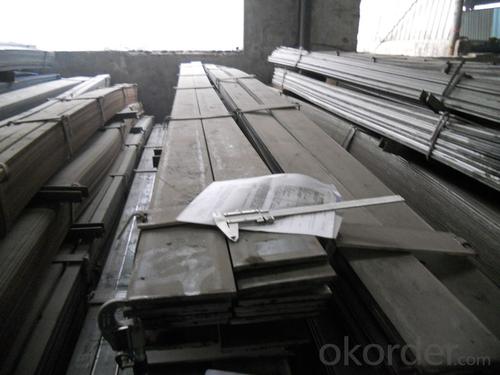

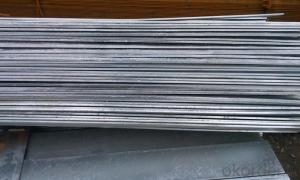

Wholesale hot rolled steel flat bar with lowest price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1passed the ISO9001:2000

2steel manufacturer,30 years experience

3near the seaport ,low cost

4good reputation and service

Carbon steelsdo rust easily, but they can be easily painted or primed. They are cheap so they are the normal choice for most

fabrications. Mild Steel can be easily cut or drilled to meet your requests.

Mild Steel Flat Bar is generally used for fabrication, frameworks and for structural items. Such as:

Plastic moulds, cold work die and mould base as well as constructional part .

Automobile manufacturing( Auto girders special steel

Shipping manufacture

Railway special pad

Mechanical steel

section size: axb=(650-580)x(6-50)

lenght : 6m/9m/12m or as required

Chemical composition of Q235

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Physical properties of Q235

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: How do you join steel flat bars together?

- One common method to join steel flat bars together is through welding. This involves melting the edges of the bars and fusing them together using a welding electrode or filler metal. Another option is to use mechanical fasteners such as bolts, screws, or rivets to connect the flat bars. Additionally, steel flat bars can be joined using adhesives specifically designed for metal bonding. The choice of joining method depends on the specific application and desired strength of the connection.

- Q: What are the common applications of steel flat bars?

- Steel flat bars are commonly used in a variety of applications including construction, manufacturing, and transportation industries. They are often used as structural support in buildings, fabrication of machinery and equipment, and as base plates or brackets in various manufacturing processes. Additionally, steel flat bars are frequently used in the automotive and aerospace industries for their strength and durability.

- Q: Can steel flat bars be used for reinforcement in concrete structures?

- Yes, steel flat bars can be used for reinforcement in concrete structures. They are commonly used as reinforcement elements to enhance the strength and durability of concrete structures, such as beams, columns, and slabs. The flat bars are placed within the concrete to provide additional tensile strength, prevent cracking, and increase structural integrity.

- Q: Can steel flat bars be used in the aerospace industry?

- Indeed, in the aerospace industry, steel flat bars find ample application. Steel, owing to its exceptional strength, durability, and versatility, is extensively employed across diverse sectors, including aerospace. In the construction of aircraft frames, wings, landing gears, and other structural elements, steel flat bars prove invaluable. They establish a robust and dependable support system, assuring the aircraft's structural integrity and safety. Moreover, these bars can be skillfully machined and fabricated to cater to the precise demands and performance benchmarks of the aerospace industry.

- Q: What are the common safety precautions when working with steel flat bars?

- To ensure the safety of workers while working with steel flat bars, it is necessary to adhere to several common safety precautions. Firstly, it is of utmost importance to wear appropriate Personal Protective Equipment (PPE). This entails wearing safety glasses or goggles to protect the eyes from flying debris or sparks, gloves to safeguard hands from sharp edges, and steel-toe boots to shield feet from heavy objects or falling materials. Secondly, it is crucial to employ proper lifting techniques to avoid back or muscle injuries, given the weight of steel flat bars. Lifting should be done using the legs rather than the back, and any twisting or jerking movements during lifting should be avoided. Moreover, when not in use, steel flat bars should be stored securely and in an organized manner to prevent tripping or falling hazards. Furthermore, heavy bars should be stored at a lower height to minimize the risk of injuries caused by falling objects. Additionally, cautious handling is vital when working with steel flat bars, particularly due to the presence of sharp edges and corners. Workers should always be aware of their surroundings and refrain from sudden movements that may result in injury. When necessary, proper lifting equipment such as lifting clamps or tongs should be utilized to ensure a secure grip on the bars. Furthermore, fire safety measures must be implemented as steel flat bars can produce sparks during cutting or welding. It is essential to have a fire extinguisher nearby and ensure adequate ventilation in the workspace to prevent the accumulation of flammable gases or fumes. In order to ensure comprehensive safety, all workers should receive appropriate training and education on the handling and use of steel flat bars. This includes understanding the correct tools and equipment to use, as well as being aware of the potential hazards associated with working with steel flat bars. By adhering to these common safety precautions, the risk of accidents and injuries can be minimized, thereby creating a safe working environment for those working with steel flat bars.

- Q: Can steel flat bars be used for electrical or grounding applications?

- No, steel flat bars are not typically used for electrical or grounding applications. Copper or aluminum are the preferred materials for such purposes, as they offer better conductivity and are less prone to corrosion.

- Q: Are steel flat bars suitable for making storage racks?

- Yes, steel flat bars are suitable for making storage racks. Steel flat bars are known for their strength, durability, and versatility, making them an ideal choice for constructing storage racks. They have a high load-bearing capacity, allowing them to safely hold and support heavy objects. Additionally, steel flat bars are resistant to bending and warping, ensuring the longevity of the storage racks. They are also easy to work with and can be welded or bolted together to create custom-sized racks that meet specific storage needs. Overall, steel flat bars provide a reliable and sturdy framework for storage racks, making them a popular choice in various industries and settings.

- Q: What are the different methods of finishing the edges of steel flat bars?

- There are several methods of finishing the edges of steel flat bars, each with their own advantages and applications. 1. Cutting: One of the simplest methods is cutting the edges of the flat bar to the desired length or shape. This can be done using various cutting tools such as shears, saws, or plasma torches, depending on the thickness and hardness of the steel. Cutting provides a clean and precise finish, making it suitable for most applications. 2. Grinding: Grinding the edges of steel flat bars helps achieve a smooth and polished finish. This process involves using a grinding wheel or belt sander to remove any rough edges or burrs, resulting in a clean and professional look. Grinding is commonly used for decorative purposes or when a smooth surface is required. 3. Deburring: Deburring is a process that removes the burrs or sharp edges left after cutting or grinding. This can be done manually using a file or deburring tool, or by employing a vibratory or tumbling machine. Deburring ensures safety and improves the overall appearance of the flat bar. 4. Beveling: Beveling refers to the process of creating angled edges on the flat bar. This is often done to enhance weldability or to create a chamfered edge for aesthetic purposes. Beveling can be achieved using specialized tools like beveling machines or by hand with a grinder. 5. Galvanizing: Galvanizing is a process that involves coating the steel flat bar with a layer of zinc to protect it from corrosion. This method is commonly used in applications where the flat bar will be exposed to harsh environmental conditions or moisture. Galvanizing not only provides a protective coating but also gives the flat bar a shiny and attractive finish. 6. Powder Coating: Powder coating is a technique where a dry powder is applied to the steel flat bar and then cured under heat to form a protective and decorative layer. This method offers a wide range of colors and finishes, making it ideal for applications where aesthetics are important, such as furniture or architectural elements. 7. Anodizing: Anodizing is primarily used for aluminum, but it can also be applied to steel flat bars to provide corrosion resistance and improve the surface finish. This process involves creating an oxide layer on the steel's surface through an electrochemical reaction. Anodized steel flat bars are commonly used in the construction and automotive industries. In conclusion, the different methods of finishing the edges of steel flat bars include cutting, grinding, deburring, beveling, galvanizing, powder coating, and anodizing. Each method offers unique benefits and is chosen based on the desired functionality, appearance, and durability required for the specific application.

- Q: -40x4 hot galvanized flat steel, a water 1m, what do you mean?

- This is an auxiliary grounding electrode lead, if the main body foundation has reached the design resistance of less than 4 ohms, can not be auxiliary grounding electrode.

- Q: How do you protect steel flat bars from weathering?

- One way to protect steel flat bars from weathering is by applying a protective coating such as paint or a rust-resistant finish. Additionally, storing the bars in a dry and well-ventilated area or using covers can help prevent moisture exposure and minimize the risk of corrosion. Regular inspection, cleaning, and maintenance can also contribute to the long-term protection of steel flat bars from weathering.

Send your message to us

Wholesale hot rolled steel flat bar with lowest price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords