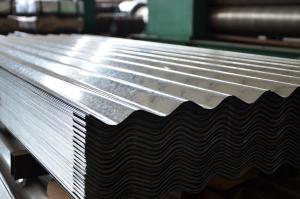

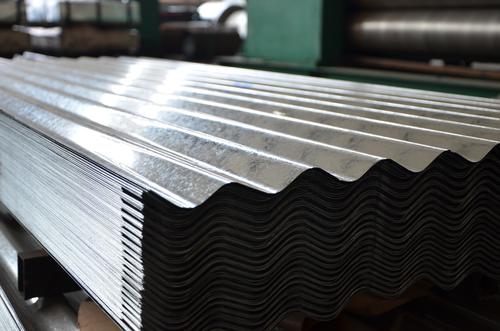

GALVANIZED CORRUGATION STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

GALVANIZED CORRUGATION STEEL SHEET

MATERIAL: FULL HARD, ZINC: 50G. CORRUGATION: 11NOS.

BUNDLE WEIGHT: 2-4MT, PACKAGE:SWAWORTHY PACKING

SIZE:0.18MM*900MM(1000 BEFORE)*3000

- Q: Are steel sheets suitable for food storage applications?

- Yes, steel sheets are highly suitable for food storage applications. They are durable, resistant to corrosion, and provide a hygienic and safe storage environment for food products. Steel sheets can maintain the freshness and quality of food while protecting it from external contaminants.

- Q: What are the different types of steel sheet finishes for marine applications?

- Marine applications commonly employ several different types of steel sheet finishes to enhance durability and corrosion resistance in the face of constant exposure to moisture, saltwater, and harsh weather conditions. 1. Hot-dip galvanized: Among the most frequently used finishes for marine applications is hot-dip galvanization. This process involves coating the steel sheet with a layer of zinc, effectively safeguarding against corrosion. The zinc layer acts as a sacrificial barrier, preventing rust formation in the underlying steel. 2. Stainless steel: Highly resistant to corrosion, stainless steel sheets find widespread use in marine applications. These sheets are composed of a steel, chromium, and nickel alloy, providing exceptional strength and corrosion resistance. Different grades of stainless steel sheets are available, with 316 stainless steel being the most commonly utilized in marine environments. 3. Powder coating: Powder coating is a favored finish for steel sheets in marine applications. The process involves electrostatically applying a layer of powdered polymer to the steel sheet, which is then cured under heat to form a robust and durable coating. Powder coating offers good corrosion resistance and can be tailored in terms of color and texture. 4. Epoxy coating: To ensure superior protection against corrosion in marine environments, steel sheets are frequently treated with epoxy coatings. These coatings boast chemical resistance and excellent adhesion to the steel surface. Epoxy coatings are also renowned for their high impact and abrasion resistance. 5. Organic coating: Organic coatings, such as polyurethane or acrylic coatings, are employed to shield steel sheets in marine applications. These coatings create a protective barrier against corrosion and are commonly utilized in offshore structures, ships, and other marine equipment. It is important to consider various factors, including specific environmental conditions, budget, and desired aesthetics, when selecting a steel sheet finish for marine applications. Consulting with a professional or referring to industry standards and recommendations can aid in determining the most suitable finish for a particular marine application.

- Q: What is the process of galvanizing steel sheets?

- The process of galvanizing steel sheets involves immersing them in a bath of molten zinc, which creates a protective coating on the surface of the steel. This coating prevents corrosion and extends the lifespan of the steel sheets.

- Q: What are the different thickness tolerances for steel sheets?

- The thickness tolerances for steel sheets can vary depending on the specific grade, manufacturing process, and industry standards. However, common thickness tolerances for steel sheets range from +/- 0.001 inches to +/- 0.010 inches, with tighter tolerances typically required for more precise applications.

- Q: What are the different types of finishes available for steel sheets?

- There are several different types of finishes available for steel sheets, each offering unique properties and aesthetic appeal. Some of the most common finishes include: 1. Mill Finish: This is the standard finish that is achieved after the steel sheet has been manufactured. It has a rough, dull appearance, typically with visible surface imperfections. 2. Hot Rolled Finish: This finish is achieved by subjecting the steel sheet to high temperatures during the manufacturing process, resulting in a scaly, rough surface. It is commonly used for structural applications where appearance is not a primary concern. 3. Cold Rolled Finish: This finish is achieved by cold rolling the steel sheet, which smooths out the surface and creates a clean, matte appearance. It is commonly used for applications that require a smooth and uniform surface, such as automotive panels or appliances. 4. Galvanized Finish: This finish is achieved by applying a layer of zinc to the steel sheet through a process called galvanization. It provides excellent corrosion resistance and is commonly used in outdoor applications, such as roofing or fencing. 5. Electroplated Finish: This finish is achieved by electroplating a thin layer of metal, such as chromium or nickel, onto the steel sheet. It provides enhanced corrosion resistance, improved aesthetics, and can be available in various colors. 6. Powder-Coated Finish: This finish involves applying a dry powder coating onto the steel sheet and then curing it with heat. It provides a durable and attractive finish, with various color options available. Powder coating also offers excellent corrosion resistance. 7. Brushed Finish: This finish is achieved by brushing the surface of the steel sheet with an abrasive material, creating a distinctive brushed pattern. It is commonly used for decorative applications, such as architectural elements or kitchen appliances. 8. Polished Finish: This finish involves polishing the steel sheet to create a smooth and reflective surface. It is commonly used for decorative applications that require a high level of aesthetics, such as ornamental pieces or jewelry. Overall, the choice of finish for steel sheets depends on the specific requirements of the application, including factors such as durability, corrosion resistance, aesthetics, and cost.

- Q: Are steel sheets suitable for exterior facade systems?

- Yes, steel sheets are suitable for exterior facade systems. Steel is a durable and resilient material that can withstand harsh weather conditions and provide structural stability. It is also highly customizable, allowing for various design options. Additionally, steel sheets offer fire resistance and low maintenance requirements, making them a popular choice for exterior facades.

- Q: Can the steel sheets be cut easily?

- With the correct tools and techniques, steel sheets can be easily cut. Despite its strength and durability, steel can still be cut through methods like shearing, sawing, or by utilizing plasma or laser cutting machines. The ease of cutting steel sheets is influenced by factors such as thickness and the particular type of steel employed. Generally, thinner sheets are more manageable to cut compared to thicker ones. Moreover, employing suitable cutting tools and adhering to safety precautions will guarantee a seamless and effective cutting process.

- Q: Are the steel sheets suitable for outdoor signage?

- Yes, steel sheets are suitable for outdoor signage. Steel is known for its strength, durability, and resistance to weather conditions. It can withstand harsh outdoor environments, including extreme temperatures, rain, wind, and sunlight, without warping or deteriorating. The thickness of steel sheets can be adjusted based on the size and design of the signage to ensure stability and longevity. Additionally, steel sheets can be easily customized and painted to match the desired aesthetic, making them a popular choice for outdoor signage projects.

- Q: Are steel sheets resistant to warping or bending?

- Steel sheets are generally known for their high tensile strength and stiffness, making them resistant to warping or bending. They are highly durable and can withstand heavy loads without deforming. However, it is important to consider that the thickness and quality of the steel sheet can affect its resistance to warping or bending. Thicker steel sheets tend to be more resistant compared to thinner ones. Additionally, factors like temperature changes and improper handling or installation can also impact the ability of steel sheets to resist warping or bending. Despite these factors, steel sheets are widely used in various industries due to their exceptional resistance to warping or bending.

- Q: Are steel sheets suitable for food processing applications?

- Yes, steel sheets are suitable for food processing applications. Steel is a durable and hygienic material that can withstand high temperatures, corrosion, and impact. It is commonly used in the food industry for equipment such as food preparation surfaces, storage containers, and processing machinery.

Send your message to us

GALVANIZED CORRUGATION STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords