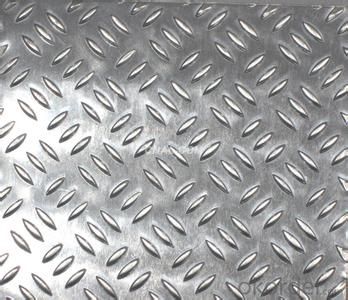

Painted Aluminum Sheets Minnesota - Checkered Aluminium Sheet-AA3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description:

1. Specifications of Aluminum Checkered Sheet

| MAIN SPECIFICATION OF ALUMINUM CHECKERED SHEET | |

| Alloy | AA1XXX (AA1050, AA1060, AA1070, AA1100 etc.) |

| AA3XXX (AA3003, AA3004, AA3005, AA3105 etc.) | |

| AA5XXX(AA5052) | |

| | |

| Temper | H14,H18,H24, H26, H32 |

| Thickness | 0.2mm-100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

| Special specification is available on customer's requirement | |

2. Usage/Applications of Aluminum Checkered Sheet

The embossed aluminum sheet are widely used for decorative purposes in construction, packing and appliance. It is also very commonly used for anti-splippery purposes in vehicles and public places.

3. Packing & Delivery of Aluminum Checkered Sheet

Packaging: Seaworth package

Shipment: The goods will be delivered in not more than 40 days after getting the buyer's payment.

- Q: Can aluminum sheet withstand heavy loads?

- Indeed, the durability of aluminum sheet is such that it can endure substantial loads. Renowned for its exceptional strength-to-weight ratio, aluminum proves to be an exceptional selection for endeavors necessitating both resilience and load-bearing capacities. Notably prevalent in sectors like aerospace, automotive, construction, and marine, aluminum sheets are frequently employed in scenarios involving weighty burdens. Moreover, the innate corrosion resistance of aluminum further fortifies its capacity to bear heavy loads for extensive durations. Nevertheless, it is crucial to take into account the precise grade and thickness of the aluminum sheet, as diverse alloys and thicknesses yield differing load capacities.

- Q: Can the aluminum sheets be used for manufacturing food packaging?

- Yes, aluminum sheets can be used for manufacturing food packaging. Aluminum is a popular choice for food packaging due to its various properties. It is lightweight, resistant to corrosion, and has excellent heat conductivity. These qualities make it suitable for preserving the freshness and quality of food products. Additionally, aluminum is impermeable to light, moisture, and oxygen, which helps in extending the shelf life of food. Furthermore, aluminum sheets can be easily molded into different shapes and sizes, allowing for customized packaging solutions. Overall, aluminum sheets are commonly used in the food packaging industry due to their versatility, durability, and ability to maintain the safety and integrity of food products.

- Q: Is it possible to recycle aluminum sheets while maintaining their quality?

- <p>Yes, aluminum sheets can be recycled without damaging their quality. The recycling process for aluminum is highly efficient, and it retains its properties even after multiple recycling cycles. Aluminum recycling involves melting the scrap material, which requires only 5% of the energy needed to produce new aluminum from raw materials. This process results in minimal loss of material, and the recycled aluminum maintains its strength and durability, making it suitable for various applications just like new aluminum.</p>

- Q: Is it possible to use aluminum sheets in environments with low temperatures?

- <p>Yes, aluminum sheets can be used in cold climates. Aluminum has excellent corrosion resistance and maintains its strength in low temperatures, making it suitable for use in cold environments. It does not rust or corrode easily, which is beneficial in harsh weather conditions. However, it's important to consider thermal expansion and contraction, as aluminum expands and contracts more than some other materials. Proper installation and design considerations are necessary to account for these properties in cold climates.</p>

- Q: Can 101 aluminum sheets be customized in terms of size and thickness?

- Certainly! It is possible to customize the size and thickness of 101 aluminum sheets. One can achieve the desired size and thickness by employing diverse cutting methods like shearing, sawing, or laser cutting. Moreover, rolling or stretching the aluminum sheets can also result in the desired thickness. By personalizing the size and thickness of aluminum sheets, they can be tailored to meet specific applications or requirements.

- Q: Are aluminum sheets fire resistant?

- Yes, aluminum sheets are fire resistant.

- Q: Are aluminum sheets suitable for signage?

- Signage can greatly benefit from the use of aluminum sheets. This material is known for its versatility and numerous advantages when it comes to signage applications. With its lightweight nature, durability, and resistance to corrosion, aluminum is an excellent choice for both indoor and outdoor signage. Regardless of weather conditions, be it rain, snow, or intense UV exposure, aluminum sheets will not deteriorate or fade. Furthermore, aluminum sheets are easy to work with, providing a wide range of customization options such as embossing, engraving, and digital printing. Not only are they cost-effective, but they also have a long lifespan, ensuring that signage remains in top-notch condition for extended periods. Ultimately, due to their durability, versatility, and aesthetic appeal, aluminum sheets are a preferred choice for signage.

- Q: Aluminum does not react with oxygen.Aluminum is a very unreactive metal.Aluminum forms a tough protective coating with oxygen.Aluminum tarnishes instead of corroding.If you could explain why it would be helpful!

- Aluminum forms a tough protective coating with oxygen. The coating of aluminum oxide is not porous enough to let further oxygen through it, so the aluminum underneath is protected from further corrosion.

- Q: Can the aluminum sheets be used in food or beverage processing industries?

- Yes, aluminum sheets can be used in food or beverage processing industries. Aluminum is a non-toxic material, and it is widely used in the food and beverage industry due to its excellent properties. Aluminum sheets are resistant to corrosion, lightweight, and have good thermal conductivity. These properties make them ideal for various applications in food and beverage processing industries, such as food packaging, cooking utensils, storage containers, and beverage cans. Additionally, aluminum is a sustainable material as it can be recycled, which further enhances its suitability for use in these industries.

- Q: Are aluminum sheets resistant to chemicals?

- Aluminum sheets, in general, possess resistance to a wide range of chemicals. This is due to the presence of a natural oxide layer on the surface of aluminum, which acts as a protective shield against corrosion and chemical reactions. The stability of this oxide layer enables it to withstand the effects of most acids, alkalis, and organic solvents. However, it should be noted that certain chemicals, such as strong acids or bases, as well as some halogenated compounds, have the capacity to corrode aluminum. Moreover, prolonged exposure to particular chemicals or extreme conditions may compromise the integrity of the oxide layer, rendering aluminum more susceptible to corrosion. Consequently, when considering the use of aluminum sheets in specific applications, it is crucial to carefully evaluate the chemical environment and potential interactions.

Send your message to us

Painted Aluminum Sheets Minnesota - Checkered Aluminium Sheet-AA3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords