Geomembrana De Pvc Precio

Geomembrana De Pvc Precio Related Searches

Geomembrana Pvc Precio Geomembrana De Pvc Precio De Geomembrana Precio De La Geomembrana Geomembrana Pvc Geomembrana De 1 Mm Precio Tanques De Geomembrana Precios Precio De Geomembrana Por M2 Rollo De Geomembrana Precio Geomembrane Price Cuanto Cuesta La Geomembrana Pvc Geomembrane Harga Geomembrane Precios De Geomembrana En Mexico Geomembrana Precio Mexico Venta De Geomembrana Geomembrana Precio M2 China Pvc Geomembrane Harga Geomembrane Per M2 Geomembrana 1.5 Mm Precio Estanques De Geomembrana Precios Geomembrane Cost Pvc Geomembrane Specifications Geomembrana De Polietileno Harga Geomembrane Per Roll Venta De Geomembrana En Puebla Geomembrane Liner Price Geomembrana Hdpe 1 Mm Precio Pvc Geomembrane Liner Pvc Geomembrane InstituteGeomembrana De Pvc Precio Supplier & Manufacturer from China

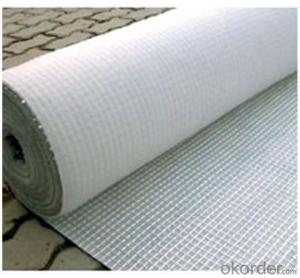

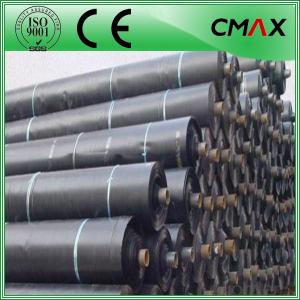

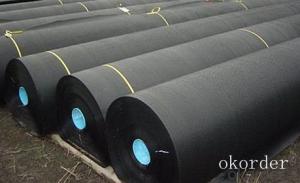

Geomembrana De Pvc Precio is a high-quality PVC geomembrane product that is widely used in various applications such as landfill liners, water reservoirs, and canal linings. This product is known for its excellent chemical resistance, durability, and flexibility, making it a popular choice in the construction industry.The PVC geomembrane, Geomembrana De Pvc Precio, is utilized in a variety of scenarios where waterproofing and containment are required. It is commonly employed in environmental protection projects, such as waste containment facilities and water treatment plants, as well as in the construction of ponds, reservoirs, and irrigation channels. Its versatility and effectiveness in preventing leakage and contamination make it an essential component in these projects.

Okorder.com is a leading wholesale supplier of Geomembrana De Pvc Precio, offering a vast inventory to meet the demands of various projects. With a commitment to quality and customer satisfaction, Okorder.com ensures that the PVC geomembrane products are delivered promptly and in excellent condition. This makes them a reliable source for those seeking to purchase Geomembrana De Pvc Precio for their specific applications.

Hot Products