly, consulting industry standards, guidelines, and experts can provide valuable insights. Various industries have specific requirements for stainless steel sheet thickness based on their experiences and safety standards. Engaging with professionals can help to ensure the chosen thickness meets the necessary specifications and regulations. In summary, determining the best thickness of stainless steel sheet for a specific application involves considering the intended use, size, expected lifespan, maintenance requirements, budget, and seeking guidance from industry experts. By carefully evaluating these factors, one can make an informed decision to select the most suitable thickness for their particular needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

321 Stainless Steel Sheet price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords