Geotextiles UK - Polyethylene HDPE Geotextile Membrane Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

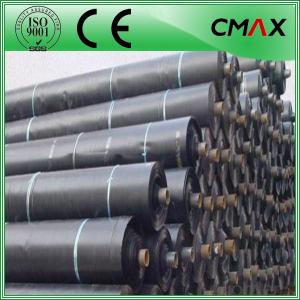

HDPE Geomembrane

Thickness: 1.0mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

LDPE Geomembrane

Thickness: 0.1mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

LLDPE Geomembrane

Thickness: 0.5mm to 3.0mm

Roll Size: 4m-9m in width

roll length as design or client’s request

Type:

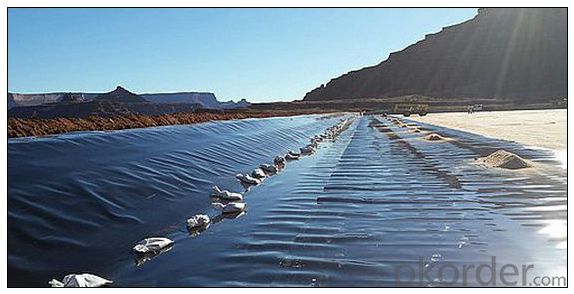

Waterproof Membrane

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

ISO

Sample:

Available

Color:

customized

width:

4m-9m

thickness:

1mm-3mm

length:

customized

material:

geotextile+HDPE membrane/geote

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: Can geotextiles be used for slope stabilization?

- Yes, geotextiles can be used for slope stabilization. Geotextiles are commonly used in civil engineering projects to reinforce soil and prevent erosion. By placing geotextiles on slopes, they can provide stability by distributing the forces acting on the slope and improving soil cohesion. Additionally, geotextiles can help with drainage, filtration, and vegetation growth, further enhancing slope stability.

- Q: Geotextile how to set quota

- Geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. With excellent filtration, isolation, reinforcement protection, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Borrow the municipal or highway quota corresponding sub-head, according to the actual adjustment of the price, or directly hit b: 001 input price (the price is included in the artificial materials machinery) geotextile, also known as geotextile, it is by the synthetic fiber through the needle Thorn or woven from the permeability of geosynthetics, the physical structure of multi-layer film. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. The set of quotas is a technical term in the project budget. In the project budget, the budget is the basic principle: to calculate the amount of engineering, and then multiplied by the price, and ultimately draw the total cost of the project, the total cost

- Q: How do geotextiles help in preventing soil contamination?

- Geotextiles help prevent soil contamination by acting as a barrier between the soil and potentially harmful substances. They can prevent the infiltration of pollutants such as chemicals, oils, or waste materials into the soil, thereby protecting the soil quality and preventing contamination. Additionally, geotextiles can also help in stabilizing soil erosion, reducing sediment runoff, and enhancing filtration, thus further preventing soil contamination.

- Q: What are the factors to consider when maintaining geotextiles?

- When maintaining geotextiles, there are several factors to consider. Firstly, it is important to regularly inspect the geotextiles for any signs of damage or wear. This includes checking for tears, holes, or fraying, as well as monitoring the overall condition of the material. Secondly, it is crucial to properly clean the geotextiles to prevent the buildup of dirt, debris, or organic matter that can compromise their effectiveness. This may involve using appropriate cleaning methods such as gentle washing or vacuuming. Additionally, considering the environmental and weather conditions in the specific location where the geotextiles are installed is essential. Extreme temperatures, UV exposure, and moisture levels can impact the durability and longevity of the material, so appropriate protective measures should be taken to mitigate these factors. Lastly, regular maintenance should include reassessing the performance of the geotextiles and their compatibility with the intended application. This may involve consulting with experts or conducting periodic testing to ensure that the geotextiles continue to meet the required standards and objectives. Overall, diligent inspection, cleaning, protection, and evaluation are key factors to consider when maintaining geotextiles.

- Q: what do you mean nonwoven geotextiles ???

- please refer the folowing url to know all the details about non woven geo textiles

- Q: What are the key factors affecting the creep behavior of geotextiles?

- The key factors affecting the creep behavior of geotextiles include the material properties of the geotextile itself, such as its tensile strength, elongation capacity, and viscoelastic behavior. The load applied to the geotextile, including the magnitude and duration, also plays a significant role in its creep behavior. Environmental conditions, such as temperature, moisture, and UV exposure, can further influence the creep performance of geotextiles. Additionally, the installation and stress transfer mechanisms between the geotextile and adjacent soils or structures can affect its creep behavior.

- Q: What are the different geotextile installation techniques in filtration?

- There are several different geotextile installation techniques used in filtration, including direct placement, trench installation, and slope installation. Direct placement involves spreading the geotextile directly on the ground and securing it with stakes or sandbags. Trench installation involves placing the geotextile in a trench and backfilling it with soil. Slope installation is used on steep slopes and involves anchoring the geotextile with staples or other fasteners. These techniques help ensure proper filtration and erosion control in various applications.

- Q: What are the different factors to consider when selecting a geotextile?

- When selecting a geotextile, there are several factors to consider. Firstly, the intended application of the geotextile should be taken into account. Different geotextiles are designed for specific purposes such as erosion control, filtration, separation, reinforcement, or drainage. Secondly, the physical properties of the geotextile, including its tensile strength, puncture resistance, permeability, and durability, should be evaluated to ensure they meet the requirements of the project. Additionally, the environmental factors, such as the soil conditions, water chemistry, and climate, should be considered to ensure the geotextile can withstand the site-specific conditions. Lastly, the cost-effectiveness and availability of the geotextile should also be taken into consideration to ensure it aligns with the project budget and timeline.

- Q: Geotextile drainage network and geotextile how to heat stick

- Geotextile and geotextile crimp part of the use of sewing or hot air welding. Hot air welding is the connection method of filament geotextile, that is, with the hot air gun on the connection of two pieces of cloth instantaneous high temperature heating, so that part of the molten state, and immediately use a certain external force to make it firmly together. In the case of wet (rain and snow) weather can not be hot adhesive connection, geotextile should take another method of a suture connection method, that is, with a dedicated sewing machine for two-wire suture connection, and the use of anti-chemical UV suture.

- Q: What are the considerations for geotextile selection in riverbank stabilization?

- There are several important considerations for geotextile selection in riverbank stabilization. Firstly, the geotextile must have sufficient strength and durability to withstand the hydraulic and environmental conditions of the specific riverbank. Additionally, it should have good filtration properties to prevent soil erosion and promote water drainage. The geotextile's permeability and porosity are also crucial factors, as they determine the rate of water flow and allow for proper drainage. Lastly, the geotextile should be compatible with other materials used in the stabilization process and be able to withstand any chemical exposure or biological degradation that may occur in the riverbank environment.

Send your message to us

Geotextiles UK - Polyethylene HDPE Geotextile Membrane Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords