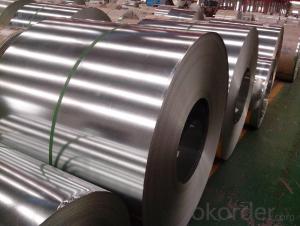

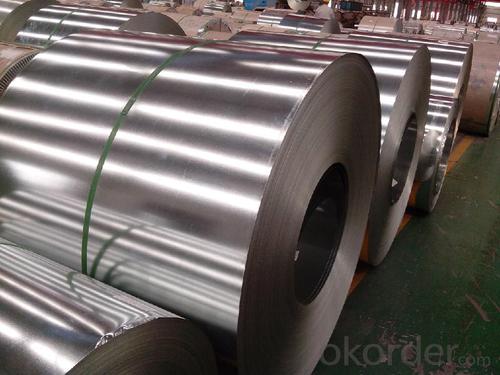

Hot Dip Galvanized Sheet,Gi Sheet,Competitive Galvanized Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time by bulk or container

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time with bulk or container

packing: Mill standard export packing in bundles/coil, around 2tons/bundle.

country of Origin: China

delivery Time: Within a 35 days

Shipment: by bulk vessel or by container

Leading goods:

section steel:angles,channels,I-beam,H-beam;

coils:cold/hot rolled coils,PPGI,galvanized coils,plate,checkered plate,cutting steel plate,steel strip;

wire rod:steel wire,deformed wire,bar;

pipe:seamless pipe,rectangular pipe,welded pipe,spiral welded pipe,pipe fittings;

stainless steel:steel sheets,stainless steel strips,stainless bar,stainless tube;

special:weathering steel,shipbuilding steel;

construction steel:C-channel,Z-channel,T-bar,high-speed divider plate,corrugated steel plate,steel grating.

Advantage:

We are the spot supplier, Six huge warehouses which can hold 20,000 MT goods.

It makes the cost lower than others,we can provide the competitive price for you.

Delivery time:

Normal sizes can be provided in 7days, the others should be ready in 30---45 days.

Further treatment:

We can offer cutting,painting,drilling holes,bending,threading, welding,galvanization,packing etc.

Security interest:

We have already passed the ISO9001, BV and SGS authentication which makes the quality secured.

If you have the interest in any of the products we can provided, pls don't hesitate to connect with me. Looking forward to cooperate with you.

FAQ of Steel Deformed Bar

1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

- Q: What are the common surface treatments for steel sheets?

- Common surface treatments for steel sheets include galvanizing, which involves applying a protective layer of zinc to prevent rusting; painting, which provides a decorative finish and additional corrosion resistance; and powder coating, which involves applying a dry powder to the surface and then curing it to create a durable, protective coating. Other treatments may include electroplating, chromating, or phosphating, depending on the specific requirements and intended use of the steel sheets.

- Q: Are steel sheets suitable for decorative applications?

- Yes, steel sheets are suitable for decorative applications. Steel sheets can be used in various decorative applications due to their versatility, durability, and aesthetic appeal. They can be easily manipulated into different shapes, sizes, and patterns, making them suitable for a wide range of decorative purposes. Steel sheets can be used to create decorative wall panels, room dividers, ceiling tiles, and facades. They can also be used for decorative accents such as trims, moldings, and decorative screens. The smooth and reflective surface of steel sheets adds a modern and elegant touch to any space. Additionally, steel sheets can be coated or treated with various finishes and coatings to enhance their decorative properties. These finishes can include paint, powder coating, patina, or even specialized coatings like faux rust or metallic finishes. These options allow for a wide range of design possibilities, enabling steel sheets to complement any interior or exterior décor style. Moreover, steel sheets are highly durable and long-lasting, making them suitable for both indoor and outdoor decorative applications. They are resistant to corrosion, fire, and extreme weather conditions, ensuring that the decorative elements made from steel sheets maintain their appearance and functionality over time. In summary, steel sheets are indeed suitable for decorative applications. Their versatility, durability, and aesthetic appeal make them an excellent choice for creating visually appealing and long-lasting decorative elements in various settings.

- Q: What is the process of polishing steel sheets?

- Achieving a smooth and shiny finish on steel sheets involves a series of steps. Firstly, the surface is cleaned to eliminate any dirt, oil, or debris, typically by employing a degreaser or solvent. Following this, abrasive materials like sandpaper or a sanding belt are utilized to sand the sheets, thus eliminating visible scratches and imperfections. Once sanded, a polishing compound or paste is usually applied and rubbed into the surface with a cloth or buffing wheel. This compound aids in removing any remaining scratches and revealing the natural shine of the steel. To further enhance the shine and smoothness, a finer polishing compound may be employed, repeating the process until the desired level of polish is achieved. Finally, the sheets are meticulously cleaned and inspected to ensure they meet the desired quality standards, including the removal of any remaining polishing compound residue and the identification of any remaining imperfections. In conclusion, the process of polishing steel sheets necessitates careful cleaning, sanding, and polishing to attain a smooth and shiny finish. The specific techniques and materials employed may vary depending on the desired level of polish and the type of steel being polished.

- Q: What is the difference between a brushed and polished steel sheet?

- A brushed steel sheet and a polished steel sheet differ in terms of their surface finishes. A brushed steel sheet is characterized by a pattern of parallel lines or scratches on its surface, created using abrasive materials or tools. The purpose of brushing is to give the steel sheet a textured appearance, which helps to hide fingerprints, scratches, and wear over time. It also provides a more industrial, matte finish. On the other hand, a polished steel sheet has a smooth and glossy surface. Polishing involves using polishing compounds or abrasive materials to remove imperfections, scratches, and oxidation from the steel surface. This process creates a reflective and mirror-like finish, enhancing the aesthetic appeal of the steel sheet. Polished steel sheets are commonly used in applications where appearance and visual appeal are important, such as architectural design, interior decoration, and high-end products. In summary, the main difference between a brushed and polished steel sheet lies in their surface finishes. Brushed steel sheets have a textured, matte appearance, while polished steel sheets have a smooth and glossy, mirror-like finish. The choice between the two depends on the desired aesthetic, functional requirements, and the intended application of the steel sheet.

- Q: Are the steel sheets resistant to warping or twisting?

- Yes, steel sheets are highly resistant to warping or twisting due to their inherent strength and rigidity.

- Q: Can steel sheets be used for artistic or sculptural projects?

- Yes, steel sheets can be used for artistic or sculptural projects. Steel sheets offer durability, strength, and versatility, making them a popular choice for artists and sculptors. They can be cut, shaped, welded, and manipulated to create various forms and designs, allowing artists to unleash their creativity and bring their visions to life. Additionally, steel sheets can be finished with different coatings or patinas to enhance their aesthetic appeal and protect them from corrosion.

- Q: Are the steel sheets suitable for food-grade applications?

- Yes, steel sheets are suitable for food-grade applications.

- Q: What is the difference between a galvanized and aluminized steel sheet?

- The durability and corrosion-resistant properties of galvanized steel and aluminized steel sheets make them widely used in various industries. However, there are notable distinctions between the two. Galvanized steel sheets have a layer of zinc coating that safeguards the underlying steel from rust and corrosion. This process, called galvanization, can be accomplished by immersing the steel sheet in a bath of molten zinc or by electroplating a zinc-rich coating. The zinc layer acts as a sacrificial barrier, meaning it will corrode before the steel, providing excellent rust protection. Galvanized steel finds common usage in outdoor applications like roofing, fences, and automobile parts. In contrast, aluminized steel sheets are coated with an aluminum-silicon alloy layer. This process, known as aluminization, involves immersing the steel sheet in a bath of molten aluminum or applying a thin layer of aluminum-silicon alloy through a continuous hot-dip process. The aluminum-silicon coating offers remarkable heat resistance and corrosion resistance. Aluminized steel is commonly employed in applications where high temperatures are present, such as automotive exhaust systems, heat exchangers, and ovens. To summarize, the primary distinction between galvanized and aluminized steel sheets lies in the type of coating applied to the steel. Galvanized steel is coated with zinc, providing outstanding rust protection, while aluminized steel is coated with an aluminum-silicon alloy, offering superior heat and corrosion resistance. The choice between the two depends on the specific requirements of the application, such as the presence of high temperatures or the need for long-lasting rust protection.

- Q: How do you clean and maintain steel sheets?

- To clean and maintain steel sheets, start by wiping them down with a damp cloth to remove any surface dirt or debris. For tougher stains, you can use a mild detergent or stainless steel cleaner, applied with a soft cloth or sponge. Always rinse the sheets thoroughly and dry them completely to prevent water spots or corrosion. To maintain the steel's shine, you can periodically apply a stainless steel polish or oil to protect against rust and enhance its appearance.

- Q: Are the steel sheets susceptible to rusting?

- Yes, steel sheets are susceptible to rusting. Rust is the result of a chemical reaction between iron, oxygen, and moisture. Since steel is primarily made of iron, it can easily corrode when exposed to air and water. However, the extent of rusting depends on various factors such as the type of steel, environmental conditions, and the presence of protective coatings. In order to prevent rusting, steel sheets are often coated with materials like zinc or paint to create a barrier between the steel surface and the surrounding environment. Regular maintenance and proper storage can also help minimize the risk of rust formation on steel sheets.

Send your message to us

Hot Dip Galvanized Sheet,Gi Sheet,Competitive Galvanized Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords