High Quality Small Five Bars Aluminum Patio Cover Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Small Five Bars Aluminium Sheets with High Quality

Small five bars aluminum sheets are widely used in decorative purchase in construction, packing and appliance. They are also very popularly used in anti-slippery purchase in vehicles and public places.

Small five bars aluminum sheets are with high quality. They are good at ductility, heat conductivity, anti-corrosion and moisture resistance.

Our aluminum sheets can meet the highest standards its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

2.Main Features of Small Five Bars Aluminium Sheets with High Quality

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

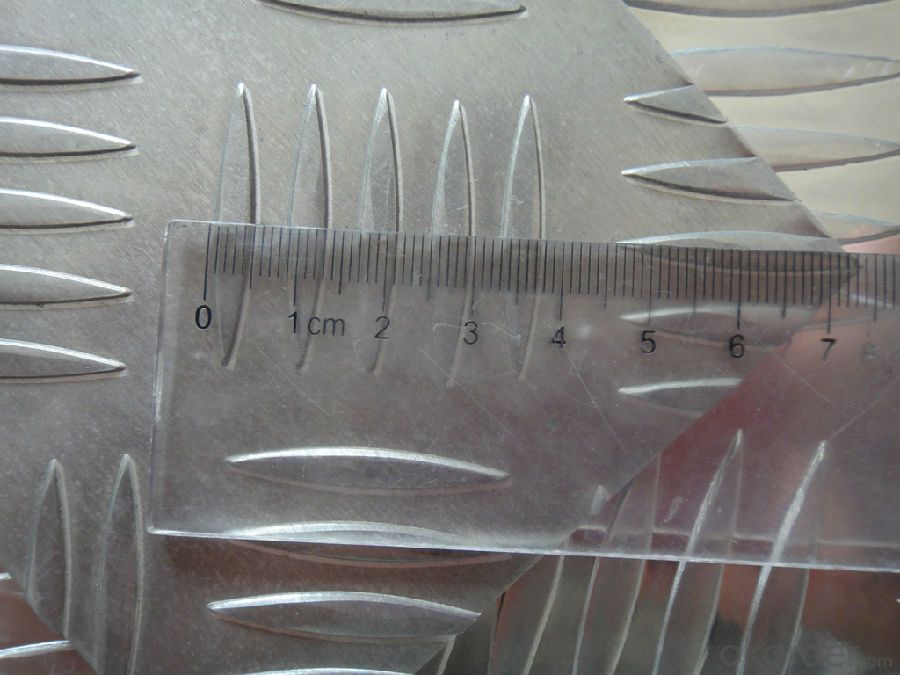

3. Small Five Bars Aluminium Sheets with High Quality Images

4.Specification of Small Five Bars Aluminium Sheets with High Quality

Alloy: AA1050, AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5052

Temper: H14, H18, H24, H26, H32

Thickness: 0.2-20mm

Width:10mm- 1500mm

Embossed patterns: big five bars

Standard: GB/T3880-2006, ASTM, ISO, EU standard

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: This question is asking for a list of different types of fasteners that can be used to attach aluminum sheets to a structure.

- <p>There are several types of fasteners used for attaching aluminum sheets to a structure, including: 1. Rivets: These are permanent fasteners that join two pieces by deforming the rivet material. 2. Screws: These are threaded fasteners that can be inserted and removed as needed. 3. Bolts: Similar to screws, bolts are used with nuts to secure aluminum sheets. 4. Adhesives: Chemical adhesives can be used for bonding aluminum sheets without visible fasteners. 5. Welding: Although not a fastener, welding can join aluminum sheets permanently. 6. Clips and Clamps: These are used for temporary or non-structural attachment. 7. Self-tapping screws: These screws create their own threads in the material being fastened. Each type has its own advantages and is chosen based on the specific requirements of the project.</p>

- Q: Are the aluminum sheets suitable for manufacturing aircraft fuselages?

- Yes, aluminum sheets are suitable for manufacturing aircraft fuselages. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and easy formability. It provides structural integrity while keeping the weight of the fuselage low, making it an ideal material choice for aircraft manufacturing.

- Q: can the oxide film on the surface of aluminum sheet prevent the erosion of acid liquid? Why?

- yes, acid can react with aluminum oxide , generating salt and water, but its anti-corrosion will be stronger if oxide film on the surface is enough dense.

- Q: Do 101 aluminum sheets have any specific certifications or standards?

- Yes, 101 aluminum sheets typically have certifications and standards that ensure their quality and performance. These may include certifications like ASTM (American Society for Testing and Materials) and standards such as AA (Aluminum Association) standards, which verify the material's composition, mechanical properties, and manufacturing processes. Additionally, specific industry certifications like ISO 9001 (International Organization for Standardization) may be applicable to ensure consistent quality control during production.

- Q: Can the aluminum sheets be used for manufacturing architectural sunshades?

- Yes, aluminum sheets can be used for manufacturing architectural sunshades. Aluminum is a popular material choice for sunshades due to its lightweight nature, durability, and resistance to corrosion. It can be easily fabricated into different shapes and sizes, allowing for flexibility in design. Additionally, aluminum has excellent heat reflectivity properties, making it effective in reducing solar heat gain and providing shade to buildings. Overall, aluminum sheets are a suitable material for manufacturing architectural sunshades.

- Q: how to separate the aluminum sheet in plastic?

- Put them into clean water if both of them won’t react with water, and aluminum sheet will sink into the bottle, then fish up them separately.

- Q: What is the standard size of an aluminum sheet?

- The standard size of an aluminum sheet can vary depending on the specific application and industry. However, in general, aluminum sheets are commonly available in standard sizes of 4 feet by 8 feet or 48 inches by 96 inches. These dimensions are widely used in construction, manufacturing, and other industries due to their versatility and compatibility with standard equipment and processes. However, it's important to note that aluminum sheets can also be custom cut or ordered in different sizes to meet specific project requirements.

- Q: I put the aluminum in copper chloride for an experiment and i was wondering if they had different properites.

- Aluminium is and element. An oxide is the result of a substance reacting with oxygen. The properties are completely different for elements and oxides.

- Q: is steel better for making bicycle frames.....how does it differ from the aluminum framed bikes?

- It depends on the type of riding you do. If you ride long distance you don't want aluminum, it is very stiff and will wear out your body with jolts from the road. Steel provides some degree of flex, which softens road jolts. You might want to go to a bike shop and hold a steel bike and alum bike so you can appreciate the difference in weight. Another thing about alum bikes is they do suffer from metal fatigue, so they will not last for 20 years like a steel bike (perhaps even much less depending on usage).

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays. Aluminum naturally forms a protective oxide layer that acts as a barrier against UV radiation. This oxide layer helps to prevent the aluminum sheet from being damaged or degraded by exposure to the sun's UV rays. This makes aluminum sheet a suitable material for outdoor applications, where it can withstand prolonged exposure to sunlight without fading or deteriorating. Additionally, the reflective properties of aluminum further contribute to its UV resistance, as it can reflect a significant amount of the sun's rays, reducing heat absorption and potential damage.

Send your message to us

High Quality Small Five Bars Aluminum Patio Cover Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords