Venta Geomembrana - Dimple Composite Geomembrane Quality Guaranteed, Low Price Promised

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

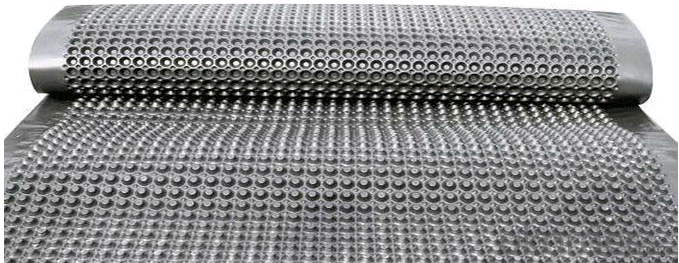

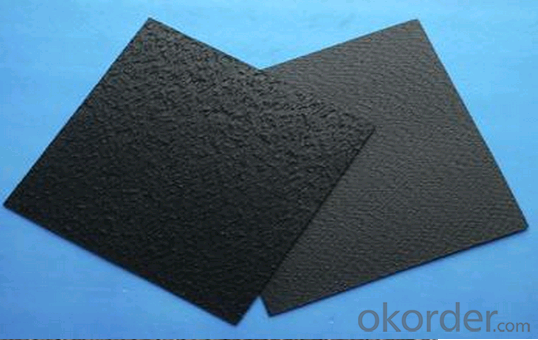

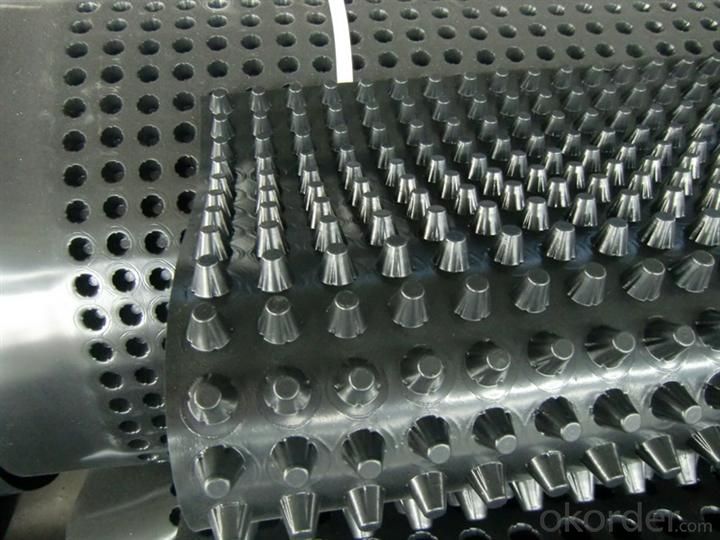

EltMembrane-CDG series of geomembrane is manufactured from High Density Polyethylene resins. Produced by extruding plastic sheet into dimple shape.These dimples,in spatial structure with certain height. Can resist long-term high pressure without deformation. On the top of the dimples, there is filtration geotextile to make sure the drainage channel ruing well without any block for any articles. For example,filling particles or concrete.

Advantages

1. strong viscosity, cold pressing sensitive

2. color white/black

3. accurate size cutting

4. custom size offered without any surcharge

Application

1, Municipal projects

2,Landfill treatment projects

3,Waste water treatment

4,Mineral waterproofing

| Composite Dimple geomembrane | |||||||

| NO. | Item Name | Technical requirements | |||||

| H10-1.0 | H20-1.0 | H10-1.5 | H20-1.5 | H10-2.0 | H20-2.0 | ||

| 1 | Tensile strength N/<5cm> ≥ | 400 | 400 | 500 | 500 | 700 | 700 |

| 2 | Elongation at break % ≥ | 200 | 200 | 300 | 300 | 400 | 400 |

| 3 | Dimensional strength Mpa ≥ | 400 | 320 | 450 | 370 | 500 | 420 |

| 4 | Dimensional stability % | ±2 | |||||

| 5 | Low tempreture impact brittle property | -35℃ crack-free bending | |||||

| 6 | Longitudinal flow capacity cm3/s( hydraulic pressure 5Kpa) | 5.6 | 8.6 | 5.6 | 8.6 | 5.6 | 8.6 |

| 7 | Longitudinal flow capacity cm3/s( hydraulic pressure 350Kpa) | 15.2 | 18.2 | 15.2 | 18.2 | 15.2 | 18.2 |

FAQ

Q: Can you accept sample order?

A: Yes, we are willing to send small samples for free, while the shipping fee should be afforded by yourself.

Q: What is your delivery time?

A: 1 days for samples, two weeks for mass production.

Q: What is your payment terms?

A: T/T , L/C, Western Union, Money Gram. 30% advance before producing, 70% payment before deliverying.

Q: How can I get my order?How can I know you sent the goods.

A: We will send you the goods by UPS, DHL, Fedex, Oversea Shipment or other forwarder,

all with tracking number or B/L.

Q:How about your quality?

A: Try a small order, you will have your own judgment!

- Q: Are geomembranes resistant to electrical conductivity?

- Yes, geomembranes are generally resistant to electrical conductivity. They are designed to be electrically insulating materials, which means they have a low ability to conduct electricity. This property makes them suitable for various applications where electrical isolation is required, such as in containment systems for hazardous waste or in lining ponds and reservoirs. However, it is important to note that the electrical resistance of a geomembrane can vary depending on its composition and specific properties.

- Q: What is the size of 156 inch computer film?

- They are a little bit small like the Samsung Galaxy, LG G2 phone. There is certain radian at the edge of the screen. Plane film can't completely match arc and film can just cover the plane part of the screen, so it looks like that film is obviously smaller than the screen.

- Q: How do geomembranes prevent water leakage in swimming pools?

- Geomembranes prevent water leakage in swimming pools by creating a waterproof barrier that is impermeable to water. These specially designed membranes are installed as a lining on the walls and floor of the pool, effectively sealing it from any potential leaks.

- Q: What is national standard of geomembrane?

- Geomembrane national standards have not requirements for construction loss. Do you want to ask lapping? Normal lapping is 15-20CM.

- Q: What are the technical parameters of unidirectional geogrid?

- The technical parameters of unidirectional geogrid can be divided into two categories. Unidirectional polypropylene geogrid is usually used in the project of reinforcement or ground treatment. Specification: TGDG80 The polyethylene product is usually used in the construction of reinforced soil retaining wall or abrupt slope. Specification: TGDG80 (HDPE). Check the national standard if there is something not understood. GB\T17689-2008

- Q: Can geomembranes be used in water containment systems?

- Yes, geomembranes can be used in water containment systems. They are impermeable synthetic liners that are highly effective in preventing seepage and leakage of water in various applications such as reservoirs, ponds, lakes, landfills, and wastewater treatment plants. Geomembranes provide a reliable and durable barrier to contain water, ensuring its safe storage and preventing contamination or loss.

- Q: How do geomembranes help in groundwater recharge projects?

- Geomembranes help in groundwater recharge projects by acting as a barrier to prevent the loss of water through seepage and infiltration. They are used to line the recharge basins or ponds, ensuring that the water is effectively contained and slowly percolates into the ground, replenishing the groundwater reserves. This not only helps to conserve water but also prevents contamination and ensures the efficient recharge of aquifers.

- Q: Is it useful to stick film for iPhone?

- Yes, it is. 1. The gardness of iPhone glass is larger than fingernails and metals like keys, so these things scratch it. 2. Many components in dust and sand wind, such as quartz, is harder than the glass. For example, if some grains of sand containing quartz in your hand, they will cause permanent scratches to the iPhone glass. 3. In terms of the service time, the mobile phone is a durable product, but after 2 or 3 years, you will buy a new one. 4. Therefore, if you use it carefully and do not mind scratches, you need not to stick film, otherwise you had better stick film.

- Q: What are the considerations for geomembrane selection in hazardous waste containment?

- When selecting a geomembrane for hazardous waste containment, several considerations must be taken into account. Firstly, the geomembrane material must possess high chemical resistance to ensure it can withstand potential chemical interactions with the hazardous waste. Additionally, the geomembrane should have a low permeability to prevent any leakage or migration of the hazardous substances. It is crucial to assess the mechanical properties of the geomembrane, such as tear resistance and puncture strength, to ensure it can withstand the stresses and strains that may occur during installation and throughout its service life. The geomembrane's ability to withstand ultraviolet (UV) radiation and environmental factors is also important, as it should retain its integrity over time. Lastly, considerations such as cost-effectiveness, availability, and compliance with regulatory standards should be evaluated when selecting a geomembrane for hazardous waste containment.

- Q: How do geomembranes contribute to the prevention of soil contamination from agricultural chemicals?

- Geomembranes contribute to the prevention of soil contamination from agricultural chemicals by acting as a barrier between the chemicals and the soil. They are impermeable liners that prevent the chemicals from leaching into the soil, thus reducing the risk of contamination. By effectively containing the chemicals, geomembranes help protect the soil quality and preserve its fertility, ensuring sustainable agricultural practices.

Send your message to us

Venta Geomembrana - Dimple Composite Geomembrane Quality Guaranteed, Low Price Promised

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords