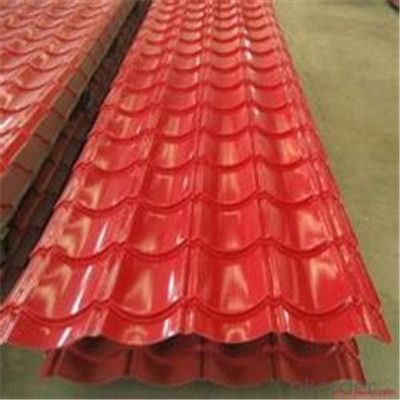

Zinc Galvanized Corrugated Steel Iron Zinc Roof Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000345 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

Minimum yield strength of 550 MPa ensures required strength for roofing application

Accurate thickness, width and length gives a perfect fit for any roof

Wider valley ensures higher water discharge in case of heavy rains

Specifications of Corrugated Iron Sheet:

1) Chemical Composition: 55% Aluminum, 43.4% Zinc, 1.6% Silicon

2) Substrate: Galvalume steel sheet & Pre-painted galvalume steel sheet

3) Standard: JIS3321/ASTM A792M

4) Thickness: 0.16mm-2.0mm, all available

5) Width: 600mm-1250mm, all available

Features of Corrugated Iron Sheet:

Raw material width 762mm, after corrugated width 665mm: 9 waves.

Raw material width 914mm ,after corrugated width 800mm:11 waves.

Raw material width 1000mm, after corrugated 890mm or 900mm :12 or 14 waves. as customer requirement

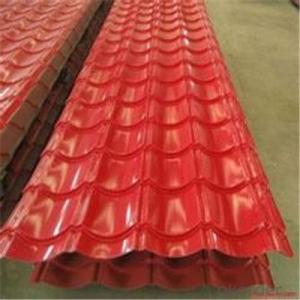

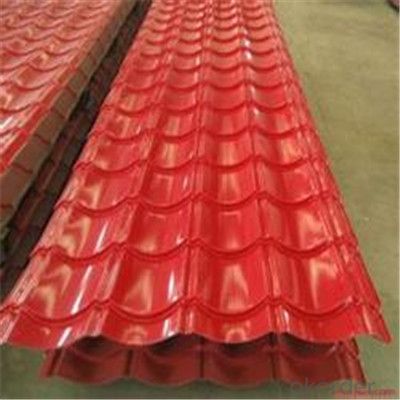

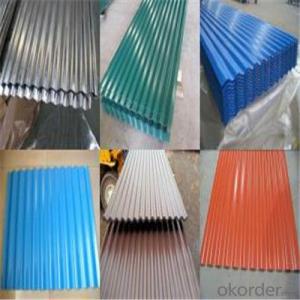

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Are the steel sheets resistant to bending or warping?

- Indeed, steel sheets exhibit exceptional resistance against bending or warping. Renowned for its robustness and longevity, steel remains a favored option across diverse applications that demand unwavering resistance to bending or warping. The innate characteristics of steel, such as its remarkable tensile strength and stiffness, enable it to endure substantial loads and pressure while retaining its original shape. Furthermore, steel's uniform and homogeneous structure guarantee steadfast resistance to bending or warping, cementing its reputation as a dependable substance for endeavors necessitating stability and structural soundness.

- Q: What are the safety considerations when working with steel sheets?

- When working with steel sheets, some safety considerations include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toe boots to protect against cuts, burns, and falling objects. It is important to handle steel sheets with caution to avoid injury from sharp edges or corners. Additionally, ensuring proper ventilation in the work area is important to minimize exposure to potentially harmful fumes or dust particles. Regularly inspecting equipment and tools for any defects or damages is crucial to prevent accidents. Finally, following proper lifting techniques and using mechanical aids when necessary can help prevent strains or other musculoskeletal injuries.

- Q: Are steel sheets suitable for sports stadiums or arenas?

- Yes, steel sheets are suitable for sports stadiums or arenas. Steel sheets offer high strength and durability, making them a reliable choice for constructing structures that can withstand heavy loads and harsh weather conditions. Additionally, steel sheets can be easily fabricated and customized to meet the specific design and architectural requirements of sports stadiums and arenas.

- Q: What is the process of forming corrugated steel sheets?

- The process of forming corrugated steel sheets involves passing a flat steel sheet through a series of rolling mills equipped with corrugating rolls. These rolls have a pattern of ridges and grooves that shape the steel sheet into a wavy or corrugated form. The sheet is fed into the first set of rolls, which press the ridges into the sheet, and then it goes through subsequent sets of rolls to further refine the corrugations. This process creates strength and rigidity in the steel sheet, making it suitable for various applications in construction, roofing, and packaging industries.

- Q: Can steel sheets be used for water tanks or storage containers?

- Yes, steel sheets can be used for water tanks or storage containers. Steel is a durable and strong material that is often used in construction and manufacturing industries. It is resistant to corrosion and leakage, making it an ideal choice for holding and storing water or other substances. Additionally, steel sheets can be easily fabricated and assembled into various shapes and sizes to meet specific requirements for water tanks or storage containers.

- Q: What is the average price of a steel sheet?

- The average price of a steel sheet can vary depending on various factors such as size, thickness, quality, and market conditions. Therefore, it is difficult to provide an exact average price without specific details.

- Q: How do steel sheets perform in terms of abrasion resistance?

- Steel sheets generally have good abrasion resistance due to their hardness and durability. They can withstand friction and wear caused by rubbing or scraping against other surfaces, making them suitable for applications requiring resistance to wear, such as in construction, manufacturing, and automotive industries.

- Q: What's the corrosion resistance of hot-dip galvanized steel sheet?

- The corrosion resistance of galvanized steel sheet in natural environment is acceptable. The biochemical pond in the sewage treatment plant is strong in acidity, and the zinc is not acid resistant. It is very different from the galvanized sheet with the uncoated steel sheet.

- Q: Can steel sheets be used for automotive body panels?

- Yes, steel sheets can be used for automotive body panels. Steel is a common material choice for car body panels due to its strength, durability, and ability to withstand impact. It provides structural integrity and protection to the vehicle's occupants while also allowing for customization and design flexibility.

- Q: How do steel sheets handle expansion and contraction?

- Steel sheets handle expansion and contraction by allowing enough flexibility to accommodate changes in temperature. This is achieved through the inherent ductility and elasticity of steel, which enables it to expand and contract without significant deformation or damage. Additionally, steel sheets may be designed with specific expansion joints or gaps to further accommodate thermal changes and prevent buckling or warping.

Send your message to us

Zinc Galvanized Corrugated Steel Iron Zinc Roof Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000345 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords