Cold rolled steel sheet hot sale in alibaba china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 61450 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc,

construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving,

containers, drums

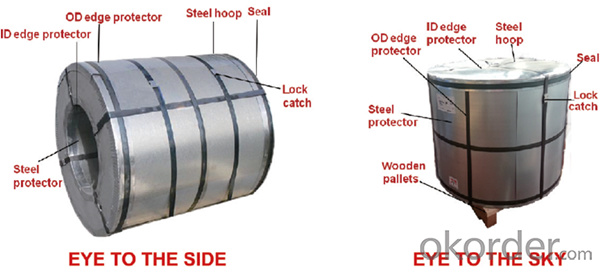

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q:What are the different manufacturing processes for steel sheets?

- Steel sheets can be manufactured through various processes, each with its own unique characteristics and applications. Some commonly used methods include: 1. The most widely employed technique is hot rolling, which involves heating the steel billet or slab to a high temperature and passing it through rollers to reduce its thickness. As a result, the sheets have a smooth surface and excellent mechanical properties. 2. Cold rolling, on the other hand, rolls the steel at room temperature, yielding sheets with higher dimensional accuracy and surface finish. This process is often employed to produce sheets with tight tolerances and improved surface quality. 3. Galvanizing is a process where steel sheets are coated with a layer of zinc to prevent corrosion. The sheets are either immersed in molten zinc or electroplated with it, forming a protective barrier that extends the steel's lifespan. 4. Coating processes can also be applied to steel sheets to enhance their properties or appearance. For instance, powder coating involves electrostatically applying a dry powder that is then cured under heat. Paint coating, on the other hand, entails applying a liquid paint to the surface and allowing it to dry. 5. Pickling, a chemical process, is employed to remove impurities like rust, scale, and oxides from the surface of steel sheets. Typically, the sheets are immersed in an acid bath that dissolves these unwanted materials, leaving behind a clean surface. 6. Once the steel sheets are manufactured, they can undergo cutting and forming operations. Laser cutting, plasma cutting, or shearing can be utilized to shape the sheets into desired sizes and shapes. Additionally, the sheets can be formed into various products using techniques like bending, deep drawing, or roll forming. These examples highlight the different manufacturing processes for steel sheets, and the choice of method depends on factors such as desired sheet properties, surface finish, and intended application.

- Q:How do steel sheets perform in electrical conductivity?

- Steel sheets have low electrical conductivity compared to other metals such as copper or aluminum.

- Q:How durable are steel sheets?

- Steel sheets are known for their exceptional durability. They are highly resistant to impact, corrosion, and extreme weather conditions, making them an ideal choice for various applications, including construction, automotive, and manufacturing industries. With proper maintenance, steel sheets can maintain their strength and integrity for decades, ensuring long-lasting performance and reliability.

- Q:What does "Z" mean to the performance of steel?

- To apply for Z steel plate thickness and subjected to tensile load on just the thickness direction has the performance requirements, it is in a certain level of structural steel (called parent steel) on the basis of the special treatment (such as calcium treatment, vacuum degassing, argon stirring etc.) and proper heat treatment steel.

- Q:What is the process of applying anti-slip coatings to steel sheets?

- The process of applying anti-slip coatings to steel sheets typically involves three main steps: surface preparation, application of the coating, and curing. First, the steel sheets are thoroughly cleaned and degreased to ensure proper adhesion of the coating. Then, a primer may be applied to further enhance adhesion. Next, the anti-slip coating is typically sprayed or rolled onto the steel sheets in multiple thin layers, ensuring even coverage. Finally, the coated sheets are left to cure, allowing the coating to fully bond and harden.

- Q:What is the average thickness of galvanized steel sheets?

- The average thickness of galvanized steel sheets typically ranges from 0.8mm to 3mm, depending on the specific application and industry standards.

- Q:What is the difference between coated and uncoated steel sheets?

- Coated and uncoated steel sheets differ primarily in terms of their protective layer and surface finish. Coated steel sheets, also known as galvanized steel sheets, are coated with a layer of zinc to prevent corrosion and increase durability. This zinc coating acts as a sacrificial layer, protecting the underlying steel from rust and other forms of damage. Additionally, coated steel sheets have a smoother and more polished appearance. On the other hand, uncoated steel sheets are not treated with any protective layer. This makes them more susceptible to corrosion, especially when exposed to moisture or chemicals. Uncoated steel sheets are often used in applications where corrosion resistance is not a significant concern, such as in construction projects where the steel will be covered or protected in some way. In terms of cost, coated steel sheets are generally more expensive than uncoated steel sheets due to the additional manufacturing process involved in applying the zinc coating. However, the added cost is justified by the enhanced durability and extended lifespan of coated steel sheets. In summary, the main difference between coated and uncoated steel sheets lies in the presence of a protective layer. Coated steel sheets offer superior corrosion resistance and have a smoother appearance, while uncoated steel sheets are more vulnerable to corrosion and have a rougher surface finish.

- Q:What is the tensile strength of a steel sheet?

- The tensile strength of a steel sheet generally ranges from 370 to 700 megapascals (MPa), depending on the specific type of steel and its thickness.

- Q:How do steel sheets perform in terms of vibration resistance?

- Steel sheets have excellent vibration resistance due to their high stiffness and density. The rigidity of steel enables it to dampen vibrations effectively, making it a reliable choice for applications where vibration control is crucial.

- Q:What factors affect the cost of steel sheets?

- Several factors affect the cost of steel sheets, including the current market demand and supply, raw material prices, manufacturing and processing costs, transportation and logistics expenses, as well as any applicable trade tariffs or taxes. Additionally, factors such as the type and quality of steel, size and thickness of the sheets, as well as any special finishes or coatings required, can also impact the overall cost.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold rolled steel sheet hot sale in alibaba china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 61450 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords