Customizable Aluminum Sheets in Minnesota for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

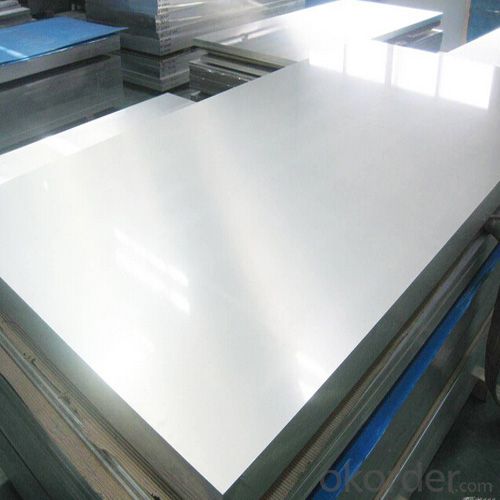

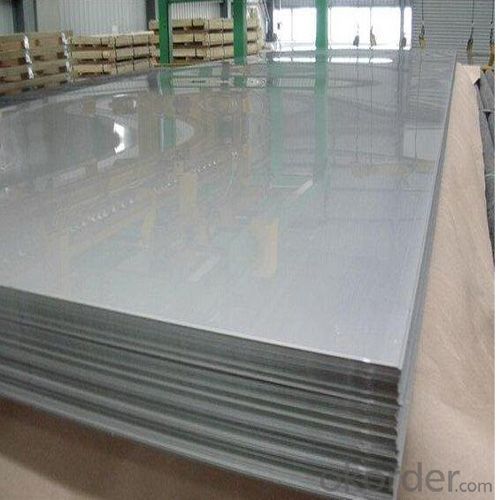

1.Structure of Customizable Aluminium Sheet Plate for Construction Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Customizable Aluminium Sheet Plate for Construction :

Low density, light in weight

Anti-corrosion

Strong

Malleable

Naturally good looking

Recyclable

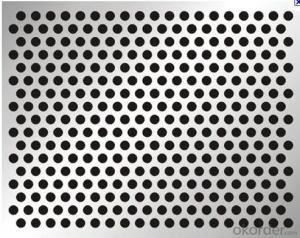

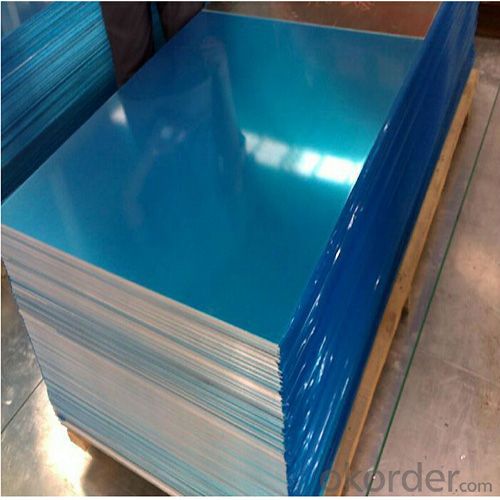

3. Customizable Aluminium Sheet Plate for Construction Images:

4. Customizable Aluminium Sheet Plate for Construction Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: This aluminum is on a mobile home. I trying to repaint it and there is alot of areas were rust has ate the metal away. Especially in the seams. How can I get rid of the rust that already exists and stop it from coming back.

- aluminum doesn't rust but it does corrode I think they make a navel jelly for aluminum they should sell it at the hardware store just follow the directions on the bottle

- Q: Can aluminum sheets be used for HVAC ductwork?

- Yes, aluminum sheets can be used for HVAC ductwork. Aluminum is a popular choice for ductwork due to its lightweight, corrosion-resistant, and durable properties. It is also easy to fabricate and install, making it suitable for various HVAC applications.

- Q: Inquire whether aluminum sheets are generally more costly compared to other sheet metal materials.

- <p>Aluminum sheets are not necessarily more expensive than other types of sheet metal. The cost can vary based on factors such as the current market price of the metal, the thickness and grade of the sheet, and the specific alloy used. Generally, aluminum is less expensive than metals like stainless steel or copper, but it can be more expensive than common metals like steel or iron. Prices fluctuate, so it's best to check current market prices for the most accurate comparison.</p>

- Q: Can aluminum sheets be used for heat sinks in LED lighting?

- Yes, aluminum sheets can be used for heat sinks in LED lighting. Aluminum is widely used in heat sink applications due to its excellent thermal conductivity and lightweight properties. It effectively dissipates heat generated by the LED, helping to maintain optimal operating temperatures and prolong the lifespan of the lighting system.

- Q: Are the aluminum sheets suitable for manufacturing aircraft wings?

- Indeed, aluminum sheets prove to be a fitting material for the production of aircraft wings. In the aerospace sector, aluminum is extensively utilized owing to its remarkable strength-to-weight ratio, ability to resist corrosion, and high thermal conductivity. These attributes render it an ideal option for fabricating aircraft components that are both lightweight and robust, such as wings. Aluminum sheets can be easily molded, fused, and processed, enabling the creation of intricate wing designs. Furthermore, the low density of aluminum aids in reducing the overall weight of the aircraft, thereby enhancing fuel efficiency and maneuverability. In summary, the utilization of aluminum sheets in the manufacture of aircraft wings is a prevalent and validated practice within the aviation industry.

- Q: Can aluminum sheet be used for architectural façade systems?

- Indeed, architectural façade systems can make use of aluminum sheet. The lightweight, durable, and corrosion-resistant properties of aluminum make it a favored option for building exteriors. It can be easily manipulated and fabricated into a plethora of shapes and sizes, thus rendering it suitable for the creation of intricate designs and architectural elements. Moreover, aluminum can be coated or treated in various ways to enhance its appearance and shield it from weathering. The versatility, aesthetic appeal, and long-term cost-effectiveness of aluminum sheet make it an exceptional selection for architectural façade systems.

- Q: Are 101 aluminum sheets suitable for high-temperature applications?

- No, 101 aluminum sheets are not suitable for high-temperature applications. 101 aluminum is a pure aluminum alloy with excellent corrosion resistance and good formability, but it has a low melting point of 660 degrees Celsius (1220 degrees Fahrenheit). High-temperature applications typically require materials with higher melting points and better heat resistance, such as stainless steel or high-temperature alloys. Using 101 aluminum sheets in high-temperature environments could result in deformation, melting, or failure of the material, which could compromise the integrity and safety of the application.

- Q: What are the different alloys used in aluminum sheets?

- There are several different alloys used in aluminum sheets, each with its own unique properties and characteristics. Some of the commonly used alloys are: 1. 1100: This alloy is known for its excellent corrosion resistance and high electrical conductivity. It is often used in applications requiring a high level of formability and weldability, such as food packaging and electrical conductors. 2. 3003: This alloy is widely used in various applications due to its good formability, moderate strength, and excellent corrosion resistance. It is commonly used in cooking utensils, chemical equipment, and general sheet metal work. 3. 5052: This alloy is known for its high strength and good corrosion resistance. It is often used in marine applications, as well as in aircraft fuel tanks and automotive parts. 4. 6061: This alloy is one of the most versatile and widely used aluminum alloys. It offers excellent corrosion resistance, good weldability, and moderate strength. It is commonly used in structural components, such as frames and railings, as well as in automotive parts and aerospace applications. 5. 7075: This alloy is known for its high strength-to-weight ratio and excellent fatigue resistance. It is often used in applications requiring extreme strength, such as aircraft and aerospace components, as well as in high-performance sporting goods. These are just a few examples of the many different alloys used in aluminum sheets. The choice of alloy depends on the specific application requirements, such as strength, corrosion resistance, formability, and weldability.

- Q: Is it possible to utilize aluminum sheets for the construction of outdoor advertising billboards?

- <p>Yes, aluminum sheets are commonly used for outdoor advertising billboards due to their durability, lightweight, and resistance to weather conditions. They are easy to install, maintain, and can be printed with high-quality graphics. Additionally, aluminum's corrosion resistance makes it a sustainable choice for long-term outdoor use.</p>

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, you can use aluminum sheets to create a green building. Aluminum is a sustainable material due to its recyclability and energy efficiency in production. It has a high recycled content rate, reducing the need for raw material extraction. Additionally, aluminum's lightweight nature can lead to reduced energy consumption in transportation and construction. Its durability and resistance to corrosion can extend the life of a building, further contributing to sustainability. However, it's important to consider the entire lifecycle impact, including the energy used in aluminum production, and to source aluminum responsibly to ensure a truly green building.</p>

Send your message to us

Customizable Aluminum Sheets in Minnesota for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords