Geomembrana Para Techos LLDPE 1.2mm para Ingeniería Arquitectónica

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrane LLDPE for Architectural Engineering

Description Of Geomembrane LLDPE for Architectural Engineering

Geomembrane, water-proof plate, is made from polymer materials like polyethylene, through blow molding.

Main Features of Geomembrane LLDPE for Architectural Engineering

molecular structure, Polyethylene (PE) geomembrane is divided into low-density polyethylene (LDPE) geomembrane, linear low density polyethylene (LLDPE) geomembrane, high-density polyethylene (HDPE) geomembrane;Aside from colorless and transparent raw material, you can made it into the black, green, blue, yellow, etc by adding different color masterbatch., also made into geomembrane with the black front and the blue back or other 2 different colors as required by customers.

Applications of GeomembraneLLDPE for Architectural Engineering

1.LDPE geomembrane is applicable to environmental protection and sanitation: such as landfill, sewage treatment plant, power plant adjustive pool, industrial, hospital solid waste;

2.LDPE geomembrane is applicable to hydraulic engineering: such as seepage control, plugging, reinforcement for rivers, lakes and reservoirs and dams, drainage seepage control, vertical core wall, slope protection, etc.

3. LDPE geomembrane's applications in municipal engineering: subway, underground works of the building, planting roof, roof garden, sewage pipe seepage control;

4. Polyethylene impermeable membrane is applicable to the garden: artificial lake, river, reservoir, golf course pond bottom, slope, green lawn waterproofing and damp-proofing;

5. High density polyethylene geomembrane is applicable to petrochemical industry: chemical plant, oil refinery, storage tank seepage control, chemical reaction cell, lining and secondary lining for sedimentation tank, etc.

6. Polyethylene geomembrane is applicable to mining: washing pool, soaking pool, the ash-field, dissolving pool, settling pool, yard, tailings substrates seepage control;

7. Low density polyethylene geomembrane for transport facilities: foundation reinforcement for the road, culvert seepage control;

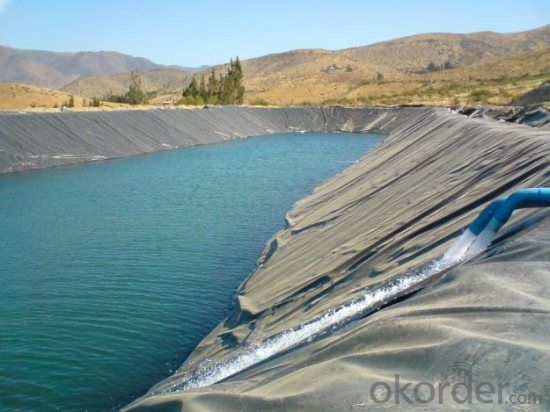

IMages of GeomembraneLLDPE for Architectural Engineering

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: What is the construction method of geomembrane for planting shallow water lotus?

- The bottom of the pond should be cleaned and tamped first, and then the HDPE geomembrane of 0.5 is laid on it. When the geomembrane is laid, patchwork should be avoided ane the edge joint lap width is 15-20 cm which should be welded by a climbing welder. Then you can put nutrition soil and water.

- Q: What are the safety considerations for working with geomembranes?

- When working with geomembranes, there are several safety considerations to keep in mind. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential hazards. Secondly, workers should be trained on proper handling and installation techniques to minimize the risk of accidents or injuries. This includes understanding how to safely handle and transport geomembrane rolls, as well as using proper tools and equipment for installation. Additionally, it is crucial to assess the work area for potential hazards such as uneven surfaces, sharp objects, or nearby machinery. Clearing the area of any potential dangers and ensuring proper signage and barricades are in place can help prevent accidents. Furthermore, working with geomembranes may involve the use of adhesives, solvents, or hot air guns. It is important to follow manufacturer's instructions and guidelines for the safe use of these materials, including proper ventilation and storage. Lastly, regular inspections and maintenance of equipment and tools should be carried out to ensure they are in good working condition. This can help prevent malfunctions or accidents during the installation process. Overall, prioritizing safety through proper training, the use of PPE, hazard assessments, and adherence to guidelines and protocols is essential for working with geomembranes.

- Q: How do geomembranes contribute to landfill gas collection systems?

- Geomembranes contribute to landfill gas collection systems by providing a barrier to prevent the escape of harmful gases from the landfill into the atmosphere. These impermeable membranes are installed as liners or covers to contain the waste and create a controlled environment for gas collection. The geomembranes help in directing the landfill gas to collection wells or pipes, where it can be safely extracted and utilized for energy generation or other purposes.

- Q: What are the codes for acceptance of constructional quality of concrete structures?

- 1, improve basic provisions of acceptance. 2, add provision of inspection lot expansion of certified products or continuous qualified products. 3, delete provisions for acceptance of template deismantle. 4, add provisions for acceptance of moulded rebar and other rebar new technologies. 5, add provisions for acceptance of unbonded prestressed steel fully enclosed waterproof performance. 6, improve provisions for site acceptance of premixed concrete. 7, , improve provisions for site acceptance of precast components. 8, add provisions for acceptance of objects which has deviation in structures position and dimension. 9, add a method of checking structural entity concrete strength through rebound-drilled core method.

- Q: Are geomembranes suitable for use in wildlife habitat restoration projects?

- Yes, geomembranes can be suitable for use in wildlife habitat restoration projects. They can help create or restore wetlands, ponds, or other water bodies by providing effective containment and water management. Geomembranes can prevent soil erosion, control water flow, and help maintain proper water levels, which are crucial for creating and maintaining diverse and healthy wildlife habitats. Additionally, they can aid in the remediation of contaminated sites, ensuring a safe environment for wildlife. However, it is important to consider the specific project requirements and ecological considerations to determine the suitability and potential impacts of using geomembranes in wildlife habitat restoration projects.

- Q: Imported geomembrane imported anti seepage film width.

- Now imported geomembrane 8 meters in width before we make drainage network.the length of Jianasuoma imported geomembrane is 8 meters in a bidding.

- Q: What is film mulching plywood?

- The advantages of film mulching template: large area. The maximum width is 2440*1220,915*1830mm, which reduced joint numbers, and improved the work efficiency of formwork. Do not warp, no deformation, no cracking, good water resistance, high turnover. Easy demoulding, only 1/7 of the steel mould. Light weight: It is more easy to be used in high-rise building and bridge construction. Use frequency: When properly stored and used, it can be used more than 12 times. Concrete pouring: Pouring surface is smooth and beautiful, leaving out twice plastering of walls, and it can be decorated directly which reduced 30% of duration. Corrosion resistance: Won't pollut concrete surface. Good thermal insulation: Conducive to winter construction, and can be used as bending plane template. Good performance in construction: Nails, saws, drilling and other properties are better than bamboo plywood. Small steel plate needs to be processed into template of various shapes according to construction.

- Q: How do geomembranes help with pond lining?

- Geomembranes help with pond lining by providing a durable and impermeable barrier that prevents water seepage and leakage. They act as a protective lining for the pond, ensuring that water stays contained and does not infiltrate the surrounding soil. Additionally, geomembranes help to prevent the loss of water through evaporation, thus reducing the need for frequent refilling.

- Q: what are the diamond film?

- "Diamond film" The name is really outdated because the market is disturbed. when this concept emerged, it has water prevent functions. Later on, the lens prices are getting lower and lower and the quality is getting bad.

- Q: What are the considerations for geomembrane installations in areas with high groundwater levels?

- When installing geomembranes in areas with high groundwater levels, there are several considerations that need to be taken into account. First and foremost, proper site investigation and assessment of the groundwater conditions must be conducted to determine the potential risks and challenges. The selection of an appropriate geomembrane material with high impermeability is crucial to prevent water seepage or leakage. Additionally, effective design and installation techniques such as proper anchoring and sealing methods should be employed to ensure the geomembrane remains intact and functional. Adequate drainage systems should be implemented to manage and control the groundwater levels, preventing excessive pressure buildup. Regular monitoring and maintenance are also essential to detect any potential issues early on and prevent failures. Overall, careful planning, material selection, design considerations, and ongoing maintenance are key factors in successful geomembrane installations in areas with high groundwater levels.

Send your message to us

Geomembrana Para Techos LLDPE 1.2mm para Ingeniería Arquitectónica

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords