Halogen Free Flame Retardant Thermoplastic Elastomer Compound for Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

plastic granules:

Halogen Free Flame Retardant TPE Compound used for power cable

plastic granules: 1, Type and application: Used for Japanese standard power cable and electrical equipment cable

2, Introduction Environmental friendly halogen-free TPE cable compound, based on styrene elastomer, is made into granular by mixing, plasticization and granulation with special modifier, and other special additives. It has goodresilience, scratch-resistant and flexibility. The products meet various special requirements, such as different hardness, UV stable, fog surface and etc. This material, with exquisite and smooth appearance, has excellent performance of anti yellowing, weather resistant temperature resistance, without halogens, heavy metals, meeting the RoHS, REACH, and other environmental standards. 3, Processing: The compound can be processed with conventional extruders, and the screw with a minimum 25:1 L/D and a compression ratio of 2.5 is recommended. The following temperature(°C) profile of extruder is recommended: Note:Compound should be dried at 80-90°C before use, which has been stored more than one month. 4, Storage and transport Packaging:20kg/bag,Aluminum foil and PE film inside bag, and PP composite outside bag. Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated. 5, Properties: |

Item | Unit | Typical | |||||||

E3685A | E3688B | E3690A | E3692A | E3692B | E3689A | ED3685 | EA3685 | ||

Density | g/cm3 | 1.11±0.03 | 1.09±0.03 | 1.14±0.03 | 1.08±0.03 | 1.10±0.03 | 1.10±0.03 | 1.10±0.03 | 1.10±0.03 |

Hardness | Shore A | 85±3 | 88±3 | 90±3 | 92±3 | 92±3 | 89±3 | 85±3 | 85±3 |

Melt Index 230℃×5kg | g/10min | 1.2 | 2.6 | 1.1 | 1.0 | 0.8 | 1.5 | 1.3 | 2.0 |

Tensile Strength | MPa | 15 | 12 | 13 | 16 | 13 | 14 | 12 | 11 |

Elongation at Break | % | 280 | 260 | 250 | 270 | 260 | 260 | 240 | 300 |

Thermal aging | ℃*h | 136℃*168h | |||||||

TS retention | ≥75% | 97 | 99 | 101 | 102 | 101 | 97 | 99 | 109 |

EB retention | ≥75% | 83 | 81 | 79 | 82 | 80 | 81 | 82 | 78 |

Hot deformation | ℃*h | 150℃*1h | |||||||

Variation | ≤50% | 15 | 13 | 12 | 8 | 6 | 9 | 7 | 38 |

pH of gases evolued | -- | 6.3 | 6.5 | 5.3 | 5.6 | 6.2 | 5.6 | 5.5 | 5.3 |

Conductivity of Gases evolved | ≤μm/mm | 1.4 | 1.3 | 1.5 | 1.2 | 1.1 | 1.2 | 1.0 | 1.3 |

Oxygen index | O2 % | 26 | 27 | 27 | 27 | 26 | 27 | 27 | 27 |

Impact Brittleness Temperature | -60 ℃ | Pass | Pass | Pass | Pass | Pass | Pass | Pass | Pass |

Volume Resistivity, at 20℃ | Ω﹒m | 3.7×1014 | 3.5×1014 | 4.3×1014 | 3.5×1014 | 3.2×1014 | 4.1×1014 | 4.3×1014 | 5.4×1014 |

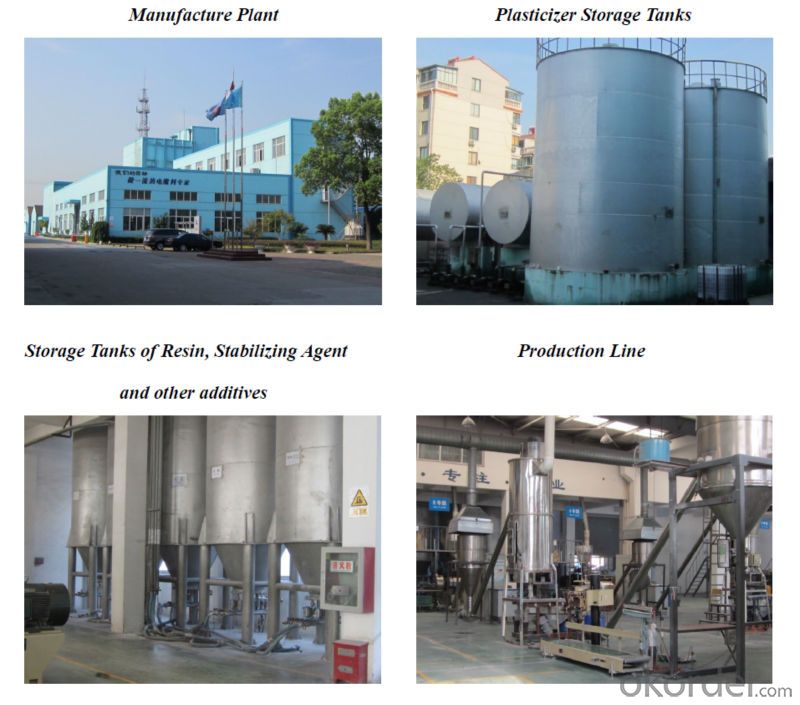

6. Company

- Q: Low pressure plastic raw materials in the process of blowing the two sides of the fold, how to deal with?

- Blow up ratio of transverse expansion ratio of the film, is actually on the orientation of the transverse tensile film, tension will have a certain degree of plastic molecules, the blowing ratio is increased, thereby improve the lateral strength of thin films.

- Q: What are the concepts, classifications and distinctions of modified plastics and plastic materials?

- Modified plastics should, in principle, be made from the plastic raw materials produced by petrochemical plants. By adding plastic additives, they can enhance their hardness, fire resistance, high temperature or low temperature, weather resistance and ultraviolet resistance. Therefore, modified plastics are processed from plastic raw materials, which is the relationship between source and flow.

- Q: Raw materials for making plastic bags

- The common food plastic bags are made of polythene film. The film is non-toxic and can be used to hold food. There is also a film made of PVC, PVC itself is non-toxic, but according to the use of film additives are often harmful to human substances, has a certain toxicity. Therefore, this kind of film and plastic bag made of this film should not be used for containing food.

- Q: What are the APP of plastic raw materials?

- Thermosetting plastics (phenolics, epoxy resins, unsaturated polyesters, polyurethanes, silicones, amino resins, etc.);

- Q: What are the raw materials for plastic products? Resin or oil?

- Molded plastic: a resin mixture for molding. Such as thermosetting plastics.Laminated fabric: a fabric impregnated with a resin that can be laminated and pressed together to form an integral material.Injection, extrusion and blow molding plastics: - refers to a mixture of resins that can melt and flow at the cylinder temperature and rapidly harden in the mold. Such as general thermoplastic plastics.Casting liquid: a liquid resin mixture that can be poured into a mold and hardened into a definite shape in case of no pressure or little pressure. Such as MC nylon.Reaction injection mold plastic: generally refers to liquid raw material, pressurized injection mold cavity, so that the reaction of curing, finished products. Such as polyurethane.

- Q: What are the raw materials of plastics made of?

- Synthetic resin refers to coal, petroleum, natural gas, calcium carbide and some agricultural products as the main raw material, the low molecular weight compounds prepared firstly has certain synthetic conditions (monomer), and then through chemical and physical methods for the synthesis of high molecular compound. The characteristics of this kind of compounds similar to natural resin (such as rosin, shellac, amber, etc.), but the performance and more superior than the natural resin.

- Q: What kinds of plastic properties can be divided into thermal properties?

- Classification of plastics (100 million nylon)There are many kinds of plastics. There are many kinds of classification methods. They are usually divided into two categories: thermoplastic and thermosetting plastics according to the change of their properties after heating.

- Q: What are the raw materials for environmental friendly portable plastic bags?

- [environmental protection portable plastic bags] generally speaking, there is no fully environmentally-friendly plastic bags, only some plastic bags to add some ingredients, it is easy to degrade some. Biodegradable plastic. The main material is low pressure polyethylene plastic, in the production of plastic packaging products to add a certain amount of additives, such as starch, modified starch or other cellulose, photosensitizer, biodegradable agent.

- Q: What are the heavy bags in the plastic material?

- Plastic raw materials in the heavy bag refers to high pressure polyethylene (LDPE) is a kind of special, for the production of plastic packaging bags, the plastic bags bearing force and pulling force are high, and have a high degree of transparency, plastic raw materials sales is often called the heavy bag material, melting point to: 0.3

- Q: What does MFI mean in PC material?

- The measurement of MI is usually based on the standard method of ASTM D1238. It is the principle of the plastic or resin into the metal sleeve of a fixed inner diameter, and heating the plastic or resin after melting, and then give some load on the piston, the piston on the weight of the molten plastic has been squeezed out from a small hole in the charge, and calculate the weight and squeezed out of plastic. This measuring method, because of the same material, the sleeve barrel inner diameter, load, and temperature are fixed, so in addition to test MI, can also be used for the determination of density, viscosity, and melt shear rate, shear stress... etc.

Send your message to us

Halogen Free Flame Retardant Thermoplastic Elastomer Compound for Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords