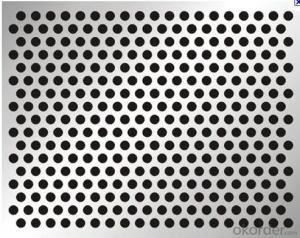

Custom Aluminum Sheets in Mm for Roof

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

- Q: Can 101 aluminum sheets be used in the production of decorative panels?

- Yes, 101 aluminum sheets can be used in the production of decorative panels. 101 aluminum is a commercially pure aluminum alloy known for its excellent formability and corrosion resistance. These characteristics make it suitable for various applications, including decorative panels. The aluminum sheets can be easily shaped, cut, and fabricated to create intricate designs and patterns for decorative purposes. Additionally, the corrosion resistance of 101 aluminum ensures that the panels will maintain their appearance over time, even in outdoor or high-moisture environments.

- Q: Explain the distinctions between aluminum sheets and aluminum foil in terms of thickness, uses, and properties.

- <p>Aluminum sheets and aluminum foil are both made from aluminum but differ in thickness and applications. Aluminum sheets are thicker and more rigid, typically used for construction, manufacturing, and as a packaging material. They offer better strength and durability. Aluminum foil, on the other hand, is very thin and flexible, commonly used for food packaging, cooking, and insulation. It's lightweight and has excellent heat and light reflection properties. Aluminum sheets are often anodized or coated for additional properties, while foil is valued for its purity and malleability.</p>

- Q: This question asks for an overview of the various types of coatings applied to aluminum profiles used in exterior cladding systems.

- <p>Aluminum profiles for exterior cladding are often coated to enhance their durability, weather resistance, and aesthetic appeal. Common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the aluminum surface. 2. Powder coating, a popular method that provides a durable and colorful finish. 3. Fluorocarbon coating, known for its excellent weathering and UV resistance. 4. PVDF (Polyvinylidene Fluoride) coating, highly resistant to chemicals and suitable for marine environments. 5. Electrophoretic coating, which offers a smooth, even finish. 6. Hot-dip galvanizing, a process that coats aluminum with a protective layer of zinc. Each coating type has specific advantages and is chosen based on the performance requirements and environmental conditions of the project.</p>

- Q: Hi everyone, I have this problem that I'm somewhat confused about. The problem is:An alloy of aluminum and magensium was treated with sodium hydroxide solution, in which only aluminum reacts to give hydrogen gas:2Al + 2NaOH + 6H20 --gt; 2NaAl(OH)4 + 3H2If a sample of alloy weighing 1.118 g gave 0.1068 g of hydrogen, what is the percentage aluminum in the alloy?How do I account for the magnesium and what stoichiometric relationships would I need to set-up? This is very confusing, but I appreciate the slightest of help on this!Thank you.

- You don't need to worry about the magnesium at all, because it doesn't enter into the reaction. You have a balanced equation for aluminium and hydrogen, and the data given are sufficient: From the equation, you know that 2 moles of aluminium produce 3 moles of H2. 0.1068 g of H2 were produced, so divide this by molecular mass of H2 (2.016) to determine the moles of H2 produced. You know that 3 moles of H2 would have been produced from 2 moles of Al. Therefore, multiply the moles of H2 by 2/3, to determine the moles of Al that were present. Now multiply this number by the atomic mass of Al, to determine the grams of Al. Now divide this number if grams by 1.118 and multiply by 100 to determine % Al present in the alloy.

- Q: Is it possible to use aluminum sheets in the manufacturing process of solar panels?

- <p>While aluminum sheets can be used in the construction of solar panels, they are not the primary material for making the solar cells themselves. Aluminum is typically used for the frame or backsheet to provide structural support and protection. The actual solar cells are made from materials like silicon, which is capable of converting sunlight into electricity. So, while aluminum plays a role in the assembly of solar panels, it is not used to create the photovoltaic cells that generate power.</p>

- Q: What are the different thicknesses available for aluminum sheet?

- Aluminum sheets are available in a variety of thicknesses, ranging from extremely thin to thick. The thickness of aluminum sheets is measured in gauge or millimeters (mm), with each gauge representing a specific thickness. The most common gauges for aluminum sheets include 22, 24, 26, 28, 30, and 32. These gauges correspond to thicknesses ranging from 0.0254 mm to 0.635 mm. Additionally, aluminum sheets can be found in thicker gauges, such as 16 gauge (1.29 mm) or even thicker for specialized applications. The choice of thickness depends on the intended use of the aluminum sheet, with thinner sheets often being used for lightweight applications like electronics or packaging, while thicker sheets are preferred for structural or industrial purposes.

- Q: What is the typical weldability of aluminum sheets?

- The typical weldability of aluminum sheets is considered to be excellent. Aluminum is known for its high weldability due to its low melting point and thermal conductivity. It can be easily joined using various welding techniques such as TIG (tungsten inert gas), MIG (metal inert gas), and even spot welding. The weldability of aluminum sheets is further enhanced by the use of filler materials specifically designed for aluminum welding. However, it is important to note that the weldability can vary depending on the alloy composition, thickness, and surface condition of the aluminum sheet.

- Q: If I were to make an aluminum mold and cover it with a release agent, could I cast aluminum into it? Or would the two parts fuse together? I'm trying to find an alternative to sand casting.Thank you!

- This may be a little more difficult but offers better detail than sand casting. Lost wax casting Investment or ceramic shell You can make molds to form the wax but investment or ceramic shell are destroyed in the process

- Q: So I got this stainless steel ring but I took it to this place and apparently its not stainless it's aliminum bc of how light it is but it's really hard so how could it be aluminum?

- Aluminum is a quite soft metal, but so is gold. It is true that aluminum is light in weight but magnesium is even lighter and is common enough that a ring could be made of it. Metals can be made harder by adding small amounts of other metals or even by the way it is heat treated. .

- Q: What is aluminium plate for?

- Two outdoor and indoor, outdoor curtain wall decoration, indoor ceiling (such as aluminum pinch plate, aluminum grille, aluminum hanging tablets, etc.), color diversity, but also can be made imitation wood grain, imitation marble and other colors, widely used

Send your message to us

Custom Aluminum Sheets in Mm for Roof

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords