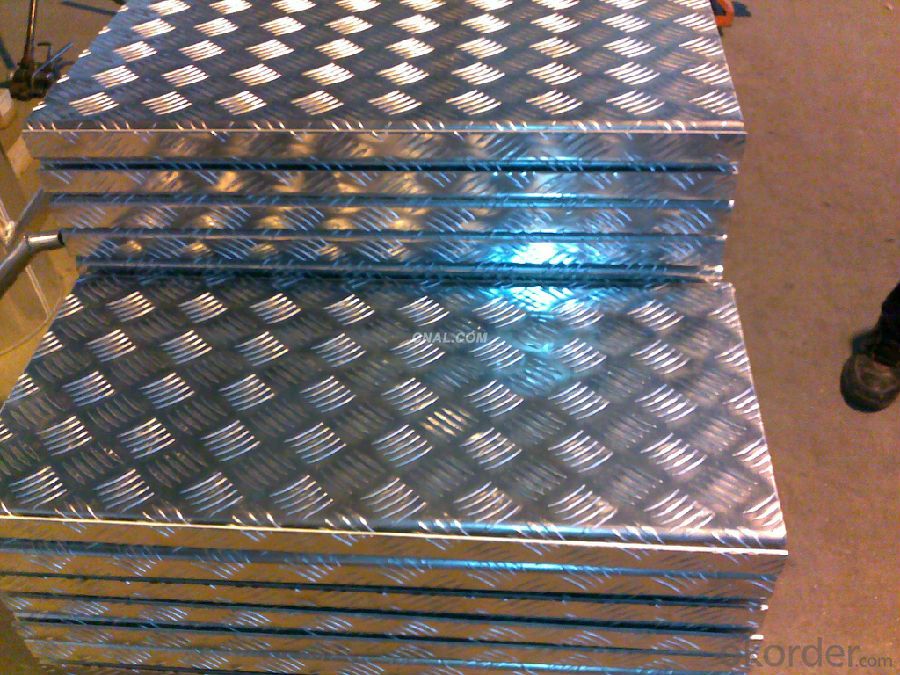

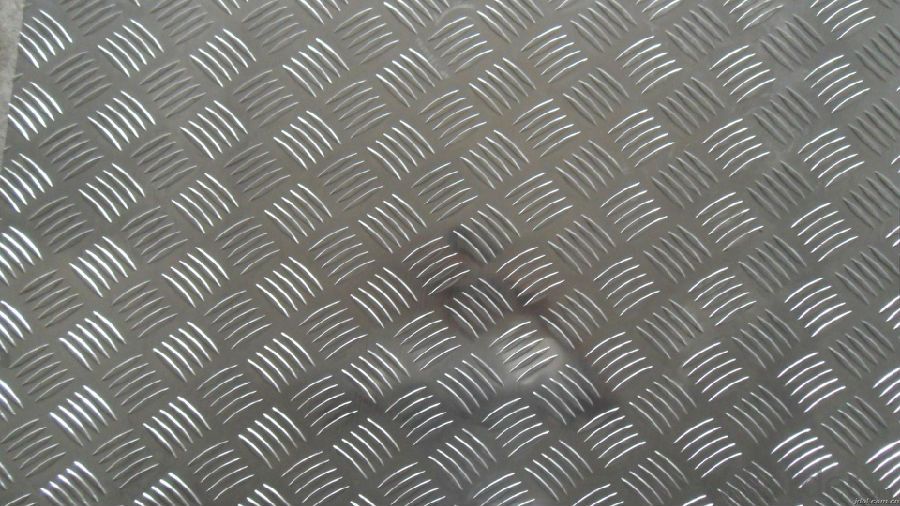

Aluminium FIve Bars for Skid Resistance Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminium FIve Bars for Skid Resistance Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium FIve Bars for Skid Resistance Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium FIve Bars for Skid Resistance Application:

Aluminium FIve Bars for Skid Resistance Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium FIve Bars for Skid Resistance Application:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:I've heard twice in the past 2 days on ESPN that they think Aluminum bats are dangerous. I disagree with this cause if they were dangerous why would they allow them to use them in college and high school. Isnt that what the BESR certification mean that the bat is safe that the ball isnt going to come off at super high speeds. i just wanted to get your opinion.

- in my opinion, when people make an argument about how aluminum bats are dangerous i cant help to imagine a cracked wooden bat flying thru the infield. I think that wooden bats are actually more dangerous. a lot of people that don't like aluminum bats say that one day a fly ball is gonna kill someone off of a aluminum bat, but the same thing would probably happen woth a wooden bat. i personally love to use aluminum bats and a hate it when my high school coach makes me use a wooden bat.

- Q:Is aluminum sheet recyclable?

- Yes, aluminum sheet is highly recyclable. Aluminum is one of the most sustainable and environmentally friendly materials, as it can be recycled indefinitely without losing its quality. The recycling process of aluminum sheet involves melting it down to its liquid form, which requires significantly less energy compared to the production of primary aluminum from raw materials. Recycling aluminum sheet not only conserves natural resources but also reduces greenhouse gas emissions and saves energy. It is estimated that recycling one ton of aluminum sheet saves about nine tons of CO2 emissions. Therefore, aluminum sheet recycling is not only economically viable but also an essential practice for maintaining a sustainable and eco-friendly environment.

- Q:What are the different fabrication methods used for aluminum sheets?

- Aluminum sheets undergo various fabrication methods, each presenting its own advantages and applications. Rolling, extrusion, casting, and stamping are among the most commonly employed techniques. Rolling, the most prevalent method, entails passing the aluminum through a series of rollers to reduce thickness and form a flat sheet. This approach allows for precise control over sheet thickness and shape, rendering it suitable for an array of applications, from packaging to building materials. Another well-received method is extrusion, where heated aluminum is pushed through a die to create a specific shape or profile. This technique is commonly employed to manufacture intricate shapes like tubes, rods, and channels. Extruded aluminum sheets exhibit high strength and durability, making them appropriate for structural applications in construction and automotive industries. Casting involves pouring molten aluminum into a mold, allowing it to solidify. This method is frequently used for producing intricate shapes that are challenging to achieve through other means. Cast aluminum sheets can boast unique textures and designs, making them popular for decorative purposes. Stamping utilizes a press to shape the aluminum sheet by exerting pressure and forming it into the desired shape. This technique is commonly utilized for creating precise, small parts such as brackets, connectors, and electrical components. Stamped aluminum sheets offer exceptional dimensional accuracy and can be produced in large quantities at a relatively low cost. Additionally, other fabrication techniques such as welding, bending, and laser cutting can be employed to further process aluminum sheets and craft custom shapes and designs. In conclusion, the choice of fabrication method for aluminum sheets relies on the desired application, required properties, and complexity of the desired shape. Each method possesses unique advantages and capabilities, enabling a broad range of possibilities in aluminum sheet fabrication.

- Q:What is the corrosion resistance of aluminum sheets?

- Aluminum sheets have excellent corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface when exposed to oxygen, which acts as a barrier against corrosion. This oxide layer is very stable and prevents further oxidation of the metal, making aluminum highly resistant to corrosion in most environments. Additionally, aluminum sheets can be further enhanced with surface treatments or coatings to increase their corrosion resistance even more. This makes aluminum sheets a popular choice for various applications where corrosion resistance is crucial, such as in the construction industry, automotive manufacturing, and marine applications.

- Q:What is the reflectivity of 101 aluminum sheets?

- The reflectivity of 101 aluminum sheets can vary depending on a few factors such as the surface finish, thickness, and any additional coatings or treatments applied to the sheets. Generally, aluminum has a high reflectivity, especially in the visible light spectrum. It can reflect around 80% to 90% of visible light, making it a popular material for reflective surfaces, mirrors, and various lighting applications. However, it is essential to note that the exact reflectivity of 101 aluminum sheets may differ based on specific manufacturing processes or variations in the material properties.

- Q:What are the colors of iron sheet and aluminum sheet?

- both of them are silver white.

- Q:Can the aluminum sheets be used for manufacturing electrical connectors?

- Indeed, electrical connectors can be manufactured using aluminum sheets. The lightweight and exceptional conductivity of aluminum render it ideal for the efficient transmission of electricity. Its outstanding conductivity and ability to resist corrosion make it a frequently employed material in diverse electrical applications, particularly connectors. Furthermore, the malleability and ease with which aluminum can be molded into diverse connector designs make it an adaptable material for the production of electrical connectors.

- Q:If one were to hit someone with a baseball bat, would it cause more pain to use a wooden bat or an aluminum one? Just wondering.

- I've been chased with an aluminum bat, but haven't ever been hit with either. I would say that the wooden bat would hurt more, because that's solid wood. An aluminum bat is hollow. But then yet, I've red articles where aluminum bats perform better for some kind of scientific reason that I didn't quite understand. So if an aluminum bat performs better on a baseball, it would be safe to assume that perhaps it would hurt more to be hit with an aluminum one. But either way, it's safe to say... I'd rather not be hit with either!

- Q:How does the thickness tolerance of aluminum sheet affect its usability?

- The thickness tolerance of aluminum sheet plays a significant role in its usability. A narrow thickness tolerance ensures uniformity and precision in the sheet's dimensions, allowing for consistent performance and ease of fabrication. It enables seamless integration into various applications, including construction, automotive, aerospace, and manufacturing industries. On the other hand, a wider thickness tolerance can limit its usability as it may result in irregularities, difficulty in fitting, and potential performance issues. Therefore, a tight thickness tolerance is crucial for ensuring optimal functionality and versatility of aluminum sheets.

- Q:I have to find the type of bond that Aluminum (foil) would have. I know that it has some kind of bond to it because that's the kind of question that I got wrong on my last quiz.

- Yes it will be a covalent bond. The simplest compound will be CH4 where each of the electron from the four H will be shared with one each from C to provide 4 covalent bonds.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium FIve Bars for Skid Resistance Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords