Stainless Steel Plate 304L with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

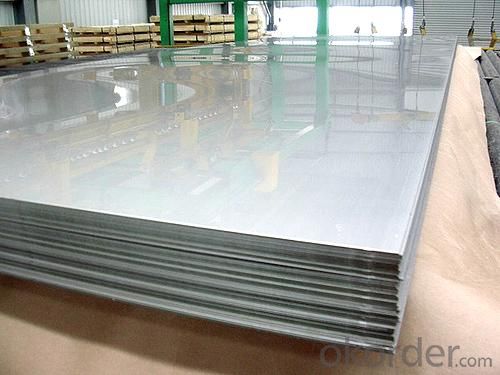

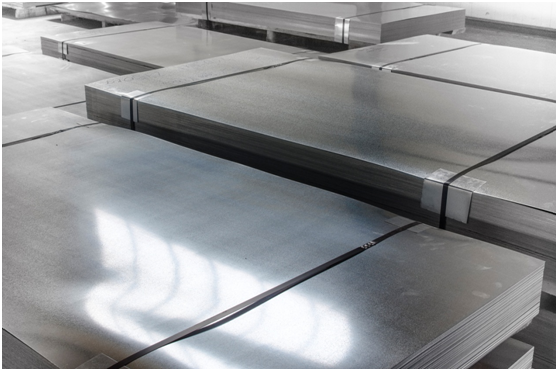

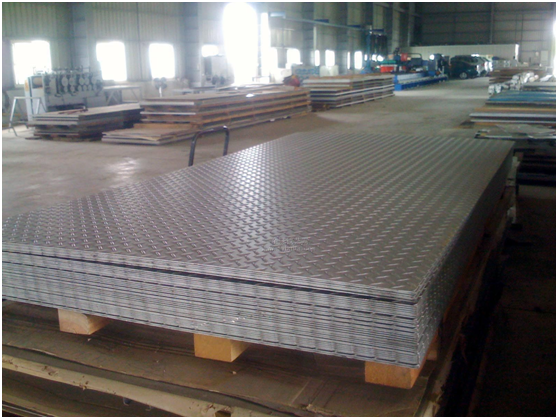

Stainless Steel Plate 304L with Surface Treatment

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

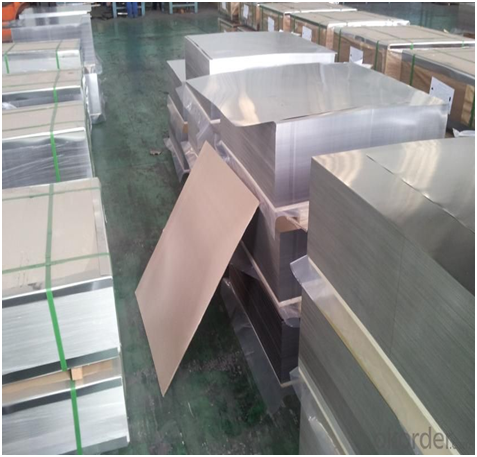

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Several processing techniques of colored stainless steel

- Etched series, etched images, visible pictures. After etching, the color or color can be etched and etched. The color stainless steel etching is made by etching various patterns on the surface of the material by chemical method. The 8K mirror panel or drawing plate plate, etching treatment, on the surface of the deep processing, can be partial and local lines, drawing, inlaid with gold and titanium and other kinds of complex process, realize the pattern of light and colorful effect. Etching stainless steel including color stainless steel etching, a variety of patterns, for the selection of color: titanium black (Hei Tai), sky blue, titanium gold, sapphire blue, brown, brown, purple, bronze, green bronze, champagne gold, rose gold, purple, white, green, green, suitable for: star hotel KTV, a large shopping mall, senior entertainment etc.. Can also be customized according to customer drawings and requirements, but the need for template fees.

- Q: How do you remove scratches from stainless steel sheets?

- To remove scratches from stainless steel sheets, there are a few methods you can try. First, you can start by using a non-abrasive cleaner or a mild detergent mixed with warm water. Apply the solution to the scratched area using a soft cloth or sponge, and gently rub in a circular motion. Rinse the area thoroughly and dry it with a clean cloth. If the scratches are still visible, you can try using a stainless steel scratch removal kit. These kits often contain a polishing compound specifically designed for stainless steel. Apply the compound to the scratched area and use a soft cloth to buff the surface in the direction of the grain. Continue buffing until the scratches are no longer visible. For deeper scratches, you may need to use a fine-grit sandpaper or a stainless steel scratch repair pen. Start by lightly sanding the scratched area in the direction of the grain. Be careful not to apply too much pressure, as this can damage the surface. After sanding, clean the area thoroughly and use a polishing compound to restore the shine. It's important to note that these methods may not completely remove deep scratches, and in some cases, a professional repair may be necessary. Additionally, always test any cleaning or repair method on a small, inconspicuous area before applying it to the entire surface to ensure it does not cause further damage.

- Q: Are stainless steel sheets suitable for automotive exhaust systems?

- Certainly, stainless steel sheets are indeed appropriate for automotive exhaust systems. Due to their remarkable resistance to corrosion, heat, and vibration, stainless steel is highly sought after as a material for exhaust systems. It possesses the ability to endure the extreme temperatures and harsh conditions that exhaust systems encounter, rendering it a robust and enduring option. Moreover, stainless steel exhibits exceptional thermal conductivity, facilitating the efficient dissipation of heat. Additionally, it provides good formability, granting manufacturers the flexibility to design and mold the exhaust components according to their requirements. All in all, stainless steel sheets emerge as a dependable and widely favored selection for automotive exhaust systems.

- Q: Are stainless steel sheets suitable for chemical transport containers?

- Indeed, chemical transport containers can rely on stainless steel sheets. Renowned for its exceptional resistance to corrosion, stainless steel proves highly appropriate for chemical transportation. Its ability to withstand numerous acids, alkalis, and corrosive substances guarantees the preservation and purity of the chemicals throughout transit. Moreover, stainless steel sheets boast durability and strength, delivering structural integrity to the containers and ensuring the secure transportation of chemicals.

- Q: Are stainless steel sheets suitable for outdoor sculptures or decorative pieces?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures or decorative pieces. Stainless steel is known for its durability, resistance to corrosion, and ability to withstand harsh weather conditions, making it an ideal choice for outdoor applications. Additionally, its sleek and polished appearance adds a touch of elegance and modernity to any outdoor space.

- Q: Can stainless steel sheets be used in architectural applications?

- Yes, stainless steel sheets can be used in architectural applications. Stainless steel is a versatile material that offers durability, corrosion resistance, and aesthetic appeal, making it suitable for various architectural purposes such as cladding, roofing, decorative elements, and structural components. Its sleek, modern look and ability to withstand harsh environmental conditions make stainless steel sheets a popular choice in the construction industry.

- Q: Are stainless steel sheets suitable for medical equipment or devices?

- Yes, stainless steel sheets are commonly used in the manufacturing of medical equipment or devices due to their excellent corrosion resistance, durability, ease of cleaning, and ability to withstand sterilization processes.

- Q: Can stainless steel sheets be used for elevator handrails?

- Indeed, elevator handrails can utilize stainless steel sheets. The utilization of stainless steel for handrails is prevalent owing to its endurance, robustness, and immunity to rust. Elevator handrails endure incessant usage and exposure to diverse elements, rendering stainless steel an exemplary selection. Moreover, stainless steel can be effortlessly cleansed and upheld, guaranteeing a sanitary and visually pleasing atmosphere for elevator occupants.

- Q: How do you prevent staining on stainless steel sheets?

- To prevent staining on stainless steel sheets, it is important to regularly clean and maintain them. This can be done by using non-abrasive cleaners specifically designed for stainless steel, avoiding harsh chemicals and abrasive materials that can scratch the surface. Additionally, wiping away spills or moisture promptly and drying the sheets thoroughly after cleaning can help prevent staining. Using protective coatings or sealants specifically made for stainless steel can also offer an extra layer of protection against staining.

- Q: What brand of stainless steel plate is good?

- Stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, corrosion of acid, alkaline gas, solution and other medium.

Send your message to us

Stainless Steel Plate 304L with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords