Factory price 304L stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

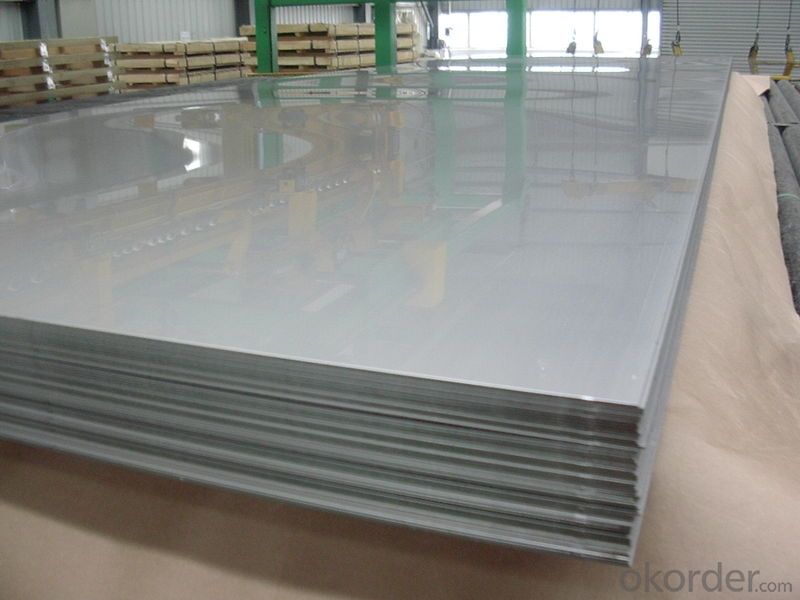

Factory price 304L stainless steel sheet !!!

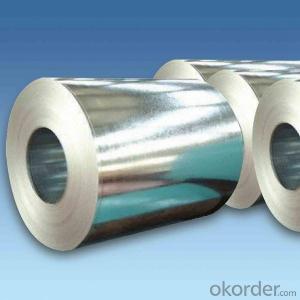

1.hot rolled and cold rolled stainless steel sheet detailed information:

Type | 304L stainless steel sheet |

Thinckness | 0.3mm-60mm |

Widthness | 50mm~2000mm |

Length | 2000mm~8000mm or as request |

Brand name | TISCO |

Standard | JIS, AISI, ASTM, GB, DIN, EN |

Material | 304L,304,316,316L,309S,310S,321,317,301,904L,201,202,430,410,420, etc |

Surface | 2B,BA,HL,BK,NO.1,NO.4,etc |

Certificate | We accept the third inspections |

Application | Bridge, Shipbuilding,roofing,Car, etc |

Payment | T/T, 30% deposit, blance before loading, L/C |

Note | We can produce other standard as the customers’ require |

2. 304L stainless steel sheet Applications :

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

Why do you choose us?

1) Our products are high quality and best price.

2)We have experience in this line for many years.

3)We have professional team and the factory.

4)It's very important for a company to be honest in the process of trading and so do we.

- Q: Are stainless steel pipes suitable for desalination plants?

- Yes, stainless steel pipes are suitable for desalination plants. Desalination plants are facilities designed to remove salt and other impurities from seawater or brackish water to produce freshwater. These plants require pipes that can withstand the harsh conditions of the desalination process, which involves high pressure, high temperatures, and exposure to corrosive substances. Stainless steel pipes are an excellent choice for desalination plants due to their inherent corrosion resistance properties. Stainless steel contains a minimum of 10.5% chromium, which forms a thin protective oxide layer on the surface of the material, preventing corrosion and ensuring longevity. This oxide layer acts as a barrier, protecting the steel from the corrosive effects of seawater, brine, and other chemicals used in the desalination process. Furthermore, stainless steel pipes are highly durable and can withstand extreme temperatures and pressures without compromising their structural integrity. They are also resistant to scaling and fouling, which are common issues in desalination plants due to the high concentration of minerals and salts in the water. In addition to their corrosion resistance and durability, stainless steel pipes are also hygienic and easy to clean, making them suitable for desalination plants that require regular maintenance and cleaning to ensure efficient and reliable operation. Overall, stainless steel pipes are an ideal choice for desalination plants due to their corrosion resistance, durability, and ease of maintenance. They can effectively handle the demanding conditions of the desalination process, ensuring the production of high-quality freshwater.

- Q: What are the different types of stainless steel pipe flanges?

- Various types of stainless steel pipe flanges are available to meet specific application needs and requirements. Some commonly used types include: 1. Weld Neck Flanges: These flanges have a tapered hub and are welded to the pipe, offering exceptional strength and durability. They are suitable for high-pressure and high-temperature applications. 2. Slip-On Flanges: These flanges slide onto the pipe and are then welded in place, providing a secure connection. They are easy to install and commonly used in low-pressure and non-critical applications. 3. Socket Weld Flanges: These flanges have a socket-like end that fits over the pipe and is then welded, ensuring leak resistance. They are used for smaller pipes. 4. Threaded Flanges: These flanges can be screwed onto the pipe due to their internal threads. They are easy to install and remove, making them suitable for low-pressure applications. 5. Lap Joint Flanges: These flanges consist of a stub end and a loose backing flange, allowing for frequent dismantling or precise alignment. 6. Blind Flanges: These solid flanges have no bore and are perfect for closing off the end of a pipe. They are commonly used in piping systems that require periodic inspection or cleaning. 7. Orifice Flanges: These flanges have concentric or eccentric holes to measure fluid flow rate. They find applications in flow measurement. 8. Spectacle Blind Flanges: These flanges combine a blind flange with a spacer and are used to separate pipe system sections. They can be easily removed for maintenance or repair. It is crucial to choose the appropriate stainless steel pipe flange type based on specific application requirements, including pressure, temperature, and fluid compatibility.

- Q: Are stainless steel pipes resistant to hydrogen embrittlement?

- Generally, stainless steel pipes are resistant to hydrogen embrittlement. Hydrogen embrittlement refers to the phenomenon where hydrogen can penetrate certain metals, making them brittle and prone to cracking or failure. Stainless steel, on the other hand, possesses a high resistance to hydrogen embrittlement due to its unique composition. It primarily consists of iron, chromium, and other alloying elements like nickel and molybdenum. The chromium in stainless steel forms a passive oxide layer on the surface, which offers excellent corrosion resistance and acts as a barrier against hydrogen diffusion. Moreover, stainless steel pipes are often made using specific grades, such as austenitic or duplex stainless steels, which exhibit even greater resistance to hydrogen embrittlement. These grades contain higher amounts of alloying elements, further enhancing their ability to resist hydrogen attack. However, it is important to acknowledge that stainless steel can still be vulnerable to hydrogen embrittlement under certain conditions, such as high temperatures and high-pressure environments. Therefore, it is crucial to carefully consider the specific application and operating conditions when selecting stainless steel pipes to ensure their resistance to hydrogen embrittlement.

- Q: What are the different types of stainless steel pipe tees?

- There are several different types of stainless steel pipe tees, each designed for specific applications and requirements. 1. Equal Tee: This type of tee has three outlets of the same size, forming a 90-degree angle. It is commonly used to branch off or combine flow in a pipeline with equal diameters. 2. Reducing Tee: As the name suggests, a reducing tee has one outlet smaller than the other two. It is used to connect pipes of different sizes, allowing for a smooth transition in the flow of fluids or gases. 3. Barred Tee: This tee has a bar welded across the branch opening, providing additional support and reinforcement. It is commonly used in high-pressure or high-temperature applications to prevent stress concentration and potential failure. 4. Lateral Tee: A lateral tee has one outlet at a 45-degree angle, allowing for a branch connection at a different direction. It is often used in situations where a pipeline needs to be diverted or connected at an angle. 5. Cross Tee: A cross tee has four outlets forming a cross-shaped configuration. It is used when there is a need to split or combine flow in multiple directions, commonly found in complex piping systems. 6. Unions and Socket Weld Tee: These types of tees have sockets or unions at the branch connection, allowing for easy disassembly and maintenance. They are often used in applications where regular inspection, cleaning, or replacement is required. 7. Threaded Tee: Threaded tees have threaded branch connections, which can be screwed onto the pipe without the need for welding. They are commonly used in low-pressure applications or when frequent disassembly is required. Each type of stainless steel pipe tee offers specific advantages and is selected based on the requirements of the particular piping system, such as flow rates, pressure, temperature, and compatibility with the fluids or gases being transported.

- Q: Can stainless steel pipes be insulated with polyacrylonitrile?

- Indeed, polyacrylonitrile (PAN) can be employed to insulate stainless steel pipes. PAN, a highly adaptable and widely utilized polymer, boasts exceptional thermal insulation capabilities. Thanks to its low thermal conductivity and resistance to heat transfer, PAN is frequently utilized as a foam or fiber insulation material. Applying PAN insulation to stainless steel pipes is a straightforward process that aids in minimizing heat loss or gain, enhancing energy efficiency, and averting condensation. Furthermore, it affords protection against corrosion and mechanical harm.

- Q: Can stainless steel pipes be painted?

- Indeed, it is possible to paint stainless steel pipes. Nevertheless, it should be taken into account that stainless steel is a non-porous substance with a sleek surface, posing difficulties for paint to adhere effectively. In order to achieve proper adhesion, it is advisable to diligently cleanse the surface and utilize a primer specially formulated for stainless steel. This will aid in creating a coarser texture on the surface, facilitating better bonding with the paint. Furthermore, opting for a superior, long-lasting paint suitable for metal surfaces will bolster the durability of the painted coating.

- Q: Stainless steel welded pipe or seamless pipe expensive?

- From the brand can understand: domestic grade Cr smaller numbers are more expensive, the sum of Cr after the larger the number the more expensive, more expensive Cr symbols and so on. Foreign steel also has some rules: such as the stainless steel, the same series of numbers of bigger, longer, more expensive and more letters.

- Q: Are stainless steel pipes suitable for petrochemical plants?

- Stainless steel pipes prove to be a highly suitable option for utilization in petrochemical plants. These plants handle substances that are highly corrosive, are subjected to extreme temperatures, and experience high pressure conditions. Consequently, employing materials that can withstand such harsh environments becomes crucial. With their exceptional corrosion resistance, stainless steel pipes are able to endure the corrosive nature of petrochemicals without deteriorating or compromising their structural integrity. Furthermore, stainless steel exhibits notable resistance to high temperatures, rendering it appropriate for the intense heat encountered in petrochemical processes. Additionally, these pipes possess outstanding mechanical properties, delivering the strength and durability necessary for applications involving high pressure within petrochemical plants. Moreover, stainless steel is a hygienic material that does not taint the substances being transported, thereby making it an ideal choice for maintaining the purity of petrochemicals. All in all, stainless steel pipes emerge as a dependable and preferred option for petrochemical plants due to their corrosion resistance, temperature resistance, mechanical properties, and hygienic nature.

- Q: Mirror stainless steel tube 60*60 how much is one meter?

- Stainless steel tube square weight formula: (pipe circumference / 3.14- actual thickness) * actual thickness *0.02491* length, 0.02491 of which is converted by the stainless steel density of a constant.

- Q: Are stainless steel pipes suitable for sanitary applications?

- Yes, stainless steel pipes are highly suitable for sanitary applications. They are corrosion-resistant, easy to clean, and have excellent hygienic properties, making them ideal for use in industries such as food and beverage, pharmaceuticals, and water treatment.

Send your message to us

Factory price 304L stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords