Zinc Galvanized Corrugated Steel Iron Zinc Roof Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

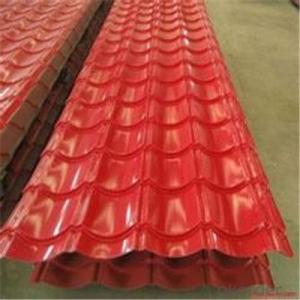

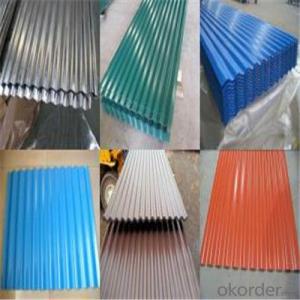

Description of Prepainted Corrugated Iron Sheet:

1. Hot-dipped galvanized

2. Color: All RAL color

3. Thickness: 0.23-1.0MM

4. Developed Width: 600mm to1200mm

Specifications of Prepainted Corrugated Iron Sheet:

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

Features of Prepainted Corrugated Iron Sheet:

(1) Novel and beautiful modeling , rich luster, strong adornment sex, flexible in combination, can express different architectural styles;

(2) Light weight (6 ~ 10 kg/m squared) high strength (yield strength 250 ~ 550 mpa) fine skin stiffness,fine seismic performance of waterproofing agent;

Images of Prepainted Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Can steel sheets be used for manufacturing security doors?

- Indeed, security doors can be manufactured using steel sheets. Steel, being a robust and long-lasting material, offers exceptional security and safeguarding. It possesses the ability to withstand forced entry attempts and provides resistance against break-ins. Due to their remarkable tensile strength, steel sheets are frequently employed in the construction of security doors as they are difficult to bend or break. Moreover, steel doors can be further reinforced with various additional features, including multiple locks, deadbolts, and security bars, to enhance their security capabilities. All in all, steel sheets serve as a dependable option for the production of security doors.

- Q: What are the common sizes of steel sheets available?

- Steel sheets are available in a variety of sizes to meet the diverse needs of different industries and applications. The common sizes of steel sheets can vary depending on the manufacturer and the specific requirements of the customer. However, there are some standard sizes that are widely available in the market. The most common sizes of steel sheets include: 1. 4 feet by 8 feet: This is one of the most popular sizes and is widely used in construction, manufacturing, and automotive industries. It provides a large surface area for various applications, including roofing, siding, and fabrication. 2. 4 feet by 10 feet: This size is similar to the 4 feet by 8 feet sheets but offers a larger surface area, making it suitable for larger projects that require more material. 3. 5 feet by 10 feet: This size provides an even larger surface area than the 4 feet by 10 feet sheets, making it ideal for industrial applications that require extensive coverage. 4. 6 feet by 12 feet: This is a larger size that is commonly used in heavy-duty applications, such as shipbuilding, construction of large structures, and industrial machinery. It's important to note that these are just some of the common sizes available, and there are many other sizes offered by manufacturers to cater to specific requirements. Additionally, steel sheets can also be custom-cut to fit specific dimensions, allowing for greater flexibility and tailoring to individual project needs.

- Q: Can steel sheets be used for industrial machinery?

- Yes, steel sheets can definitely be used for industrial machinery. Steel is a widely used material in the manufacturing industry due to its exceptional strength, durability, and versatility. Steel sheets can be formed, machined, and welded into various shapes and sizes to meet the specific requirements of industrial machinery. Additionally, steel sheets offer excellent resistance to corrosion, impact, and extreme temperatures, making them ideal for heavy-duty applications. The use of steel sheets in industrial machinery ensures structural integrity, longevity, and enhanced performance, making it a preferred choice for many manufacturers in the industry.

- Q: Can steel sheets withstand extreme temperatures?

- Indeed, extreme temperatures pose no challenge to steel sheets. Renowned for its remarkable melting point of approximately 1370°C (2500°F), steel proves itself as an ideal choice for environments characterized by intense heat, including furnaces, kilns, and industrial ovens. Moreover, steel exhibits exceptional thermal conductivity, enabling efficient heat transfer while effectively withstanding the expansion and contraction caused by temperature fluctuations. Thanks to these exceptional attributes, steel sheets remain impervious to warping, cracking, and other structural impairments often encountered in extreme temperature scenarios.

- Q: What are the different surface protection methods for steel sheets?

- Some common surface protection methods for steel sheets include galvanization, powder coating, painting, and plating. Galvanization involves coating the steel with a layer of zinc to protect it from corrosion. Powder coating involves applying a dry powder to the steel and then curing it under heat to form a protective layer. Painting involves applying a layer of paint to the steel to provide both protection and aesthetic appeal. Plating involves electroplating the steel with a layer of another metal, such as chrome or nickel, to enhance its corrosion resistance and appearance.

- Q: Can steel sheets be used for mezzanine floors?

- Yes, steel sheets can be used for mezzanine floors. Steel is a commonly used material for constructing mezzanine floors due to its strength, durability, and ability to support heavy loads. Steel sheets can be used as the primary flooring material or as a subflooring layer, providing a stable and secure platform for various applications.

- Q: How are steel sheets measured?

- Steel sheets are typically measured by their thickness, width, and length. The thickness is measured in gauges or millimeters, while the width and length are measured in inches or feet.

- Q: Are the steel sheets suitable for shipbuilding?

- Yes, steel sheets are highly suitable for shipbuilding. Steel is a versatile and durable material that possesses excellent properties for marine applications. It has a high strength-to-weight ratio, allowing for the construction of robust and sturdy vessels while keeping the overall weight low. Steel sheets also have high tensile strength, which ensures the ship's structural integrity and resistance to forces exerted by waves, wind, and other external factors. Additionally, steel is highly resistant to corrosion, making it ideal for withstanding the harsh saltwater environment. Its fire-resistant properties further enhance the safety of ships. Given these advantages, steel sheets are widely used in shipbuilding and have proven to be reliable and efficient in constructing various types of vessels, from cargo ships to cruise liners and naval warships.

- Q: Can steel sheets be used for sculptures and artwork?

- Yes, steel sheets can be used for sculptures and artwork. Steel is a versatile material that can be shaped, welded, and manipulated into various forms, making it suitable for creating sculptures and other artistic pieces. Its strength and durability also make it ideal for outdoor installations.

- Q: What are the different jointing methods for steel sheets?

- Steel sheets can be joined using various methods, depending on specific requirements and applications. Common jointing methods for steel sheets include welding, bolting, riveting, adhesive bonding, and mechanical fasteners. Welding is widely used, involving melting the steel sheet edges and joining them by applying heat and pressure. Different welding techniques, like arc welding, gas welding, or laser welding, can be used depending on the steel sheet thickness and type. Bolting involves using bolts and nuts to join steel sheets together. This method is suitable for easily disassembling or replacing joints and can be used for both permanent and temporary connections. Riveting is another method, using rivets to join steel sheets. Rivets are cylindrical metal pins inserted through holes in the sheets and deformed to secure the joint. Riveting is ideal for applications requiring high shear strength. Adhesive bonding uses specialized adhesives to join steel sheets. This method provides a strong and durable joint, suitable when welding or other mechanical jointing methods are not suitable. Adhesive bonding also distributes stress more uniformly across the joint. Mechanical fasteners, like clips, clamps, or brackets, can be used to join steel sheets. These fasteners offer a secure and reliable connection without requiring welding or other permanent jointing methods. They are commonly used when ease of assembly and disassembly is necessary. In conclusion, the choice of jointing method for steel sheets depends on factors such as the application, desired strength and durability, and ease of assembly and disassembly. Careful consideration of these factors is essential to ensure a successful and reliable connection.

Send your message to us

Zinc Galvanized Corrugated Steel Iron Zinc Roof Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords