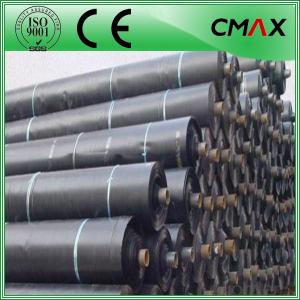

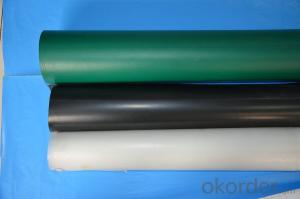

Terpal PE/EVA Geomembrane Pond Liners Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PE Smooth Geomembranes:

PE smooth geomembranes are designed for waste containment applications that require greater flexibility and elongation performance. Our superior tensile properties make PE smooth geomembrane liners the perfect solution for applications in which flexibility and elongation are most important, such as:

Solid Waste Landfills,

Hazardous Waste Landfills and C & D Landfills

Mining

Industrial and municipal water and wastewater treatmen

Number | Test property | Value |

1 | Thickness/mm | 0.2-3 |

2 | Width /m | 2.5-9m |

3 | Tensile Strength(TD/MD)Mpa | ≥16 |

4 | Elongation at Break(TD/MD)% | ≥700 |

5 | Strength at Tear(Right-angle Tear)N/mm | ≥60 |

6 | Permeability Coefficient of Vapour | <1.0x10 -13 |

7 | The range of Temperature | -70 degrees to 70 degrees. |

FQA:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: How do geomembranes perform in high-pressure gas containment applications?

- Geomembranes are highly effective in high-pressure gas containment applications. They are designed to be impermeable, providing an excellent barrier against gas leakage. Their durability and strength enable them to withstand the high pressures exerted by gases without rupturing or deforming. Additionally, geomembranes have low gas permeability, preventing the escape of gases and ensuring containment integrity. Overall, geomembranes perform exceptionally well in high-pressure gas containment applications, offering reliable and long-lasting protection.

- Q: What are the standards of PE seepage-proof geomembranes?

- Urban construction standards, American Standards, home 1 and 2 standards

- Q: What's the function of the base membrane of wall cloth?

- Base films are basically universal for they have the same functions.

- Q: What exactly is the geomembrane? What are the applications?

- At the same time, alkali and salt corrosion, long service life; and non-woven fabric is also a kind of high-molecule short fiber chemical material. Geomembrane construction site its main mechanism is to use imperviousness of plastic film to cut off earth dam leakage passage, not only increases the tensile strength and anti-puncture ability of plastic film. They have good corrosion resistance to bacteria and chemical action, which is conducive to the stability of composite geomembrane and protective layer, with high tensile strength and extensibility, bearing the hydraulic?pressure and adapting to dam deformation with its large tensile strength and ductility, increasing the friction coefficient of the contact surface. And due to the roughness of the non-woven surface, geomembrane construction site its main mechanism is to use imperviousness of plastic film to cut off earth dam leakage passage; and non-woven fabric is also a kind of high-molecule short fiber chemical material, bearing the hydraulic?pressure and adapting to dam deformation with its large tensile strength and ductility, through needle punching or hot sticking forming, it is combined with plastic film, used in the dark place, not afraid of acid

- Q: How thick is the film for furniture? how to differentiate the home film from other films.

- Probably 200 microns thick Ha. Nano-ceramic furniture protective film, referred to as furniture foil, translucent, repairing minor scratches, fire high temperature (225 degrees), radiation (stone furniture), easy to clean, long life, in line with modern green healthy fashion requirements and so on. Applies to: Homes, offices, restaurants, hotels, large and small restaurants, furniture and other ancillary companies. Nano-ceramic film of high transparency furniture, furniture can fully reflect the desktop pattern and color, permanent protection as new. Nano-ceramic furniture foil insulation and ultra-high wear-resistant, so that when you use the desktop will not worry about the furniture scratches and scorch the paint. Nano-ceramic film good decontamination furniture, non-stick oil, smooth surface, do not move, easy to clean. Nano ceramic furniture film does not affect the character of furniture and furniture performance of the premise, to provide protection to the furniture. Nano furniture foil, is the use of high-grade super-transparent polymer with a number of precious metals (such as silver) joint action by sputtering indium oxide, the outer layer of an acrylic-based transparent, very tough. This produced a film with high transparency and heat insulation effect, the surface is very wearable. Nano-ceramic film of high transparency furniture, furniture can fully reflect the desktop pattern and color, permanent protection as new. Nano-ceramic furniture foil insulation and ultra-high wear-resistant, so that when you use the desktop will not worry about the furniture scratches and scorch the paint. Nano-ceramic film good decontamination furniture, non-stick oil, smooth surface, do not move, easy to clean. Nano furniture foil under furniture without affecting the character and performance of the premise of furniture, furniture protection, is the best protector of furniture.

- Q: Can geomembranes be used for decorative purposes?

- No, geomembranes are primarily used for functional purposes such as containment and lining systems in various industries and environmental applications. They are not designed or commonly used for decorative purposes.

- Q: How to judge the quality of geomembrane?

- If there is no professional testing equipment, the following ways of identification can be used, can resist most of the plant roots. 3: 1, has excellent anti-puncture ability. Good geomembrane elongation 4, decomposition resistance capacity, and then draw back with efforts. Bad one has no lustre, glossy, cut 5 cm wide strips on geomembrane, can be barely used. visual inspection. Good geomembrane is black and bright, bad geomembrane is easy to crack. Repeatedly rub, tensile testing, the materials service life is up to 30-70 years, anti ultraviolet. 2. Good geomembrane will not crack if repeatedly rubbed, good geomembrane has excellent anti-aging property. 5 times will not break

- Q: How do geomembranes contribute to the prevention of soil salinization?

- Geomembranes can help prevent soil salinization by acting as a barrier, preventing salty water or brine from infiltrating the soil. They are impermeable to water and salts, effectively minimizing the contact between saline solutions and the underlying soil. This helps maintain the soil's natural balance and prevents the accumulation of salts, which is a major cause of soil salinization.

- Q: What are the sticking methods of computer film?

- First step of film sticking: aim the film marked ① at the screen and pull the ① layer of release liner label, slowly tear a part of this layer, pay attention not to touch the adsorbed layer (middle layer) of the protective?film with fingers. Second step of film sticking: aim the adsorbed layer at the screen corner, make sure that the position is aligned, smooth the film carefully while tearing off the backing layer ① release liner. Because present protective film has electrostatic automatic adsorption function, generally it does not need be ironed too much. The action should be slow when sticking the film, and it is recommended to start sticking along the long side of the screen, from point to line, from line to surface successively

- Q: Can geomembranes be used in groundwater extraction wells?

- Yes, geomembranes can be used in groundwater extraction wells. They can be used as a lining material to prevent contamination of the extracted groundwater and to ensure its quality. Geomembranes act as a barrier between the well structure and the surrounding soil, preventing the migration of pollutants or unwanted substances into the well. This helps in maintaining the integrity of the groundwater supply and protecting it from external influences.

1. Manufacturer Overview

| Location | Taian City,Shandong Province,China |

| Year Established | 2003 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, North America, Eastern Europe, South Asia, Western Europe |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port;Tianjing Port;Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Geotechnical Material (Geogrid,Fiberglass/Polyester Geogrid;Geocell;Geonet and Geomat;Plastic Safety Fence);Plastics products;Rubber products;Geotextile;Carpet;Compound geomembrane |

| Product Price Range | Average |

Send your message to us

Terpal PE/EVA Geomembrane Pond Liners Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords