Steel Sheet 3316 Stainless Steel Factory Price Half Copper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Basic Information:

Material | ASTM 3316 | ||

Chemical Composition | Mechanical Properties(In Quenched & Tempered State) | ||

C | 0.1-0.23 | Tensile strength(MPA) | ≥1175 |

Si | 0.17-0.37 | Yield strength (MPA) | ≥1080 |

Mn | 0.30-0.60 | Elongation(δ5/%) | ≥10 |

Cu | ≤0.030 | Reduction in Area (ψ/%) | ≥45 |

Mo | - | Impact (J) | ≥63 |

P | ≤0.035 |

Hardness | ≤269HB

|

S | ≤0.035 | ||

Cr | 1.25-1.65 | ||

Ni | 3.25-3.65 | ||

2.Product Application Areas:

Our products have been used in all kinds of areas, such as aviation,aerospace,navigation,nuclear energy,chemical industry,

electronic information,achine manufacture, petrochemical, automotive,instrument and meter, Communication ,transportation, and medical instruments, etc.

3.Similar steel grade & equivalent steel materials:

USA | Japanese | Gemany | British | France | International | Chinese |

ASTM&AISI&SAE | JIS | EN DIN | EN BS | EN NF | ISO | GB |

3316 | SNC815 | 15NiCr13(1.5752) | - | 20Cr2Ni4 | ||

High strength and resistance to intergranular corrosion and chloride stress corrosion is improved obviously. Stainless steel has great corrosion performance.

Product Sales Information:

Material | ASTM 3316 Alloy Structural Steel |

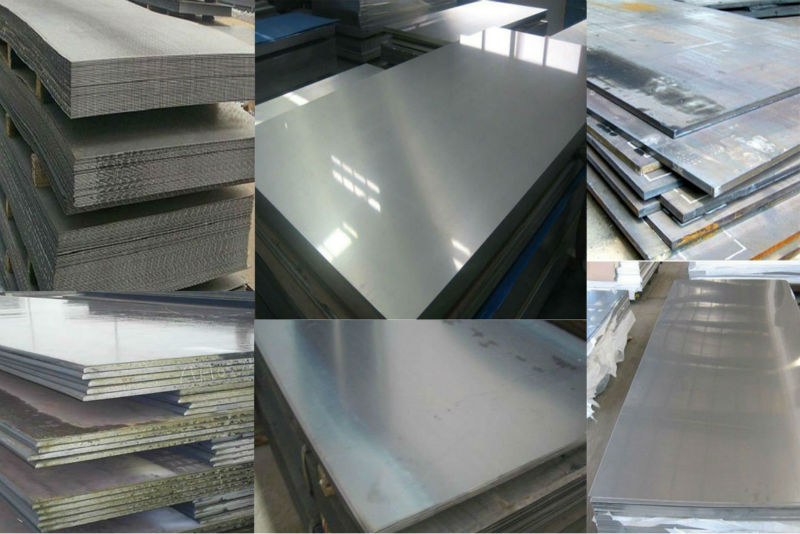

Size | Thickness:20~50mm Width:200-1000mm Length: 4~6m |

Origin place | Made In China |

Delivery Condition | Hot rolled,cold drawn,forged |

Surface require | Black,grinding,bright,polish |

Heat treatment | Quenched,Tempered,annealed |

Packing | seaworthy packing ,wooden case ,carton,woven bag or at client's requires |

Delivery time | In 10-50 days |

Trade Term | EXW,FOB,CIF |

Payments | T/T or L/C at sight |

Port | China main Port,such as shanghai,Dalian,Shenzhen port. |

MOQ | 1 Ton |

Company Main Products:

Alloy Steel | 5140,5115,5120,5130,5145,4118,4130,4135,6150,5115,4142,4130,4118,6150,4140,4720,4320 ,E9310,8620,4340 |

Tool Steel | H13,1.2344,SKD61,D2,SKD11,1.2379,1.2510,01,SKS3,95MnWCr5,D3,SKD1,1.2419, SKS31,H21,SKD5,1.2581,P20,35CrMo7,1.2738,1.2316,M2 |

Bearing Steel | GCr15,52100,SUJ1,SUJ2,100Cr6,1.2067,55C,8620,4320,9310,440C,M50 |

Spring Steel | 9260,SUP6,SUP7,1.7108,54SiCr6,1.7102,5155,SUP9,1.7176,5160,1.7177,6150, SUP10,51CrV4,1.8159 |

Stainless Steel | 321,sus321,1.4541,304,SUS304,1.4301,410,SUS410,1.4006,420,1.4021,1.4028, 434,1.4113,316L,SUS316L,1.4435,630,1.4542,431,1.4057,201,202,301 |

Other Products:

- Q: What is the bending strength of stainless steel sheets?

- The bending strength of stainless steel sheets can vary depending on the specific grade and thickness of the sheet. However, stainless steel is generally known for its high strength and rigidity, making it suitable for various applications that require strong and durable materials.

- Q: Are stainless steel sheets suitable for storage cabinets?

- Yes, stainless steel sheets are suitable for storage cabinets. Stainless steel is known for its durability, strength, and resistance to corrosion, making it an excellent choice for storage cabinets. Stainless steel sheets are able to withstand heavy loads and can resist damage from moisture, heat, and chemicals. Additionally, stainless steel is easy to clean and maintain, making it a hygienic option for storage cabinets. Overall, stainless steel sheets provide a long-lasting and reliable solution for storage cabinets in various environments such as kitchens, laboratories, and industrial settings.

- Q: Can stainless steel sheets be used for outdoor furniture or fixtures?

- Yes, stainless steel sheets can be used for outdoor furniture or fixtures. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for outdoor use. It is resistant to rust and can withstand various weather conditions, including rain, snow, and high humidity. Additionally, stainless steel has a sleek and modern appearance, making it a popular choice for outdoor furniture and fixtures. It is often used in the construction of outdoor tables, chairs, benches, grills, and other fixtures due to its strength, longevity, and resistance to environmental factors.

- Q: How do you remove fingerprints from brushed stainless steel sheets?

- To remove fingerprints from brushed stainless steel sheets, you can use a microfiber cloth or a soft cloth dampened with warm soapy water to gently wipe away the fingerprints. Avoid using abrasive cleansers or scrub brushes as they can damage the brushed finish. Dry the surface thoroughly with a clean cloth to prevent water spots.

- Q: Who knows the production process of stainless steel plate?

- Stainless steel surface process:Stainless steel has a variety of surface processing to broaden its application areas, different surface processing makes the surface of stainless steel different, making it unique in the application.The corrosion environment requires smooth surface for smooth surface is not easy to fouling. Deposition of dirt can make stainless steel rusty and even cause corrosion.In the spacious lobby, stainless steel is the most commonly used decorative materials for the elevator decoration, although the surface of the fingerprint can erase, but affect the appearance, it is best to use the appropriate surface to prevent leaving fingerprints.

- Q: What are the different types of stainless steel alloys used for sheets?

- There are several different types of stainless steel alloys commonly used for sheets, such as austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, and duplex stainless steel. Each alloy has its own unique properties and characteristics, making them suitable for various applications and environments.

- Q: How do you remove scratches from mirror-finish stainless steel sheets?

- To remove scratches from mirror-finish stainless steel sheets, you can follow these steps: 1. Clean the surface: Start by cleaning the stainless steel sheet with a mild detergent or stainless steel cleaner to remove any dirt, grime, or oils. Ensure the surface is completely dry before proceeding. 2. Assess the depth of the scratch: Determine the severity of the scratch by running your fingernail over it. If the scratch is superficial and can barely be felt, it can be easily repaired. However, deeper scratches may require professional assistance. 3. Remove minor scratches: For minor scratches, you can use a non-abrasive cleaner or toothpaste. Apply a small amount to a soft cloth or sponge and gently rub the scratched area in a circular motion. Rinse the area thoroughly and wipe dry with a clean cloth. 4. Utilize metal polish: If the scratch is still visible after using a non-abrasive cleaner, you can try using a metal polish specifically designed for stainless steel. Apply a small amount of polish to a clean, soft cloth and rub it onto the scratched area in a circular motion. Continue until the scratch fades away, then rinse and dry. 5. Deep scratch repair: If the scratches are deeper or more extensive, you may need to consult a professional stainless steel restoration expert. They can assess the damage and recommend the best course of action, which may involve sanding and polishing the surface to restore its original mirror finish. Remember, it is crucial to test any cleaning or polishing products in an inconspicuous area first to ensure they do not cause any damage or discoloration. Additionally, always follow the manufacturer's instructions when using any cleaning or polishing products.

- Q: Are stainless steel sheets suitable for pharmaceutical applications?

- Yes, stainless steel sheets are suitable for pharmaceutical applications. Stainless steel is resistant to corrosion, easy to clean, and has excellent hygienic properties, making it ideal for use in pharmaceutical manufacturing processes where hygiene and cleanliness are crucial. Additionally, stainless steel sheets can withstand high temperatures and pressures, making them suitable for various pharmaceutical equipment and storage containers.

- Q: Can stainless steel sheets be used for elevator cabins?

- Yes, stainless steel sheets can be used for elevator cabins. Stainless steel is a durable and corrosion-resistant material, making it suitable for high-traffic areas like elevator cabins. Additionally, stainless steel has a sleek and modern appearance, making it a popular choice for elevator interiors.

- Q: Can stainless steel sheets be used for electrical enclosures?

- Yes, stainless steel sheets can be used for electrical enclosures. Stainless steel is a highly durable and corrosion-resistant material that provides excellent protection for electrical components. It has high strength and can withstand harsh environmental conditions, making it suitable for both indoor and outdoor applications. Additionally, stainless steel has good conductivity and can dissipate heat efficiently, which is crucial for maintaining proper temperatures within the enclosure. This makes stainless steel sheets a reliable choice for electrical enclosures, offering long-lasting performance and protection for the enclosed electrical equipment.

Send your message to us

Steel Sheet 3316 Stainless Steel Factory Price Half Copper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords