AISI 4140 42CrMo4 Alloy Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

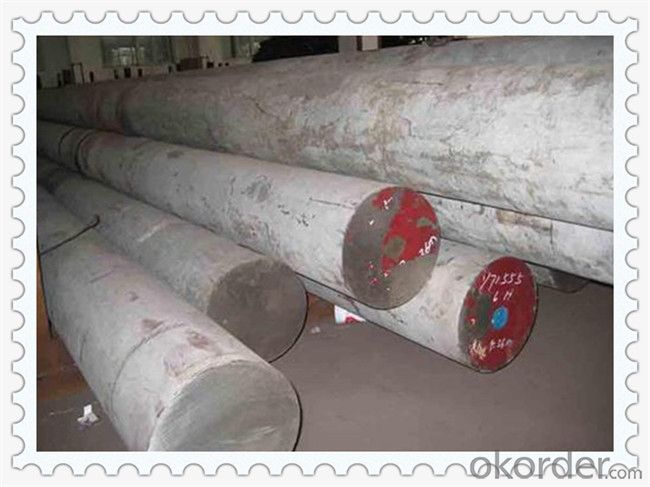

AISI 4140 42CrMo4 Alloy Steel Round Bar

Specifications

1. Delivery condition: Hot-rolled,black surface

2. Chemical composition: C:0.38~0.45 Si:≤0.40 Mn:0.60~0.90 S:≤0.035 P:≤0.035 Cr:0.90~1.20 Ni:≤0.030 Cu:≤0.030 Mo:0.15~0.30

C | Si | Mn | P | S | Cr | Mo |

0.38-0.45 | ≤0.4 | 0.6-0.9 | ≤0.035 | ≤0.030 | 0.9-1.2 | 0.15-0.30 |

3.Process: EAF + LF + VD + Forged + Heat Treatment (optional)

4.Delivery condition: Hot forged +Rough machined (black surface after Q/T)+ Turned (optional)

5.Technical Data: According to the customer's requirement of Chemical Composition, Physical Properties and Mechanical Testing

6.Test: ultrasonic test according to SEP 1921-84 3 D/D

7. Material details will be as per agreed technical specifications

Equipment

We are well-equipped with 2000-Ton Hydraulic press, 15-Ton Hydraulic manipulator, various kinds of Lathe and boring machine, product range OD 200mm-800mm, Length less than 9m.

Products

- Q: What are the advantages of using nickel-titanium alloy steel round bars?

- There are several advantages of using nickel-titanium (NiTi) alloy steel round bars. First and foremost, NiTi alloy steel round bars exhibit exceptional shape memory and superelasticity properties. This means that they can be deformed or bent, and then return to their original shape upon heating or removal of stress. This unique characteristic makes NiTi alloy steel round bars ideal for applications where flexibility and resilience are required, such as in the medical field for surgical instruments or orthodontic wires. Another advantage of using NiTi alloy steel round bars is their high corrosion resistance. Nickel and titanium are both highly resistant to corrosion, making the alloy extremely durable and long-lasting. This makes them suitable for various industrial applications, including marine environments, where exposure to moisture and saltwater can lead to corrosion of other metals. Additionally, NiTi alloy steel round bars have a high strength-to-weight ratio. Despite being lightweight, they possess excellent mechanical properties, including high tensile strength and good fatigue resistance. This makes them suitable for various engineering and structural applications, such as in aerospace, automotive, and construction industries. The lightweight nature of the bars also allows for easier handling and transportation. Furthermore, NiTi alloy steel round bars have excellent thermal stability, with a wide temperature range of usability. They can withstand extreme temperatures without losing their shape memory or superelasticity properties. This makes them suitable for applications that involve exposure to high or low temperatures, such as in aerospace or oil and gas industries. In summary, the advantages of using nickel-titanium alloy steel round bars include their shape memory and superelasticity properties, high corrosion resistance, high strength-to-weight ratio, and excellent thermal stability. These qualities make NiTi alloy steel round bars a versatile and reliable choice for a wide range of applications across various industries.

- Q: How are steel round bars used in the manufacturing of agricultural implements?

- Steel round bars are commonly used in the manufacturing of agricultural implements due to their strength and durability. These bars are used as a primary material for constructing various components of agricultural tools such as plows, cultivators, tillers, and harrows. The high tensile strength of steel round bars allows these implements to withstand the rigorous demands of agricultural operations, ensuring long-lasting performance and efficient use in the field.

- Q: What are the different types of steel round bar alloys used in the aerospace industry?

- There are several different types of steel round bar alloys that are commonly used in the aerospace industry. These alloys are specifically designed to meet the demanding requirements of the aerospace sector, including high strength, corrosion resistance, and lightweight properties. 1. Stainless Steel: Stainless steel is one of the most popular alloys used in aerospace applications. It offers excellent corrosion resistance, high strength, and good heat resistance. This alloy is commonly used in aircraft components such as landing gear, fasteners, and engine parts. 2. Titanium Alloy: Titanium alloys are widely used in the aerospace industry due to their high strength-to-weight ratio. They offer excellent corrosion resistance, good fatigue strength, and can withstand high temperatures. Titanium alloys are commonly used in aircraft frames, engine components, and landing gear. 3. Aluminum Alloy: Aluminum alloys are lightweight and have good mechanical properties, making them suitable for aerospace applications. They offer good corrosion resistance and are often used in aircraft structures, wings, and fuselage components. 4. Nickel Alloy: Nickel alloys are known for their high strength and excellent resistance to extreme temperatures. They are commonly used in aerospace applications where resistance to heat, wear, and corrosion is critical, such as in turbine engines and exhaust systems. 5. High-Strength Low-Alloy (HSLA) Steel: HSLA steels are known for their high strength and good weldability. They offer good toughness and impact resistance, making them suitable for aerospace applications where strength and durability are essential, such as in landing gear and structural components. Overall, the aerospace industry utilizes a combination of these steel round bar alloys to meet the specific requirements of different components and applications. Each alloy offers unique properties that make it suitable for specific aerospace applications, ensuring the safety, reliability, and performance of aircraft in the highly demanding aerospace environment.

- Q: Are steel round bars suitable for high-stress applications?

- Steel round bars are well-suited for high-stress situations due to their strength and durability. The remarkable properties of steel, including its strength and durability, make it a perfect material for environments with high levels of stress. In particular, round bars offer excellent tensile strength and can withstand heavy loads and intense pressure. They are widely used in industries like construction, manufacturing, and engineering, where reliable and robust materials are needed for high-stress applications. The round shape of the bars also ensures consistent strength, guaranteeing dependable performance even in extreme conditions. Moreover, steel round bars can be heat-treated to enhance their mechanical properties, making them even more suitable for high-stress situations. In summary, steel round bars are a dependable and efficient choice for demanding environments that require exceptional strength and resilience.

- Q: What are the different types of steel round bars used in the automotive suspension systems?

- There are several different types of steel round bars used in automotive suspension systems, each offering unique properties and advantages. 1. Carbon steel round bars: These are the most commonly used type of steel round bars in automotive suspension systems. They offer good strength and durability, making them ideal for handling the weight and stress of the vehicle. Carbon steel round bars also have excellent machinability, allowing for easy fabrication and customization. 2. Alloy steel round bars: Alloy steel round bars are made by adding various alloying elements such as chromium, nickel, or molybdenum to carbon steel. This enhances their mechanical properties, including increased strength, hardness, and wear resistance. In automotive suspension systems, alloy steel round bars are often used in critical components such as control arms or sway bars. 3. Stainless steel round bars: Stainless steel round bars are known for their corrosion resistance and aesthetic appeal. While not as common in automotive suspension systems, they can be used in certain applications where resistance to rust or chemical exposure is necessary. Stainless steel round bars also offer good strength and high temperature resistance, making them suitable for specific suspension components. 4. High-strength steel round bars: As the name suggests, high-strength steel round bars are designed to provide exceptional strength and toughness. These bars are often used in demanding suspension applications, such as heavy-duty trucks or performance vehicles, which require increased load-bearing capacity and improved resistance to fatigue. 5. Forged steel round bars: Forged steel round bars are known for their exceptional strength and structural integrity. They are created by heating the steel to a high temperature and then shaping it under extreme pressure. This manufacturing process results in a dense and uniform structure, making forged steel round bars highly reliable and suitable for rigorous suspension systems. In summary, the different types of steel round bars used in automotive suspension systems include carbon steel, alloy steel, stainless steel, high-strength steel, and forged steel. Each type offers specific properties and advantages that cater to the unique requirements of suspension components in various vehicles.

- Q: Can steel round bars be used for making wire?

- Yes, steel round bars can be used for making wire. Steel round bars can be processed into wire by a process called wire drawing. In this process, the steel round bar is pulled through a series of progressively smaller dies to reduce its diameter until it reaches the desired wire size. This process is commonly used in the manufacturing of various types of wire, including steel wire used in construction, electrical wiring, fencing, and other applications. The steel round bars used for making wire are typically made from carbon steel, which provides the necessary strength and durability for the wire to be used in various applications.

- Q: How do you calculate the weight of a steel round bar based on its density and dimensions?

- To calculate the weight of a steel round bar, you need to multiply its density by its volume. The volume of a round bar can be calculated using the formula V = πr^2h, where r is the radius and h is the height. Once you have the volume, simply multiply it by the density of the steel to get the weight.

- Q: What is the tensile strength of a steel round bar?

- The tensile strength of a steel round bar is influenced by a range of factors, including the grade of steel, the manufacturing process, and any additional treatments or coatings applied. Typically, steel round bars exhibit high tensile strength due to their composition and structural design. The specific tensile strength can vary significantly based on the grade of steel. For instance, low carbon steel generally has a tensile strength ranging from 400 to 550 MPa (megapascals), while high carbon steel can have a tensile strength of 700 to 1000 MPa or even higher. It should be noted that heat treatment processes like quenching and tempering can further enhance the tensile strength of a steel round bar, resulting in increased strength and hardness. Additionally, the addition of certain alloying elements such as chromium, nickel, and molybdenum can improve the tensile strength and other mechanical properties of steel. To accurately determine the precise tensile strength of a specific steel round bar, it is essential to refer to the manufacturer's specifications or consult relevant industry standards like ASTM or AISI standards. These standards offer comprehensive information on the mechanical properties, including tensile strength, for different steel grades.

- Q: What are the different types of steel round bar surface treatments used in the automotive industry?

- In order to enhance the performance, durability, and aesthetics of components in the automotive industry, various surface treatments are utilized for steel round bars. Some commonly employed treatments include: 1. Phosphating: Widely used, this treatment involves the application of a phosphate coating onto the steel round bar. Its purpose is to improve corrosion resistance and establish a suitable foundation for further coatings or paints. 2. Galvanizing: Another method is to apply a layer of zinc onto the surface of the steel round bar. This treatment offers excellent corrosion resistance and extends the lifespan of the component. 3. Electroplating: By utilizing an electric current, a thin layer of metal, such as chrome or nickel, is deposited onto the steel round bar's surface. This treatment enhances appearance, provides corrosion resistance, and improves wear resistance. 4. Powder coating: A popular technique involves the application of a dry powder onto the surface of the steel round bar, followed by heating to form a protective coating. This treatment ensures exceptional durability, corrosion resistance, and can be customized with different colors and finishes. 5. Anodizing: Typically used for aluminum components, anodizing can also be applied to steel round bars in specific cases. This treatment involves the creation of an oxide layer on the surface, resulting in improved corrosion resistance and enhanced appearance. 6. Black oxide coating: A chemical treatment that produces a blackened surface on the steel round bar. This treatment offers corrosion resistance, improved aesthetics, and can serve as a lubricant in certain applications. It is crucial to consider the specific requirements of the automotive component, including environmental conditions, desired appearance, and functional properties when selecting the appropriate surface treatment. Manufacturers meticulously choose the most suitable treatment to ensure optimal performance and longevity of steel round bars in the automotive industry.

- Q: Can steel round bars be used in the manufacturing of valves?

- Yes, steel round bars can be used in the manufacturing of valves. Steel round bars are commonly used in valve manufacturing due to their high strength, durability, and corrosion resistance. The round bars can be machined and forged into various valve components such as stems, bodies, and discs. Steel round bars also provide excellent mechanical properties, ensuring the valves can withstand high pressure and temperature conditions. Additionally, steel round bars can be easily welded or threaded to connect different valve parts together. Overall, steel round bars are a reliable and popular material choice for valve manufacturing.

Send your message to us

AISI 4140 42CrMo4 Alloy Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords