Wholesale 5052 3003 6061 pointer/lentil/orange peel patterned aluminum sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

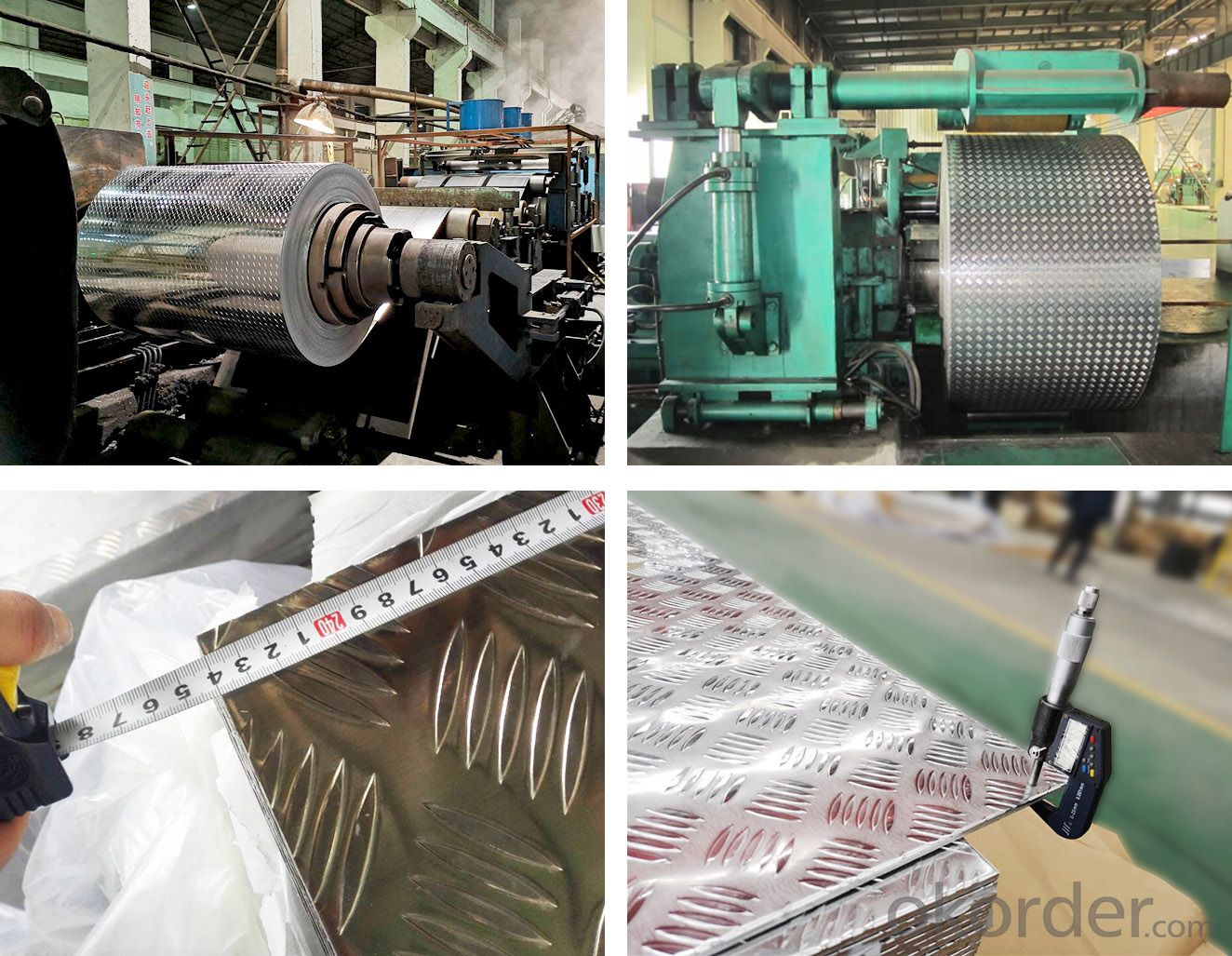

Patterned aluminum sheet is made of aluminum sheet through external mechanical processing. It is rolled on the basis of aluminum flat sheet with a roller press to form a convex pattern on the surface of the aluminum flat sheet. Common patterns of patterned aluminum sheet include one rib, two ribs, three ribs, five ribs, lentils, pointers, orange peel embossed aluminum sheet, etc.

Common alloys for patterned aluminum sheet: 1060, 3003, 5052, 5083, 6061 and other aluminum alloys

The use of patterned aluminum sheets is very extensive: ships, elevators, stairs, bloodless warehouses, floors, packaging, refrigerators, air conditioners, carriages, platforms, packaging pipes, display racks, a series of hanging beams, table legs, decorative strips, handles, wiring pipes and covers, chair tubes, etc.

Embossed aluminum sheet specifications:

| Alloy | 1060, 1060, 3003, 5052, 5083, 6061, etc |

| Thickness | 0.5-6mm, customizable |

| Width | 20-2650mm, customizable |

| Length | 100-16000mm, customizable |

| Technology | cold drawing, cold rolling, hot rolling, forging |

| Embossed pattern | lentil pattern, diamond pattern, five stripes, small five stripes, large five stripes, three stripes, one stripe, teardrop pattern, pointer pattern, orange peel pattern, etc., or customizable |

| Color | gold, red, black, silver, blue, rose gold, incense Colors such as benzene or customized |

| Coatings | PVDF, PE, etc |

| Packing | Internal: packed with plastic protective film to protect each piece |

| External | wrapped in waterproof kraft paper into bundles |

Advantages of aluminum patterned sheet:

1. Accurate size, good anti-slip effect, wide range of applications;

2. Strong plasticity, easy to form, excellent processing performance;

3. Embossed aluminum sheet can form a dense and solid oxide film on the aluminum surface to prevent the intrusion of oxygen, so it has good corrosion resistance;

4. Good elongation and tensile strength, fully able to meet normal processing requirements (stamping, stretching), high formability;

5. The surface quality of the patterned aluminum sheet is good, without oil spots, waves, scratches, roller marks, neat cutting edges, and no burrs.

What services can we provide?

Accepted delivery terms: FOB, CIF, CFR, CNF, EXW;

Accepted payment currencies: US dollars and RMB;

Accepted payment methods: T/T, L/C, MoneyGram, credit card, PayPal, Western Union;

- Q: What are the potential hazards or risks associated with the use and handling of aluminum sheets?

- <p>Safety issues related to aluminum sheets include the risk of cuts and lacerations from sharp edges, potential for eye injuries if aluminum particles or dust comes into contact with the eyes, and the risk of fire or explosion if aluminum dust is present in the air and ignited. Additionally, improper handling can lead to back injuries or other musculoskeletal disorders due to the weight of the sheets. Inhalation of aluminum dust over a long period may also pose health risks, although it's less common. It's crucial to use proper protective equipment and follow safety guidelines when working with aluminum sheets.</p>

- Q: Can aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a commonly used material in marine applications due to its excellent corrosion resistance properties and lightweight nature. It can withstand the harsh conditions of saltwater, making it suitable for boat building, marine structures, and other marine-related uses.

- Q: What are the different surface finishes for aluminum sheets in the aerospace industry?

- Aluminum sheets are widely used in the aerospace industry for constructing aircraft structures due to their lightweight and high strength. Various surface finishes can be applied to these sheets to enhance durability, protect against corrosion, and improve appearance. Anodizing is a commonly used finish that involves coating the aluminum with a protective oxide layer through electrolysis. This process not only improves corrosion resistance but also offers a range of color options and enhances adhesive acceptance. Another popular finish is alclad, which bonds a thin layer of pure aluminum to both sides of an alloy sheet. This provides excellent corrosion resistance and allows for better bonding with composite materials. Chemical conversion coatings are also used in the aerospace industry to provide corrosion resistance and improve paint adhesion. Mechanical finishes like grinding or brushing can be used for aesthetic purposes or to prepare the surface for further treatment. Specialized finishes are employed for specific applications. For areas with high wear resistance requirements, hard anodizing creates a durable surface. For parts needing low friction or high lubricity, a Teflon coating or dry film lubricant can be applied. The choice of surface finish for aluminum sheets in the aerospace industry depends on the specific application's requirements, including factors such as corrosion resistance, adhesion properties, wear resistance, and aesthetic preferences.

- Q: Aluminum plate thickness 3 mm, what is the allowable error in the national standard thickness?

- Length: + 1mmWidth: + 0.5mmThickness: + 0.02mm, that is, 2 filaments

- Q: has aluminum sheet reacted with concentrated sulfuric acid?

- it can be regarded as no reaction, concentrated sulfuric acid will make aluminum's surface inactivation,and produce a layer of dense aluminium oxide film which will prevent further reaction.

- Q: What is the surface hardness of aluminum sheets?

- The surface hardness of aluminum sheets can vary depending on the alloy and treatment, but generally, aluminum has a relatively low surface hardness compared to other metals.

- Q: Can aluminum sheet be used for automotive body panels?

- Yes, aluminum sheet can indeed be used for automotive body panels. Aluminum is a lightweight and corrosion-resistant material, making it desirable for improving fuel efficiency and increasing vehicle performance. It is widely used in the automotive industry to manufacture body panels, such as hoods, doors, fenders, and roofs, as it offers strength, durability, and design flexibility.

- Q: Explain the distinctions between aluminum and steel sheets in terms of their properties and applications.

- <p>Aluminum sheets and steel sheets differ in material composition, weight, strength, and applications. Aluminum sheets are lightweight, corrosion-resistant, and have good thermal conductivity, making them ideal for applications requiring light weight and resistance to corrosion. Steel sheets, on the other hand, are heavier, stronger, and more durable, suitable for structural applications where high strength is required. Steel is also magnetic, which aluminum is not, and has a higher melting point. However, steel is more prone to rust compared to aluminum, which requires protective coatings or treatments in many applications.</p>

- Q: Are 101 aluminum sheets suitable for solar panel frames?

- Yes, 101 aluminum sheets are generally suitable for solar panel frames due to their high strength-to-weight ratio, corrosion resistance, and ease of fabrication.

- Q: Are aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction. Aluminum is a lightweight yet strong material that offers excellent corrosion resistance in marine environments. It is commonly used in the construction of various marine vessels, including boats, ships, and yachts. One of the main advantages of using aluminum sheets in marine vessel construction is their high strength-to-weight ratio. This allows for the construction of lighter vessels, which can result in improved fuel efficiency, increased speed, and better handling. Additionally, the lightweight nature of aluminum makes it easier to transport and maneuver during the construction process. Another key benefit of aluminum sheets for marine vessel construction is their exceptional resistance to corrosion. Aluminum naturally forms a protective oxide layer on its surface, which prevents further oxidation and corrosion. This makes aluminum an ideal choice for marine environments, where vessels are constantly exposed to saltwater, humidity, and other corrosive elements. Furthermore, aluminum sheets can be easily fabricated and welded, providing flexibility in the design and construction of marine vessels. They can be shaped into various forms, allowing for the creation of complex hull structures and interior components. Aluminum also offers good thermal conductivity, which can help regulate temperature in the interior spaces of marine vessels. While aluminum sheets have many advantages for marine vessel construction, it is important to consider certain factors. Aluminum is susceptible to galvanic corrosion when it comes into contact with certain metals, such as steel or bronze. Therefore, proper insulation and anti-corrosion measures should be taken to prevent galvanic corrosion in aluminum-based vessels. In conclusion, aluminum sheets are highly suitable for marine vessel construction. Their lightweight, high strength-to-weight ratio, corrosion resistance, and ease of fabrication make them an ideal choice for building durable and efficient marine vessels. However, proper precautions should be taken to prevent galvanic corrosion when aluminum is used alongside other metals.

Send your message to us

Wholesale 5052 3003 6061 pointer/lentil/orange peel patterned aluminum sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords