Large two-platen (Direct Hydraulic Clamping) Injection Moulding Machines

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 SET unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Description of PLASTIC INJECTION MOLDING MACHINE-C SERIES

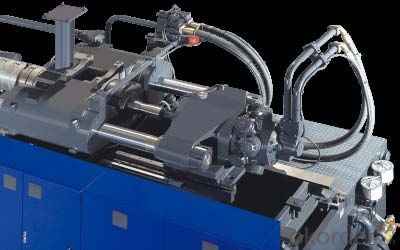

128J full hydraulic two-platen injection molding machine is special designed for plastic injection moulding.

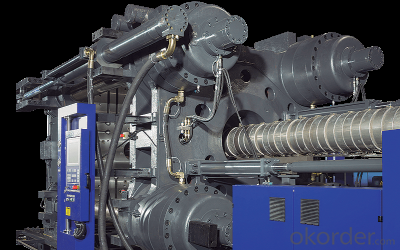

Full hydraulic two-platen injection molding machine for plastic, relying on independent intellectual property rights, make full use of the internal groups advanced technology HOYEAelectrohydraulic control,HOPEA(microcomputer frequency Conversion control) and precision injection molding machine developed independently by injection molding machine experienced engineers in our Machinery. With the latest European Hydraulic Design Concept, Machinery electro-hydraulic control specialists make great efforts to build the plastic injection equipment with environment-friendly and energy-saving.

Advantage of PLASTIC INJECTION MOLDING MACHINE-C SERIES

Super-Large space, we can make machine as the requirement of customers products, with parameters strong adaptability.

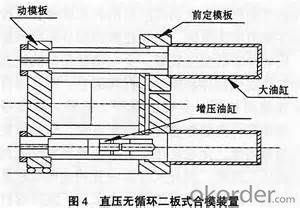

Short clamping stroke line, is only the distance between main moving platen and fixed platen, mould- clamping is high rigidity and precision.

Main moving platen adopts oil-less self-lubricating copper sets guide, ensure clean production environment. Support sliding feet can choose linear slide way guide, which greatly enhance the rigidity of clamping unit and service life of mould..

Using the latest German sealing technologies and products, ensure the sealing performance high.

Hydraulic system adopts proportional integrated instrument control system to ensure the mould transfer rapidly, stably.

Electrical system uses Siemens controller, with high speed, good stability, high performance and good scalability.

Specification of PLASTIC INJECTION MOLDING MACHINE-C SERIES

Item | Unit | Parameter | ||

Screw no | A | B | C | |

Screw Dia | mm | 38 | 42 | 45 |

Screw LD ratio | 23.2 | 21 | 19.6 | |

Theoretical capacity | cm3 | 209 | 256 | 294 |

Injection weight | g | 190 | 233 | 267 |

Injection Pressure | MPa | 243 | 199 | 173 |

Injection rate | g/s | 100.9 | 123 | 141.2 |

Plasticizing capacity | g/s | 14.7 | 18.2 | 20.6 |

Max. screw speed | rpm | 200 | ||

Clamping force | kN | 1280 | ||

Moving mould distance | mm | 560 | ||

Tie bar spacing | mm | 420×420 | ||

Max.Daylight | mm | 730 | ||

Min. mould thickness | mm | 170 | ||

Ejector stroke | mm | 150 | ||

Ejector force | kN | 41 | ||

Ejector bar amount | 5 | |||

Max.pump pressure | MPa | 17.5 | ||

Pump motor power | kW | 15 | ||

Heating power | kW | 7.5 | ||

External dimension | mm3 | 4500×1600×2100 | ||

Weight | Kg | 5500 | ||

Material cylinder capacity | L | 25 | ||

Oil tank capacity | L | 265 | ||

Package of PLASTIC INJECTION MOLDING MACHINE-C SERIES

Wooden box packed, suitable for train or sea worthy delivery.

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: PPO plastic mold commonly used steel processing?

- Application range6 polyphenylene ether is high strength engineering plastics development 60s of this century, it has high mechanical strength and creep resistance; excellent electrical properties, high temperature to 120 DEG C, and in a wide temperature range, stable size, mechanical properties and electrical properties change little; absorption of water vapor is very small. Cooking. Widely used in electronic, electrical components, medical equipment, cameras and office equipment, and so onCommon problem7 injection molding process characteristics and process parameters of modified polyphenylene oxidePolyphenylene oxide (also known as: polyphenylene oxide) [PPO] has good chemical stability, low creep, aging resistance, and it is not easy to burn. Because of its good water resistance, polyphenylene oxide is widely used as an engineering plastic.The major disadvantages of polyphenylene oxide are: poor flowability of melt, difficulty in forming process, tendency of cross linking, expensive price, easy stress cracking and unstable impact strength.

- Q: What are the features of plastic injection gears and machined plastic gears?

- Injection of better, smooth finish, smoothness can be done on the mold, the strength is also good. When machining, some of the transmission, the edge may be very difficult to process, very beautiful

- Q: Laizhou plastic processing plastic machinery and equipment, which is more reliable, relatively good?

- In contrast to many manufacturers of plastic processing equipment, more important is environmental protection, there is calm in the future, if you want to buy the equipment you can go to Laizhou city to take a look at the field, there are a lot of home doing well, you have this problem too vague, but also do not know you to play some bottom in figure what product, change a problem to try again

- Q: Would like to ask a few questions?1, waste plastics need to go through a few devices or steps to become plastic particles2, how much would it cost for the whole set of plastic particles? (I want to get a small wire first)3, if the equipment, plastic material can be any processing?4, is there any pollution in the whole process?.5, how about this prospect this year?Please have experienced predecessors to give some experience

- 1, plastic pellet production equipment need: crushing machine, cleaning machine, dewatering machine, feeding machine, exhaust type extruder, granulator etc.. What do you look at the material, the demand for automation which decided to do good on machinery, extruder Jiaqieli machine is good.2, the whole set can be between 2-3 and 20-30 000.3, equipment is not what material can do is do what you don't need not yield white, but in general a set of general plastic can do.4, the entire process will have air pollution, dirty cleaning, there will be water pollution.5, this year to do this prospect is not good! What line is it about now?.

- Q: I would like to ask you how to produce plastic products, the need for mold, but also the need for large machinery, thank you all

- It depends on what kind of plastic products you make General use of the daily use of injection molding machines, water pipes, profiles, sheets need extruder, film type needs blowing machine, bottles need blowing machine, no matter which kind of mold is needed.

- Q: What kind of equipment does the plastic product factory need?

- Like universal printer, you can achieve this effect. In some plastic shell, plastic, plastic stationery and other top brands.

- Q: ABS plastic processing flow

- ManufacturabilityABS is an amorphous polymer with no apparent melting point. Because of its grades, grades, in the injection molding process should be based on the different grades to formulate the appropriate process parameters, generally in 160X: above, 270C can be formed below. Because the temperature is too high, there is a tendency to destroy the rubbery phase in ABS and begin to decompose over ZTOC. In the process of molding, ABS has better thermal stability, wider range of choice, and it is difficult to degrade or decompose. Moreover, ABS melt viscosity is moderate, its fluidity is better than the polyvinyl chloride, the polycarbonate and so on, moreover, the melt cooling solidification speed is relatively quick, generally in 5 ~ 15S can be cold solid. The mobility of ABS is related to both injection temperature and injection pressure, where the injection pressure is slightly more sensitive. Therefore, in the process of forming hand from the injection pressure to reduce the melt viscosity, improving the filling performance. ABS because of the different components, the performance of different water absorbent and adhesion, the adhesion and absorption of water between 0.2 ~ 0.5% and sometimes up to 0.3 ~ 0.8%, in order to get the products ideal for the drying process, before molding, the moisture content below 0,1%. Otherwise, the surface will appear on the silver bubble,.

- Q: What kind of units do you need to process plastic injection products?I own the business, there are plastic injection molding machine more than, can produce all kinds of plastic products, order ~ unit in Hangzhou ~!

- has a great competitive advantage in the city of Ji'nan, 5 sets of CNC machining center, CNC lathe 2 units, the company is Chinese FAW heavy truck, China, supporting services Joyoung electric lights, Lent, Qingdao's foreign trade and other well-known enterprises, and repeatedly won the title of excellent supplier,

- Q: What equipment? How much money do not.. at first. There are several sets of injection molding machine can be about 2... Mainly plastic injection molding. The ABS PA PE PP PVC... Etc. in this area. Please know that a friend told Kazakhstan. Thank you.

- How big is the product? How big is the injection machine? The machine has been bought. Waste of electricity and high price; the product made by buying small is not good. The injection machine 100 grams may in 6 to 8, in case Taiwan, {brand is not the same, the price difference is very big. } to do PA, if it is enhanced, it is necessary to do special screw and barrel, wear-resistant.

- Q: The plastic bottle processing plant needs those machines

- The plastic bottle processing into extrusion blow and injection blowing, equipment, plastic bottle blowing materials are not the same, PE and PVC are PET bottles are extrusion blowing, injection blowing.First of all, to have bottle blowing machine, bottle blowing machine must also have the injection stretch blow moulding machine, extrusion blow without.A crusher is a bottle that breaks down and is used to crush bottles and recycle waste materials.

Send your message to us

Large two-platen (Direct Hydraulic Clamping) Injection Moulding Machines

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 SET unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords