Halogen Free Non Flame Retardant Thermolastic Elastomer compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

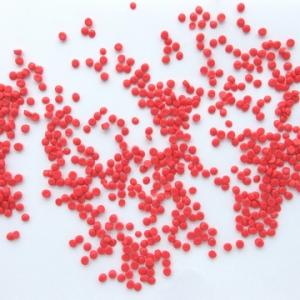

plastic granules:

Halogen free non-flame retardant TPE cable compound

plastic granules: 1, Type and application: Used for non-flame retardant data cable

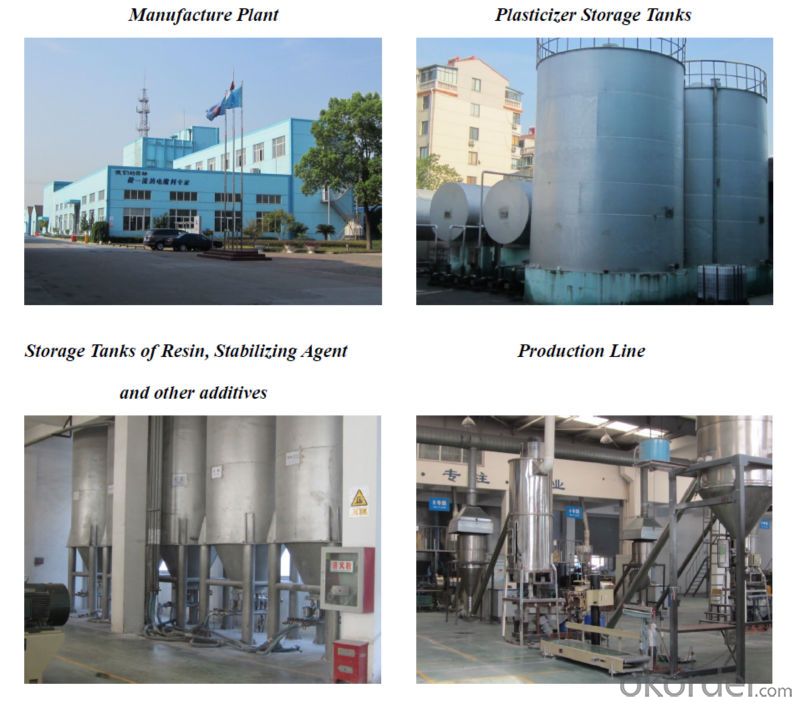

2, Introduction Environmental friendly halogen-free TPE cable compound, based on styrene elastomer, is made into granular by mixing, plasticization and granulation with special modifier, and other special additives. It has goodresilience, scratch-resistant and flexibility. The products meet various special requirements, such as different hardness, UV stable, fog surface and etc. This material, with exquisite and smooth appearance, has excellent performance of anti yellowing, weather resistant temperature resistance, without halogens, heavy metals, meeting the RoHS, REACH, and other environmental standards. 3, Processing: The compound can be processed with conventional extruders, and the screw with a minimum 25:1 L/D and a compression ratio of 2.5 is recommended. The following temperature(°C) profile of extruder is recommended: Note:Compound should be dried at 80-90°C before use, which has been stored more than two months. 4, Storage and transport Packaging:20kg/bag,PE film inside bag, and PP composite outside bag. Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated. 5, Properties: 6,Company Pictures

|

- Q:Characteristics of rigid polyurethane foam made of polyurethane raw material

- Polyurethane rigid foam is prepared by hard foam polyether polyol (polyurethane rigid foam combination polyether, also known as white material) and polymerized MDI (also known as black material). Mainly used in the preparation of rigid polyurethane foam, widely used in refrigerators, cold storage, spraying, solar energy, thermal pipelines, construction and other fields. According to the use of the field, divided into rigid foam polyether polyol, polyether, wood cyclopentane system hard foam polyether polyol, polyether, flame retardant polyether water. The wood is mainly used for imitation wood product polyether, polyether and water is mainly used for all water pipe foam, flame retardant polyether products for preparation of flame retardant high requirements.

- Q:Low pressure plastic raw materials in the process of blowing the two sides of the fold, how to deal with?

- The blowing ratio is one of the control points of blown film production and! Refers to the ratio between the bubble diameter and the diameter of not blowing blowing after.

- Q:What are the raw materials of plastics made of?

- The plastic is made of natural or synthetic resin as the main ingredient, adding various additives, in certain conditions such as temperature and pressure can be made into a certain shape, keep shape materials at room temperature.

- Q:What kinds of plastic properties can be divided into thermal properties?

- Classification of plastics (100 million nylon)There are many kinds of plastics. There are many kinds of classification methods. They are usually divided into two categories: thermoplastic and thermosetting plastics according to the change of their properties after heating.

- Q:What material is the disc made of, metal or plastic?

- In general, the substrate is colorless and transparent polycarbonate board, in the entire disc, it is not only the carrier of the groove, but also the physical shell of the whole cd.

- Q:How to identify the proportion of nozzle material in plastic?

- The melt index is detected by a melt flow rate analyzer. If the nozzle is added, the melt index will generally increase

- Q:How is plastic material made out?

- Some plastics are made up of synthetic resins, with or without additives such as plexiglass and polystyrene. The so-called plastic, in fact, it is a kind of synthetic resin, the shape of the natural resin with pine resin similar, but also because of the chemical strength of the synthesis, and is called plastic.

- Q:What are the materials for making plastic buckets? How many are there?

- Domestic plastic bucket source material basically two kinds: blow molding with PE injection: PP

- Q:Chemical, plastic raw materials, plastic raw materials how sub grade?

- Plastic bucket is usually added to the resin, in the production of lubricants, plasticizers, dispersant, pigment, polyethylene wax, and these materials good variety, price range, and some high melting point, good whiteness, production out of the finished product is good texture, high brightness, good conscience manufacturers add some heat thermoplastic elastomer, feel very well; and a point of the raw materials, the relative performance is low, the production of plastic barrels must be of poor quality.

- Q:What is the raw material for producing corn starch plastic film?

- It is corn starch raw materials of corn plant starch is a natural polysaccharide polymer, the molecular weight of up to 3 million Dalton, is a common concern at home and abroad can be used as the ideal material for the direct application of the polymer materials. Plant starch is divided into grain starch (corn starch, sorghum starch, wheat starch, rice starch) and potato starch (tapioca starch, potato starch, konjac starch).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Halogen Free Non Flame Retardant Thermolastic Elastomer compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords